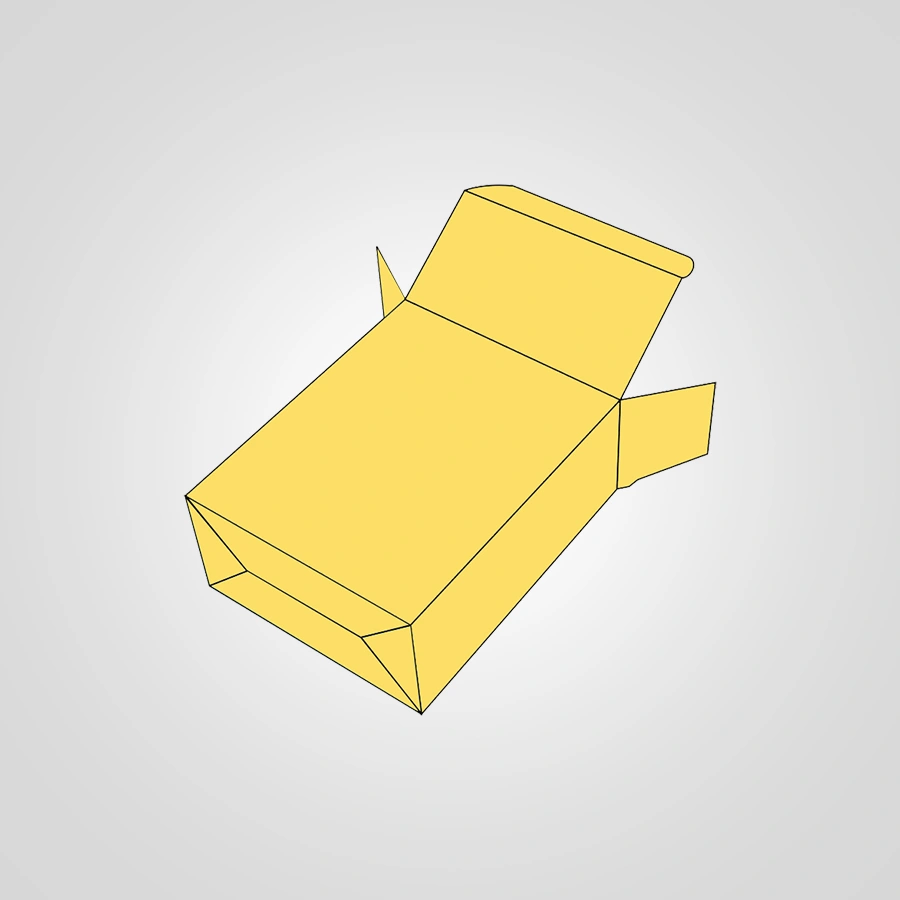

Seal End Auto Bottom Boxes

We are a trusted Seal End Auto Bottom Boxes Manufacturer and Supplier, providing comprehensive Wholesale solutions for streamlined packaging operations. Our Printed Seal End Auto Bottom Boxes feature high-quality branding that enhances your product's visibility while providing the practical benefits of automatic bottom assembly and secure seal-end closure for optimal protection.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Seal End Auto Bottom Boxes | Secure & Efficient Packaging | Haul Packaging

In today's fast-paced commerce environment, packaging must achieve the perfect balance between operational efficiency and product security. Traditional packaging often forces businesses to choose between speed and protection, leading to either labor-intensive processes or vulnerable shipments. At Haul Packaging, we've engineered the solution that eliminates this compromise: Seal End Auto Bottom Boxes. This sophisticated packaging style combines the time-saving automation of a self-locking base with the tamper-resistant security of permanently sealed ends, creating what many logistics professionals consider the ideal packaging system for modern American businesses.

This comprehensive guide will explore the engineering principles, material science, and practical applications of Seal End Auto Bottom Boxes. We'll demonstrate how this hybrid packaging solution can transform your operations by reducing labor costs, enhancing product protection, and delivering the reliable performance that today's competitive marketplace demands.

Looking for minimal yet sleek product wraps? Check out our Sleeves Only a perfect choice for elegant branding and retail presentation.

