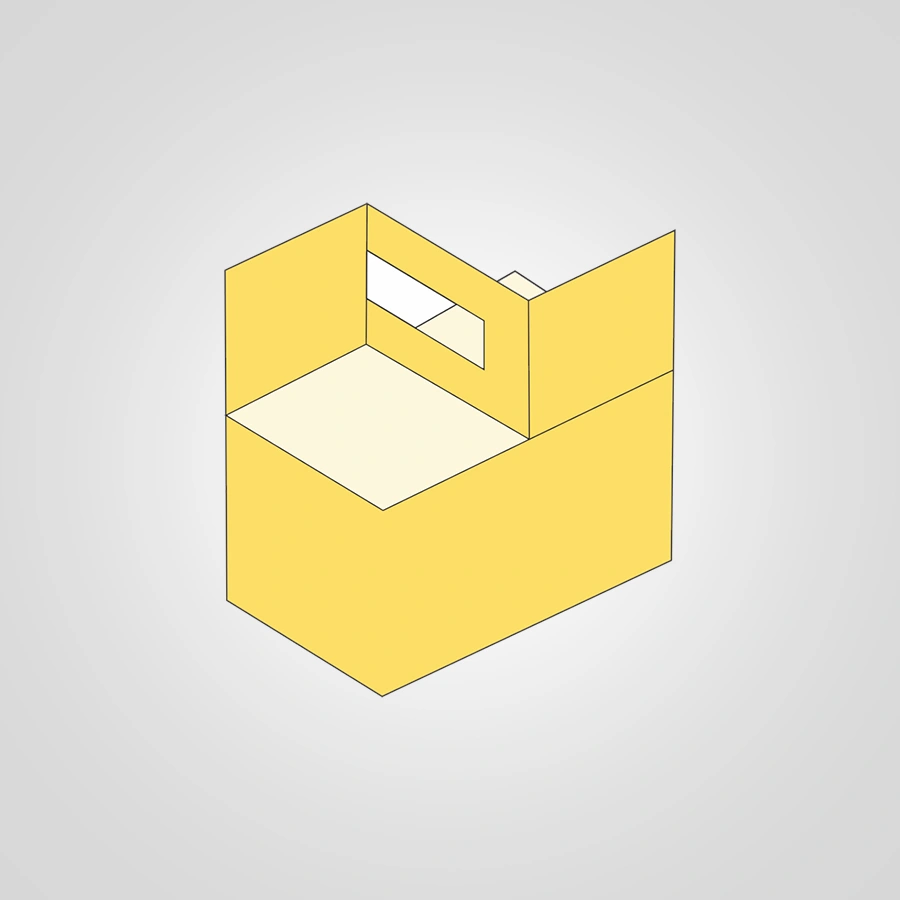

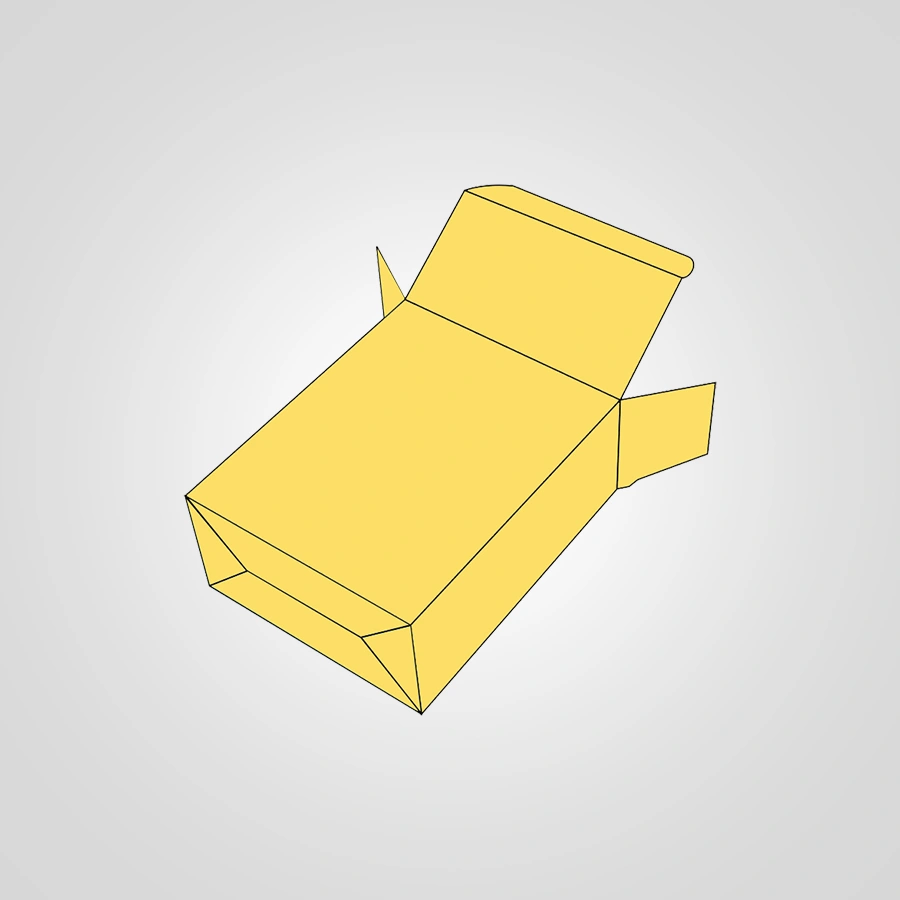

Full Flap Auto Bottom

We are a trusted Full Flap Auto Bottom Box Manufacturer and Supplier, providing comprehensive Wholesale solutions for heavy-duty packaging requirements. Our expertise includes creating durable Printed Full Flap Auto Bottom boxes that feature reinforced full-flap construction and secure automatic bottoms, making them ideal for industrial suppliers, manufacturers, and distributors shipping heavy or high-value products that require maximum protection during transit and handling.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Full Flap Auto Bottom Boxes | Maximum Strength Packaging | Haul Packaging

In the demanding world of industrial shipping and heavy product distribution, standard packaging often fails when put to the test. Boxes collapse under extreme weights, contents become damaged from insufficient protection, and inefficient assembly processes slow down operations. At Haul Packaging, we've engineered a solution that stands up to the toughest challenges: Full Flap Auto Bottom Boxes. This robust packaging design combines the unparalleled strength of full overlap construction with the time-saving efficiency of an automatic locking base, creating what many logistics professionals consider the ultimate workhorse for heavy-duty applications.

This comprehensive guide will explore the engineering principles, material science, and practical applications of Full Flap Auto Bottom Boxes. We'll demonstrate how this industrial-grade packaging solution can reduce product damage, improve operational efficiency, and provide the reliable performance that American businesses demand for their most challenging shipping needs.