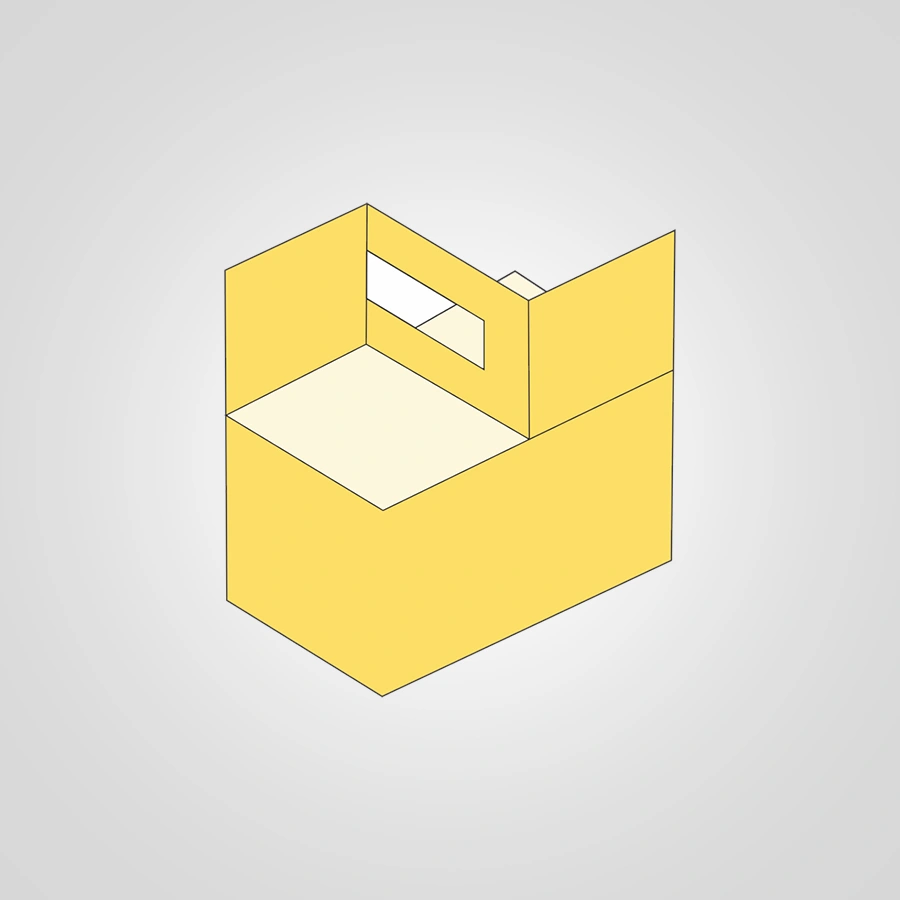

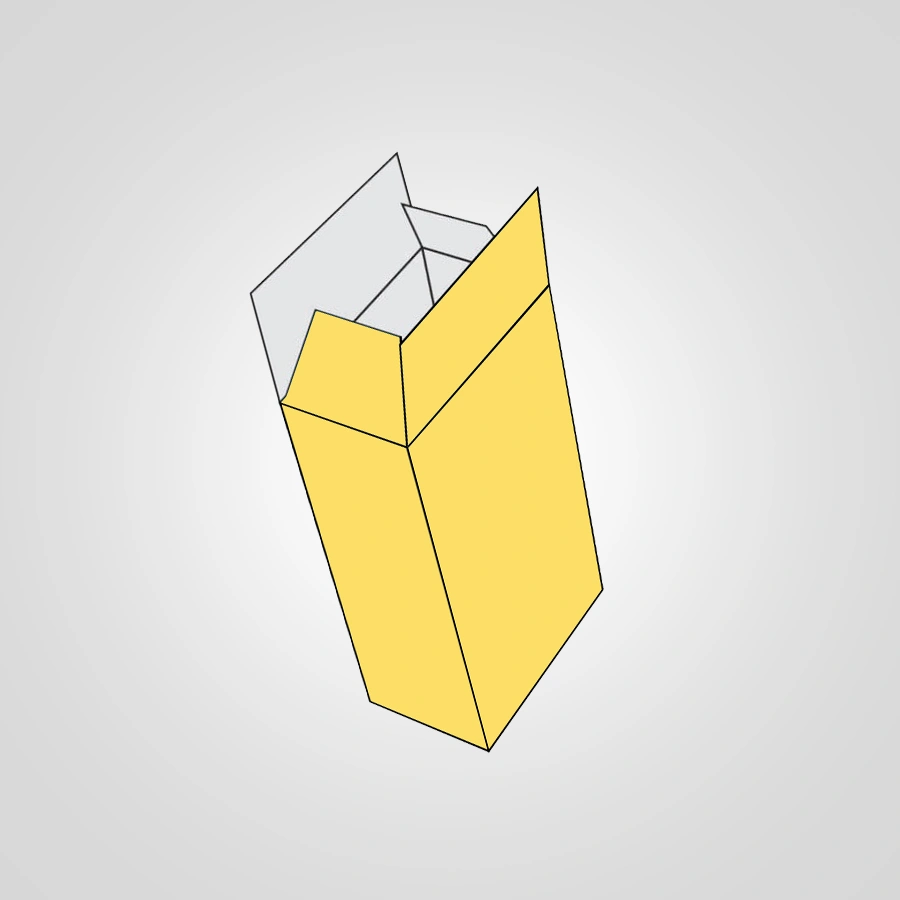