For brands looking to pair industrial strength with elegant presentation, our Custom Two Piece Boxes offer premium versatility for both retail and protective packaging needs.

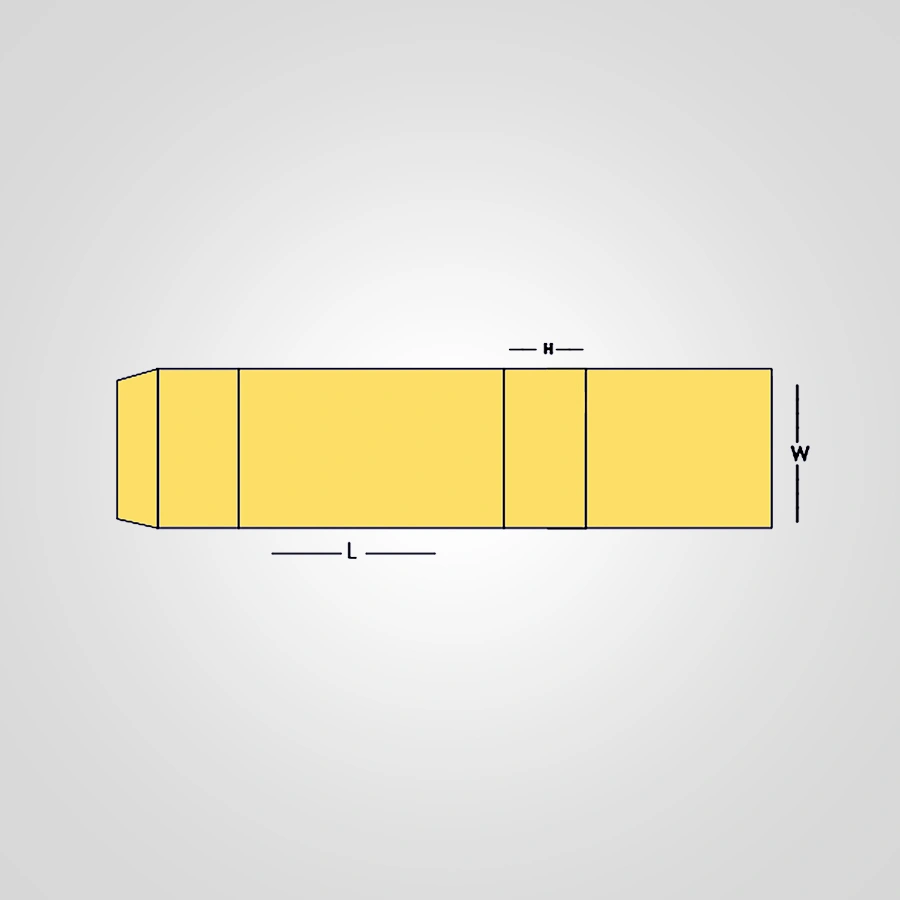

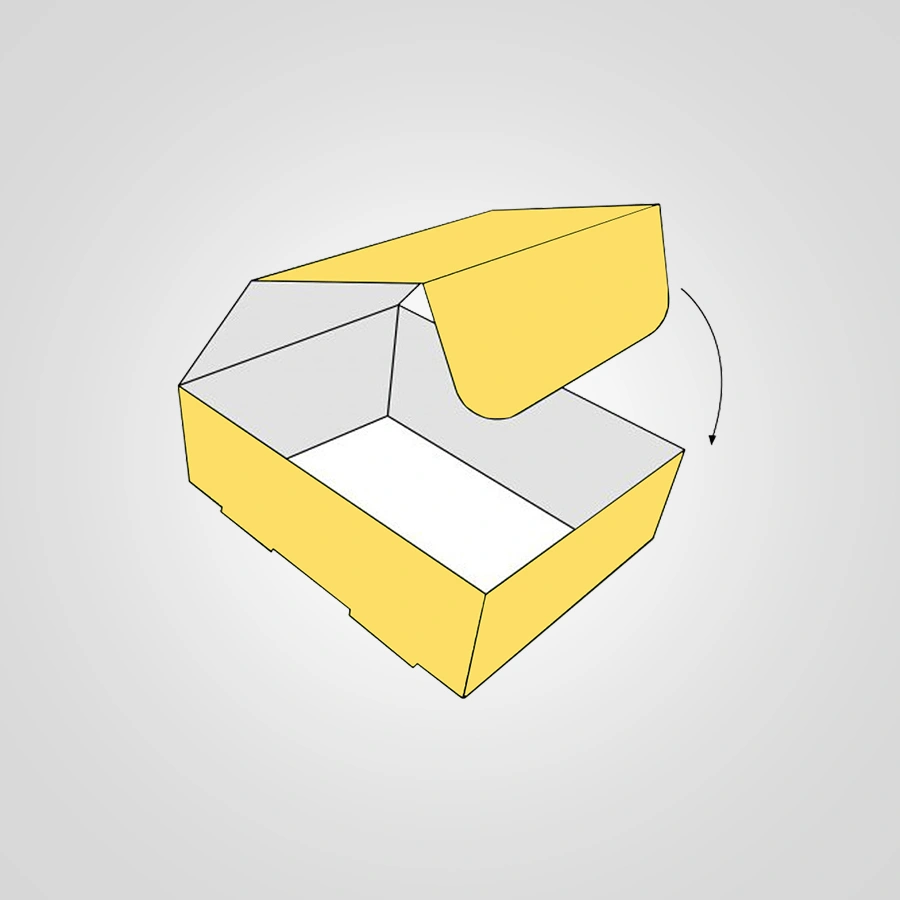

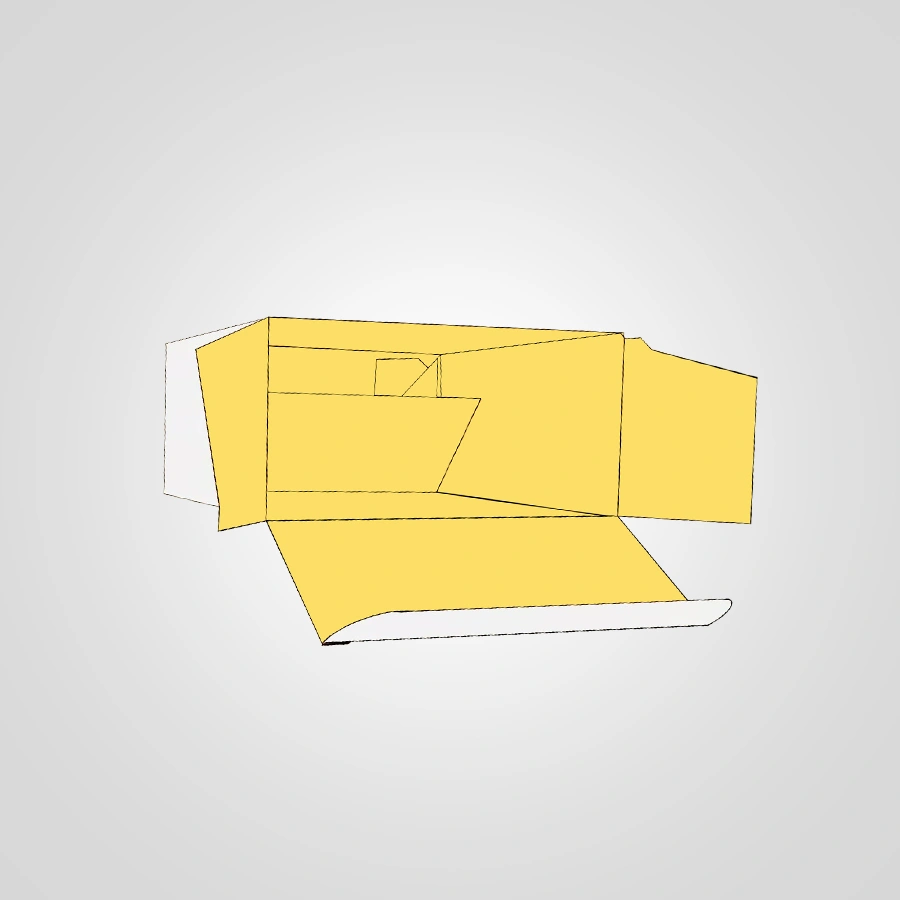

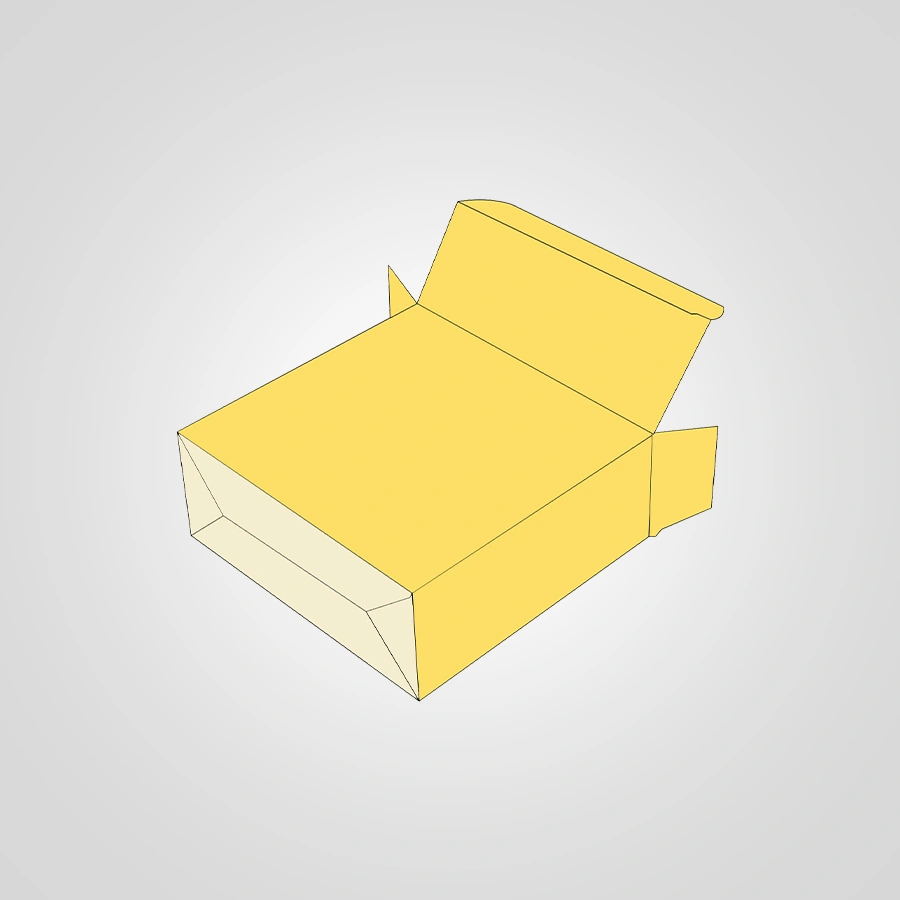

What Are Full Flap Auto Bottom Boxes?

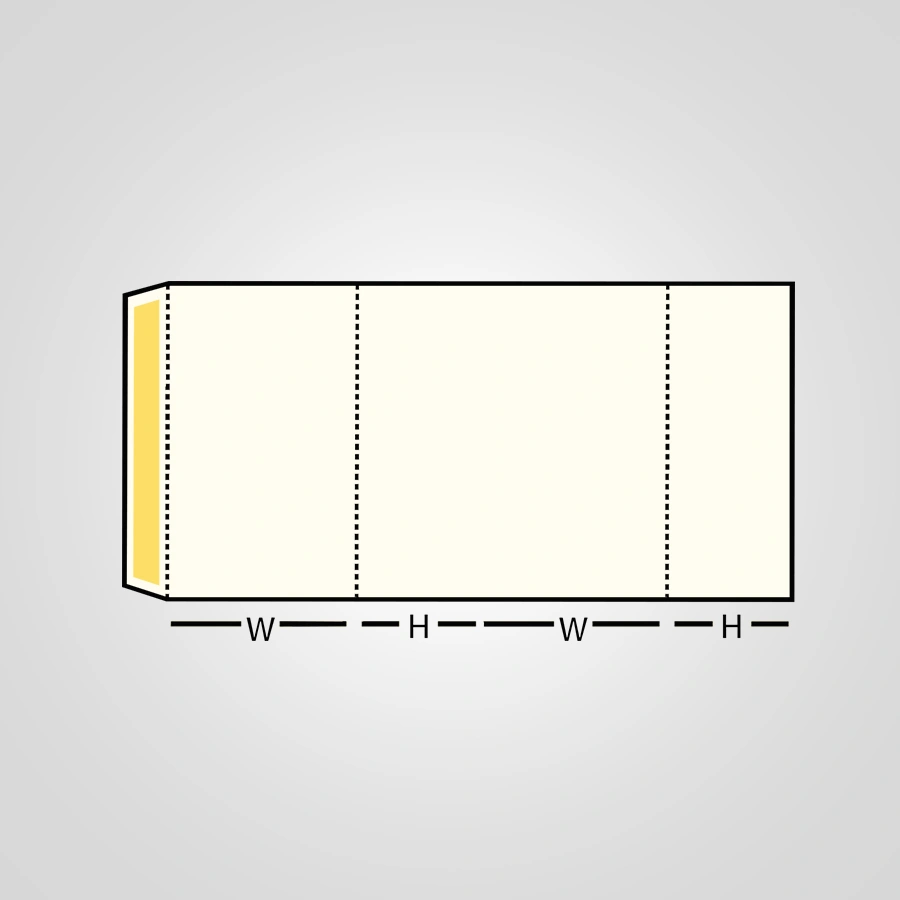

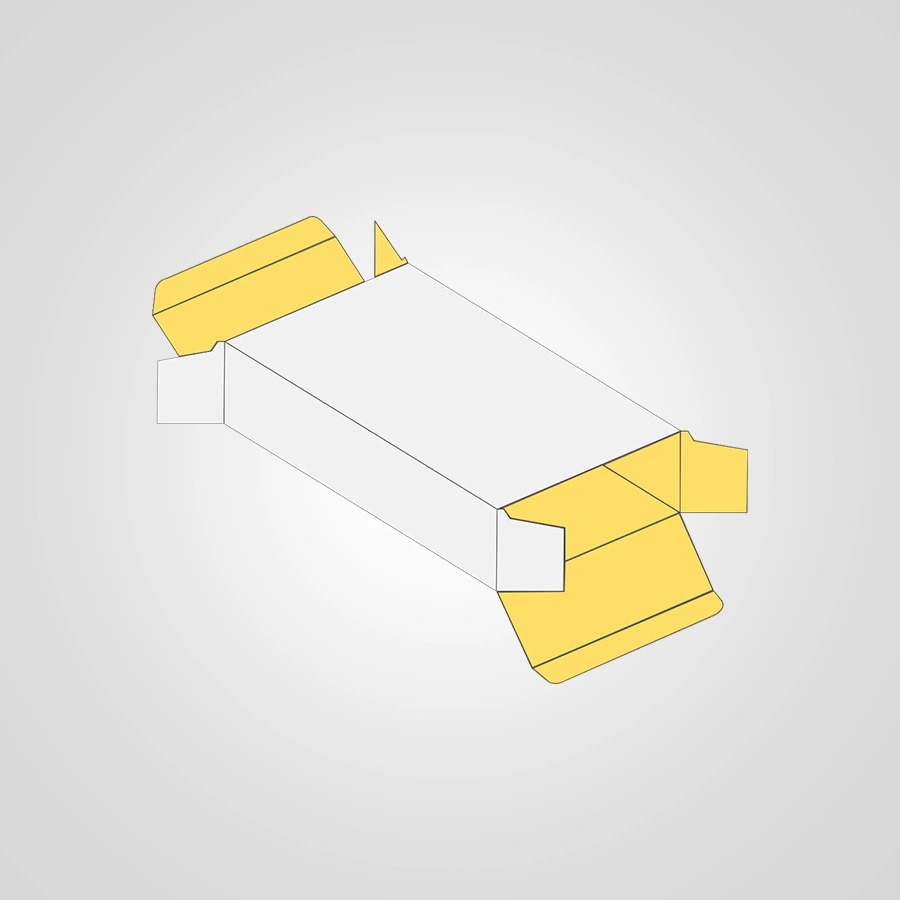

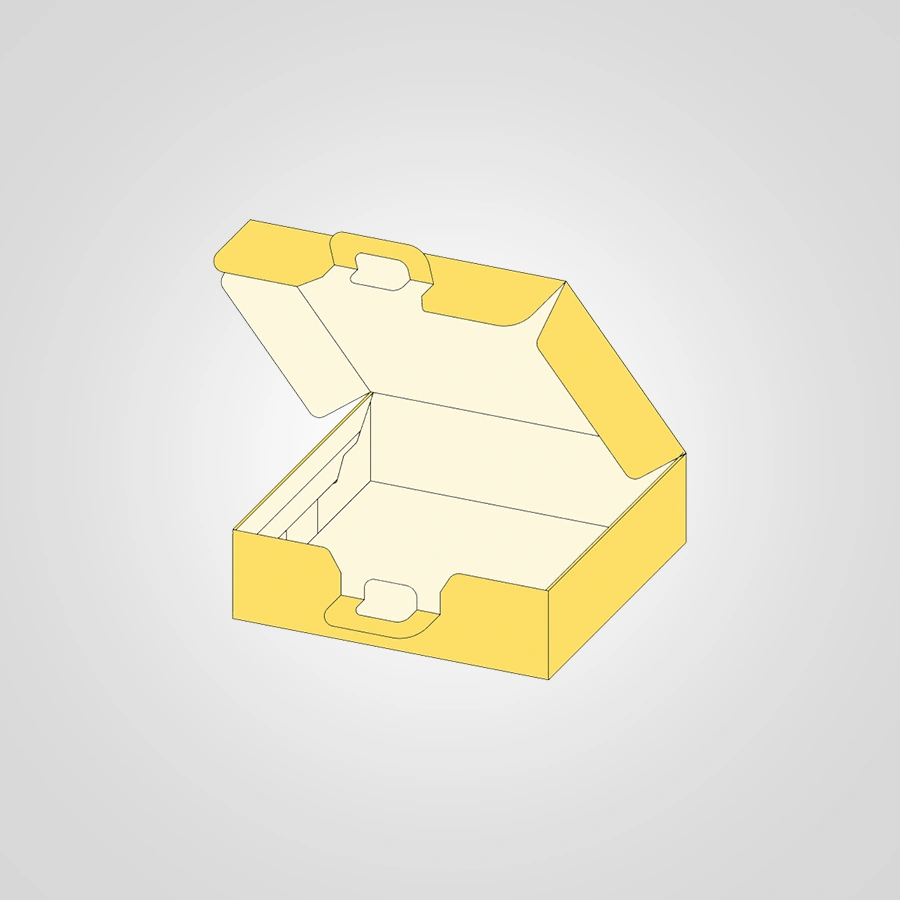

Full Flap Auto Bottom Boxes represent a specialized category of corrugated packaging defined by two distinct structural features that work together to create an exceptionally strong and efficient shipping container.