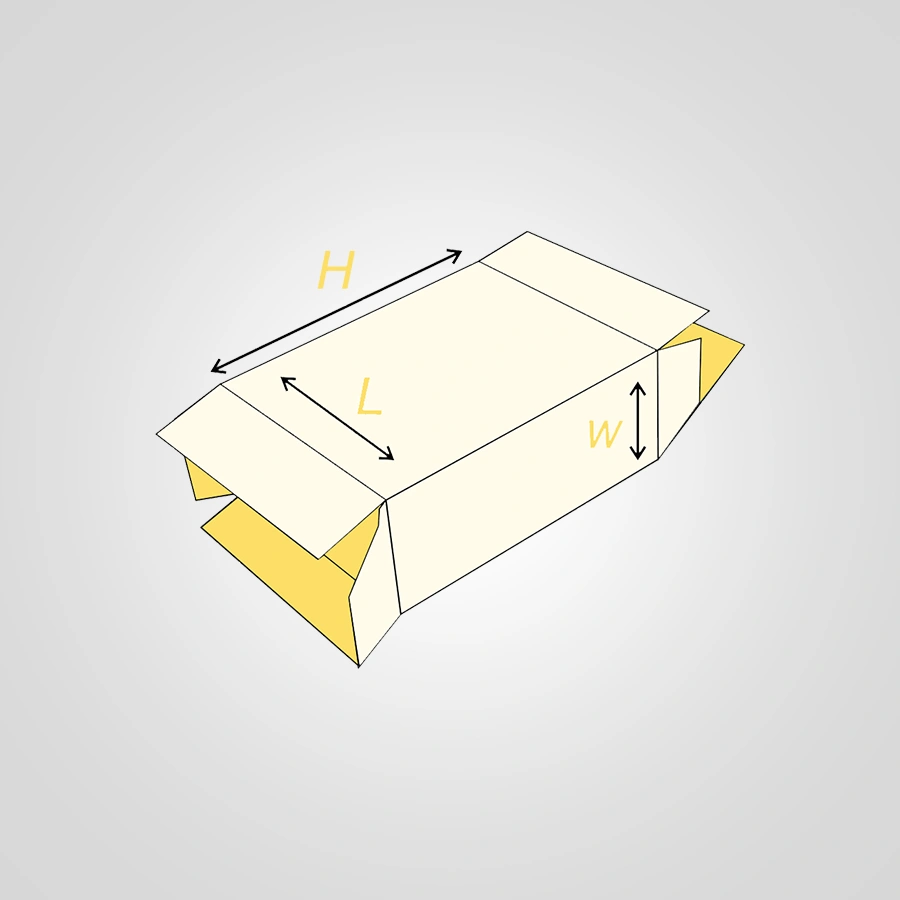

What Are Seal End Auto Bottom Boxes?