The design incorporates:

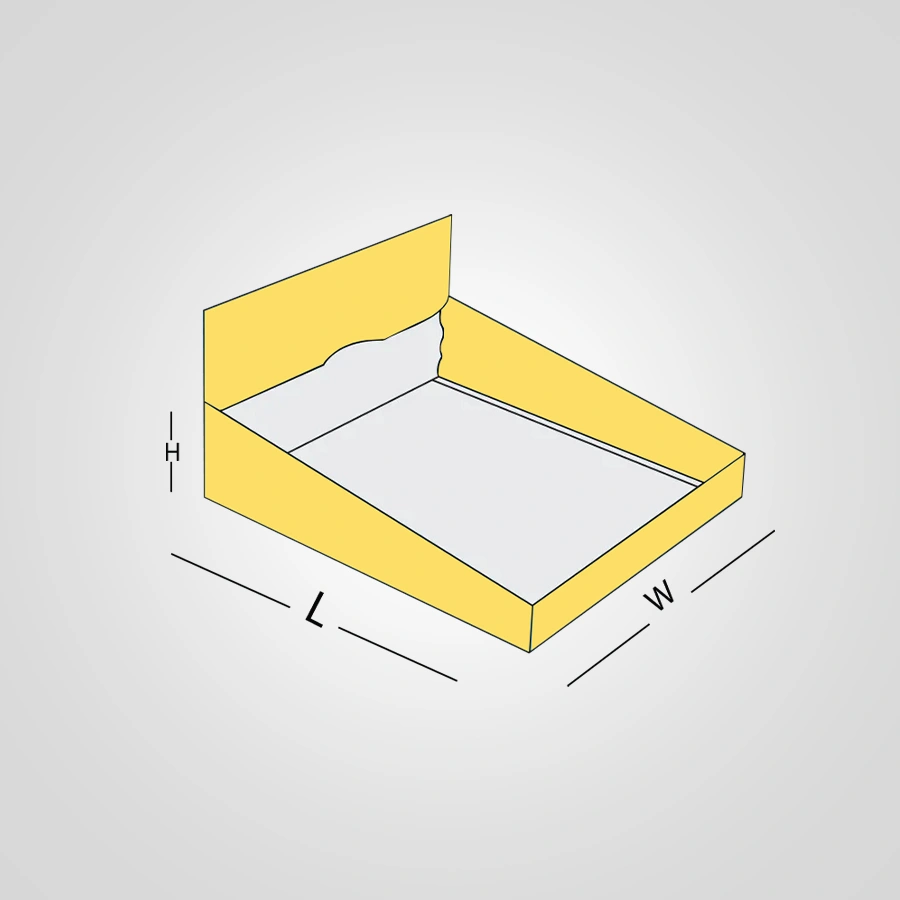

- Full Overlap Flaps (FOL): Both the top and bottom flaps extend fully to the opposite side of the box, creating a double-thick layer of protection and significantly increasing compression strength.

- Automatic Locking Bottom: An ingeniously engineered base that locks securely into place through a series of interlocking tabs and slots, requiring no tape or staples for base assembly.

- Reinforced Construction: Strategic scoring and folding patterns that maintain structural integrity under extreme weights and rough handling conditions.

This combination creates packaging that's specifically engineered for heavy, high-value, or fragile items that demand maximum protection throughout the supply chain.

Industries Served: Built for Demanding Applications

The exceptional strength and durability of full flap auto bottom boxes make them indispensable across multiple industries where packaging failure is not an option.

| Industry | Primary Use Case | Key Benefit |

| Industrial Manufacturing | Shipping machine parts, raw materials, and equipment between facilities. | Withstands the rigors of industrial handling and provides exceptional protection for high-value components. |

| Automotive & Aerospace | Packaging for precision components, tools, and replacement parts. | The full overlap design prevents crushing and protects sensitive parts from impact damage during transit. |

| E-commerce & Heavy Goods | Online sales of dense products like tools, fitness equipment, and hardware. | Provides superior protection during "last-mile" delivery where packages undergo significant handling. |

| Warehousing & Distribution | Palletized storage and shipping of heavy products in bulk quantities. | Exceptional stacking strength prevents box collapse in high-stack warehouse environments. |

| Furniture & Appliances | Shipping components, hardware, and smaller furniture items. | The automatic bottom speeds assembly while the full flaps provide necessary protection for finished goods. |

Materials & Construction: The Science of Superior Strength

The performance of Full Flap Auto Bottom Boxes depends on advanced material selection and precision engineering tailored to heavy-duty applications.

-

Corrugated Board Options:

- Single Wall Corrugated: Available in various flute profiles (B, C, E) for different strength and printing requirements.

- Double Wall Corrugated: Combining two layers of fluting (typically BC or EB flute) for maximum strength and durability.

- Triple Wall Corrugated: For the most extreme applications requiring the highest level of protection.

-

Board Strength Specifications:

- Edge Crush Test (ECT): Measures stacking strength, with higher ECT values (e.g., 44, 55, 65) indicating greater resistance to compression.

- Bursting Strength: Measures puncture resistance, important for rough handling environments.

- Board Grade: Combination of flute type and paper weight that determines overall performance characteristics.

-

Structural Engineering Features:

- Reinforced Score Lines: Precision scoring ensures clean, consistent folding without compromising material strength.

- Interlocking Tab Design: Engineered tabs and slots that create a secure, reliable lock without adhesives.

- Optimized Glue Patterns: Strategic adhesive application for consistent performance and durability.

To enhance packaging for beverages or bottled goods, consider the reinforced Glass Carrier solutions engineered for stability and safe transport.

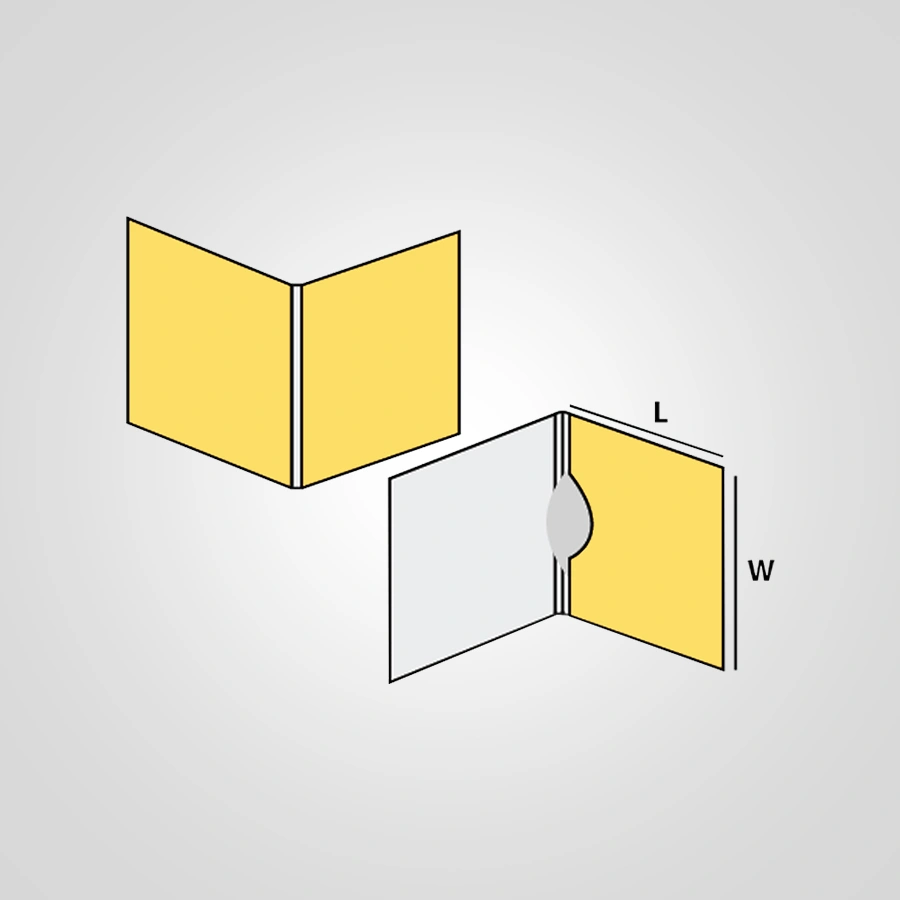

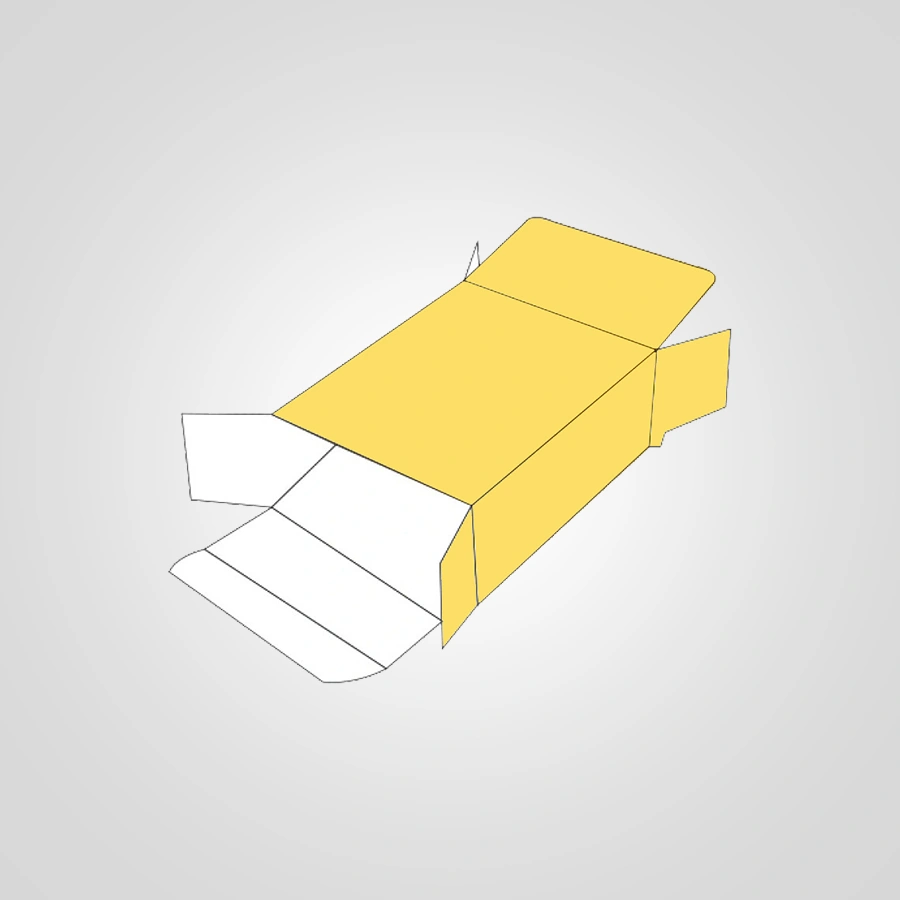

Box Styles & Configurations

While maintaining the core full flap auto bottom design, these boxes can be configured for specific applications:

- Standard FOL Auto Bottom: The classic design with full overlapping top and bottom flaps.

- Bliss Style Box: A variation with specific flap dimensions and scoring patterns.

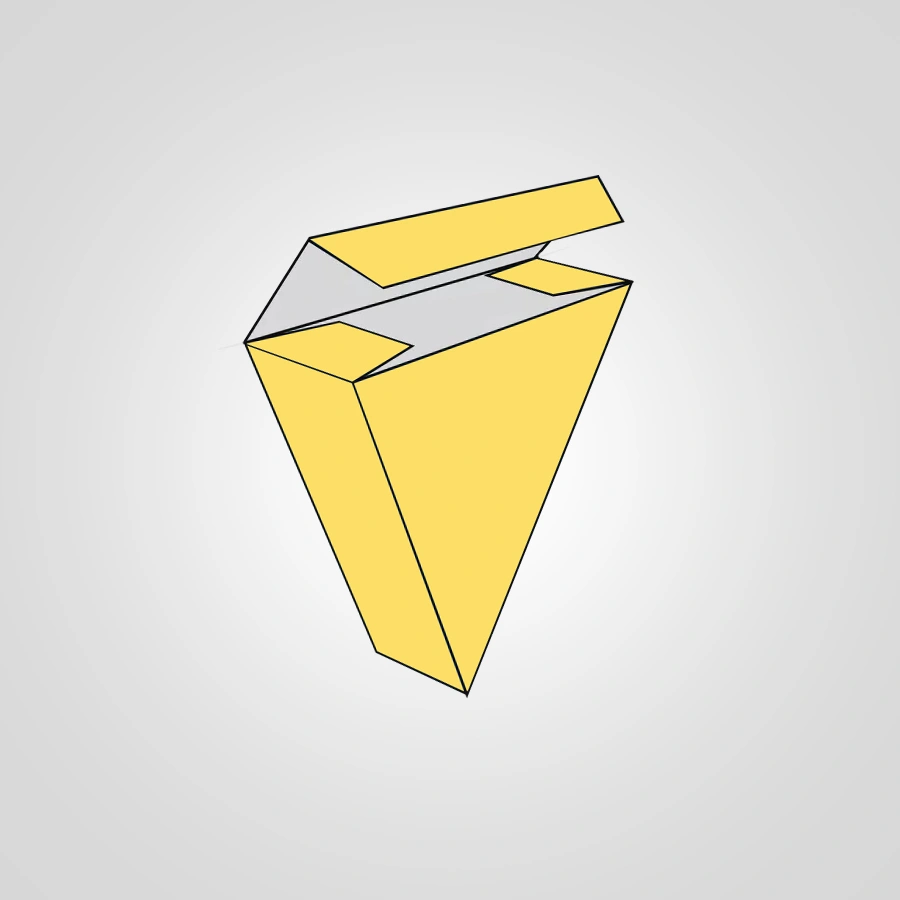

- Five-Panel Folder: Wraps the product completely, offering extra protection.