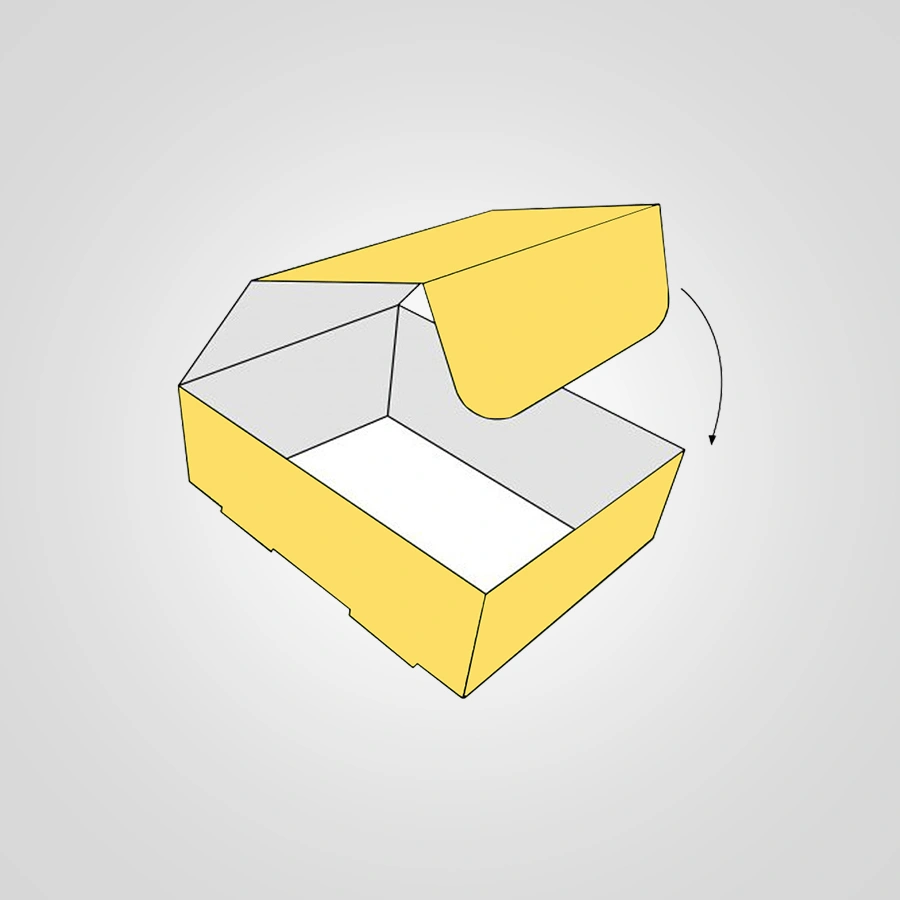

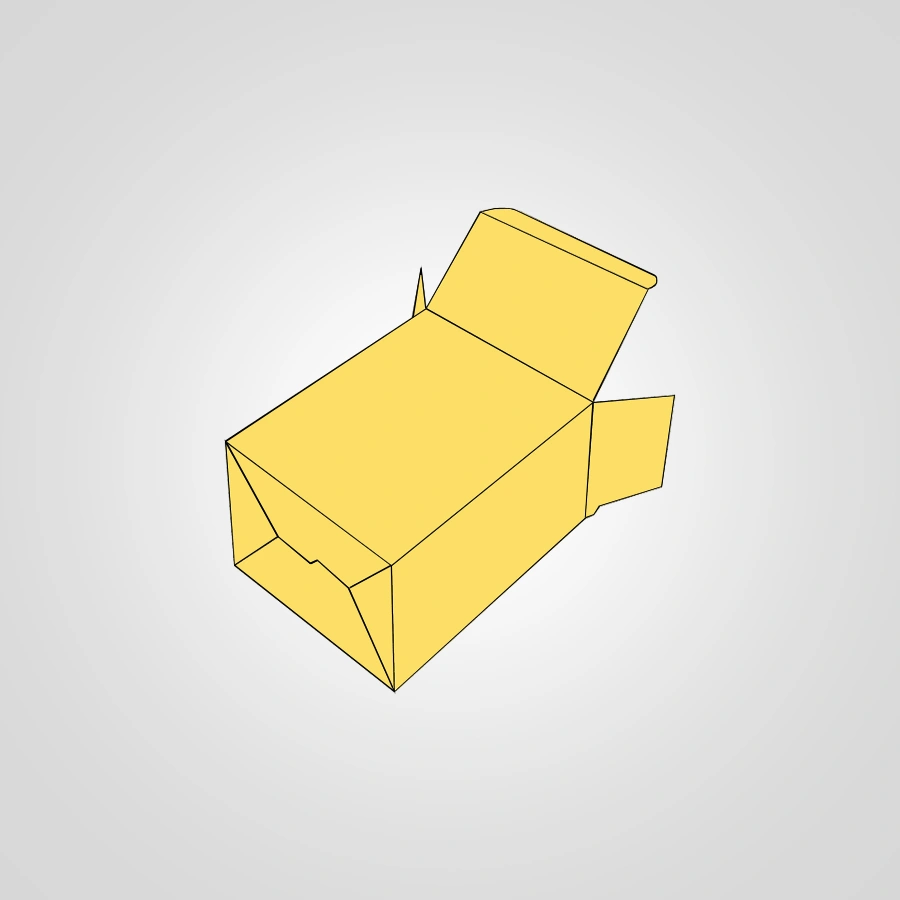

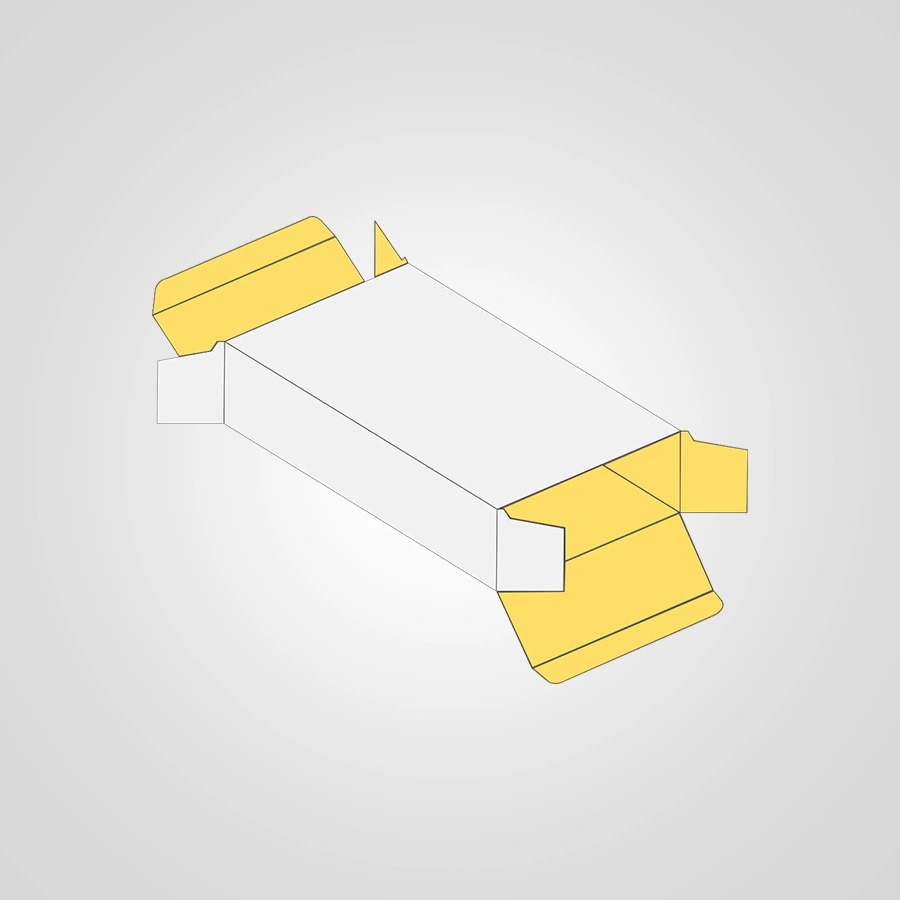

Seal End Auto Bottom Boxes represent an advanced packaging system that merges two superior closure mechanisms into one highly functional design. This innovative approach addresses both assembly efficiency and shipping security in a single, cohesive package.

The system features:

- Automatic Locking Bottom: An ingeniously engineered base that assembles in seconds through a simple fold-and-lock mechanism, requiring no tape, staples, or adhesives for base assembly

- Permanently Sealed Ends: The box ends are designed to be sealed with glue or tape, creating a tamper-resistant barrier that protects contents throughout the supply chain

- Rigid Construction: When assembled, the box forms a durable, structurally sound container that maintains its shape under normal shipping conditions

- Precision Engineering: Clean, crisp folds and exact tolerances ensure consistent performance and professional appearance

This combination creates packaging that's both incredibly efficient to set up and exceptionally secure once sealed, making it ideal for both manual packing lines and high-speed automated equipment.

For products needing top and bottom tuck closures, our Straight Tuck End Boxes offer excellent presentation and ease of use.

Industries Served: The Workhorse of Modern Commerce

The unique combination of efficiency and security makes these boxes indispensable across multiple sectors where both speed and product protection are critical.

| Industry | Primary Use Case | Key Benefit |

| E-commerce & Direct-to-Consumer | Shipping everything from apparel and accessories to electronics and home goods directly to customers | The automatic bottom speeds up fulfillment, while the seal end ensures products arrive securely, reducing damage claims and returns |

| Subscription Box Services | As the primary container for monthly curated product collections across various niches | Fast assembly supports high-volume packing schedules, and the secure closure maintains product integrity throughout delivery |

| Food & Beverage Packaging | Dry goods, gourmet foods, specialty food items, and confectionery products | The sealed ends provide an additional barrier against contaminants and pests while maintaining product freshness |

| Cosmetics & Beauty Products | Skincare sets, makeup collections, fragrances, and beauty accessories | The professional finish enhances brand perception while the secure closure provides customer confidence in product purity |

| Pharmaceutical & Healthcare | Over-the-counter medications, health supplements, and medical devices | The tamper-evident nature of the sealed ends meets industry standards for product safety and integrity |

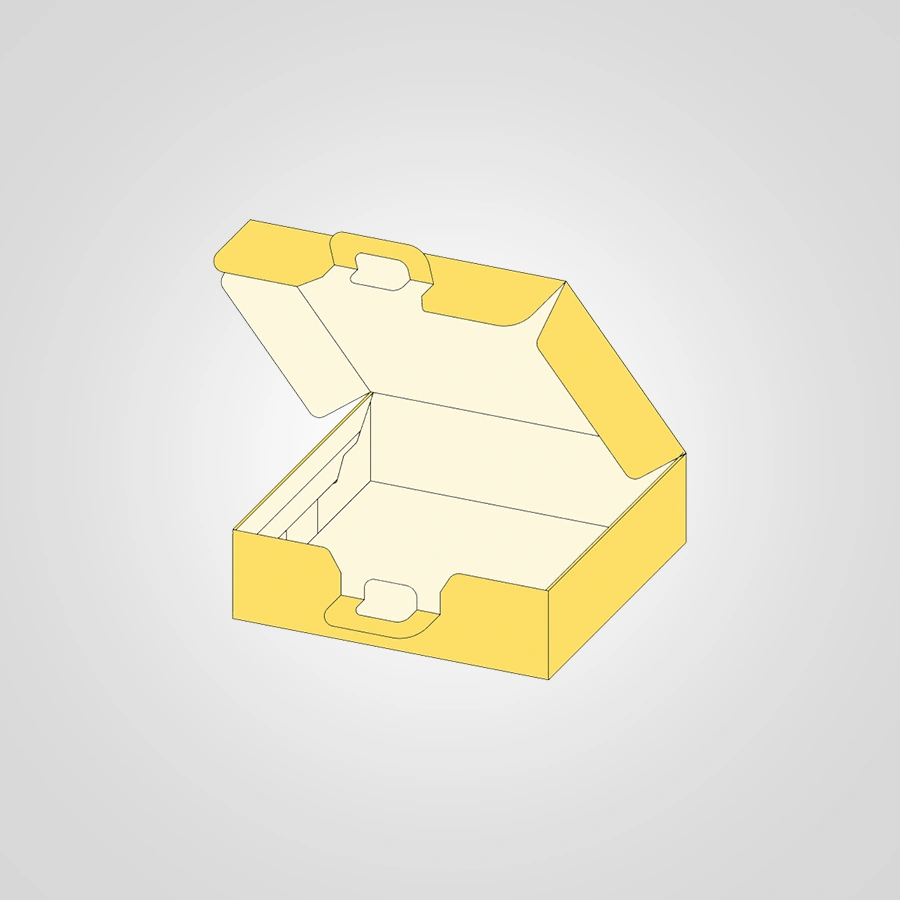

Need durable handle-style options for portable kits or premium gifts? Explore our Suitcase Boxes designed for both strength and style.

Materials & Construction: Engineered for Performance and Protection

The reliability of Seal End Auto Bottom Boxes depends on premium materials and precise manufacturing tolerances that ensure consistent performance.

-

Paperboard Grades:

-

-

- SBS (Solid Bleached Sulfate): The premium choice for retail packaging. This bright white, coated board provides the perfect surface for high-quality printing and vibrant brand colors.

- CCNB (Clay-Coated News Back): A cost-effective option with a brilliant white printable exterior and grey recycled interior. Excellent for e-commerce shipping where both appearance and budget matter.

- Kraft Paperboard: The go-to for eco-friendly packaging, offering a natural, rustic appearance and strong environmental credentials.

- Recycled Board: Contains post-consumer waste content, appealing to sustainability-focused brands and consumers.

-

-

Structural Engineering:

-

- Precision Die-Cutting: Ensures the automatic bottom mechanism functions flawlessly with crisp, clean folds every time

- Reinforced Locking Tabs: Critical stress points are engineered for durability and repeated reliability

- Optimized Glue Flaps: Designed for consistent adhesive application and strong bond formation

- Compression-Resistant Corners: Enhanced corner design prevents blow-outs during rough handling

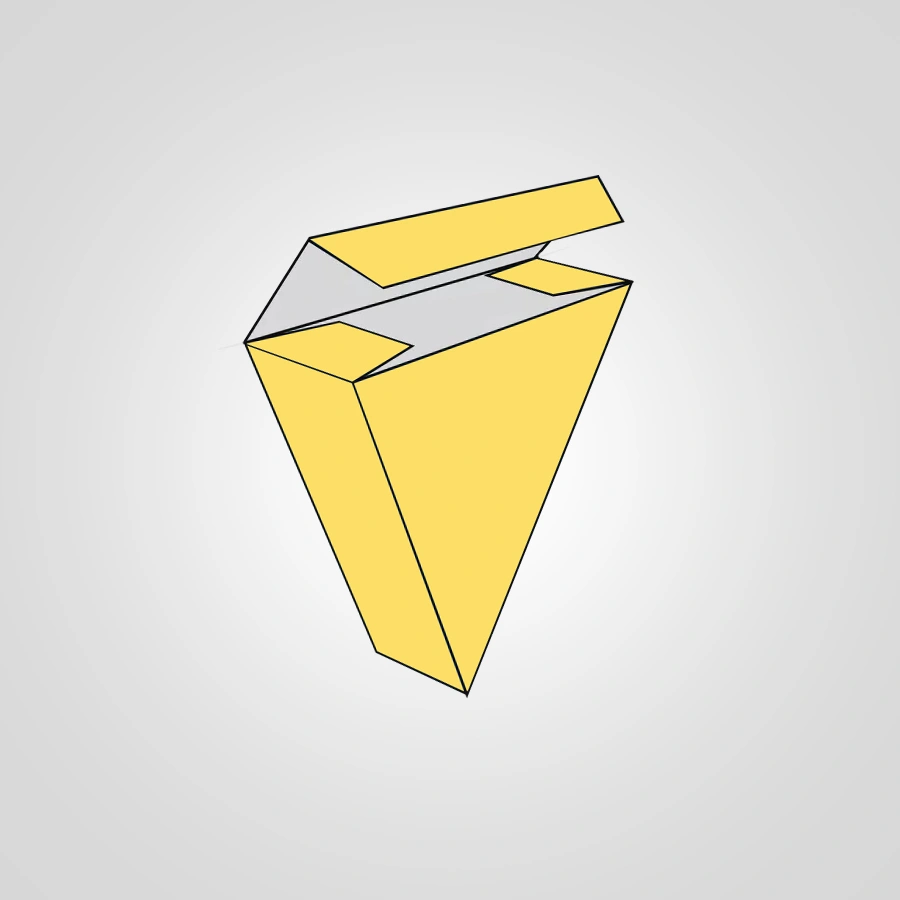

If you prefer eye-catching geometric styles, our Triangle Boxes add a unique visual twist to your product line.