- Telescope Design: Two-piece construction for extra-deep products or added protection.

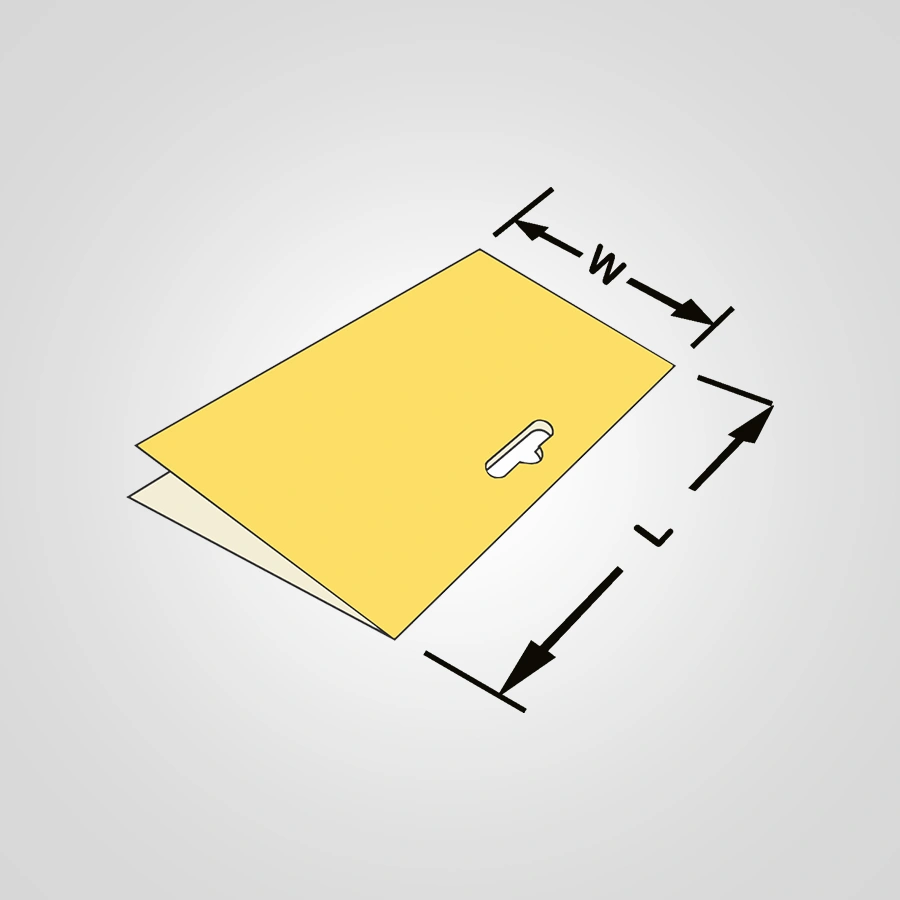

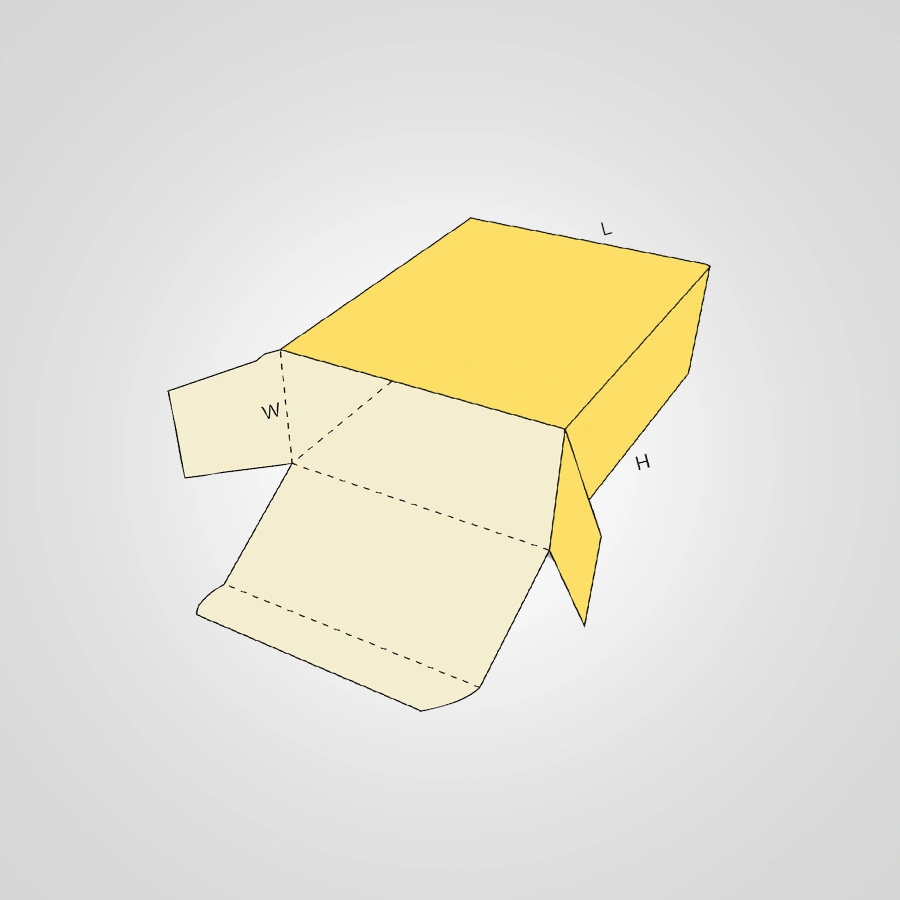

Sizes & Dimensions: Engineered for Optimal Performance

At Haul Packaging, we specialize in creating custom size full flap boxes that optimize both protection and cost-efficiency.

| Size Category | Common Dimensions (LxWxH) | Weight Capacity | Ideal Product Types |

| Small | 12" x 10" x 8" | 40-65 lbs | Machine parts, tools, automotive components |

| Medium | 18" x 14" x 12" | 65-95 lbs | Industrial supplies, multiple items, equipment parts |

| Large | 24" x 18" x 16" | 95-130 lbs | Heavy machinery parts, bulk components |

| Extra Large | 30" x 20" x 20" | 130-165 lbs | Large industrial items, palletized shipments |

For product lines that need clear labeling or retail-ready presentation, our Header Cards offer an ideal complement to your packaging strategy.

Custom Printing & Finishing: Functional Branding for Industrial Applications

While primarily functional, full flap auto bottom boxes offer practical opportunities for branding and communication.

-

-

Printing Processes:

- Flexographic Printing: The most common method for corrugated packaging, ideal for logos, handling instructions, and basic graphics.

- Digital Printing: Suitable for short runs with more detailed graphics or variable information.

-

-

Branding Applications:

-

- Company Logos & Information: Ensure brand recognition throughout the supply chain.

- Handling Instructions: Clear markings for "Fragile," "This Side Up," or specific handling requirements.

- Product Information: Contents, weights, or tracking information printed directly on the box.

- Safety Warnings: Important handling or safety information for hazardous materials.

Cost & Pricing: Investing in Damage Prevention

The cost of Full Flap Auto Bottom Boxes is an investment that pays dividends through reduced product damage, lower insurance claims, and improved operational efficiency.

Key Factors Influencing Cost:

- Quantity: Bulk orders significantly reduce the per-unit cost through manufacturing efficiencies.

- Materials: The choice of corrugated board (single wall, double wall, triple wall) and ECT rating are primary cost drivers.

- Printing: Basic one or two-color printing is economical, while full-color graphics add cost but enhance brand presence.

- Size & Complexity: Larger boxes and custom designs require more material and manufacturing time.

Sample Pricing Table (for estimation purposes only):

| Quantity | 200# Test, Single Wall (1-Color Print) | 44 ECT, Double Wall (2-Color Print) |

| 500 Units | ~ $2.75 - $4.25 per unit | ~ $4.50 - $6.75 per unit |

| 1,000 Units | ~ $1.95 - $3.25 per unit | ~ $3.25 - $5.25 per unit |

| 5,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why Full Flap Auto Bottom Boxes Deliver Superior Value

- Regular Slotted Containers (RSCs): Provides significantly better top and bottom compression strength, reducing box failure in high-stack environments.

- Taped Boxes: The automatic bottom eliminates taping labor and material costs while providing more consistent base security.

- Wood Crates: Offers similar protection at a fraction of the weight and cost, with easier assembly and disposal.

Why Choose Haul Packaging for Your Industrial Boxes?

- USA-Based Manufacturing Expertise: We understand American industrial standards and supply chain requirements.

- Strength Engineering: We help select the optimal board grade and construction for your specific weight and handling requirements.

- Quality Assurance: Every production run is tested for compression strength and assembly reliability.

- Reliable Supply Chain: Consistent delivery schedules to support your manufacturing and shipping operations.

Frequently Asked Questions (FAQ)

Q: How much weight can full flap auto bottom boxes hold?

A: The weight capacity depends on the corrugated board specification and box dimensions. Our standard 200# test single-wall boxes typically handle 40-65 lbs, while double-wall constructions can support 65-165 lbs or more. We can engineer solutions for specific weight requirements.

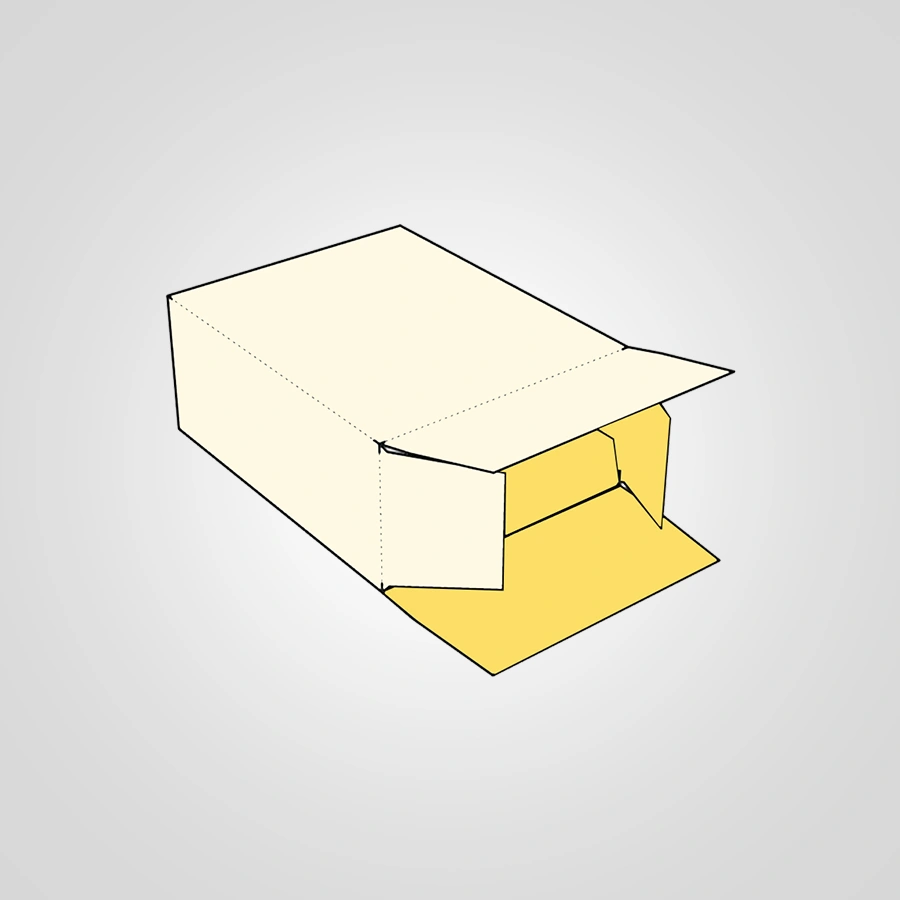

Q: Are these boxes difficult to assemble?

A: Not at all! The automatic bottom is designed for quick, intuitive assembly. Most boxes can be set up in 10-15 seconds with minimal training. The interlocking tabs create a secure base without tape or tools.

Q: Can I get a sample to test with my products?

A: Absolutely! We strongly encourage ordering a full flap box sample to evaluate the strength, test the assembly, and ensure it meets your requirements. Contact us to arrange samples.

Q: How do I determine the right box strength for my product?

A: Consider your product weight, stacking requirements, and handling conditions. Our packaging experts can help you select the appropriate ECT rating and board construction based on your specific needs.

Ready to Solve Your Heavy-Duty Packaging Challenges with Haul Packaging?

Stop accepting packaging failures as a cost of doing business. At Haul Packaging, Choose Full Flap Auto Bottom Boxes to protect your valuable products, streamline your operations, and ensure your shipments arrive in perfect condition every time.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |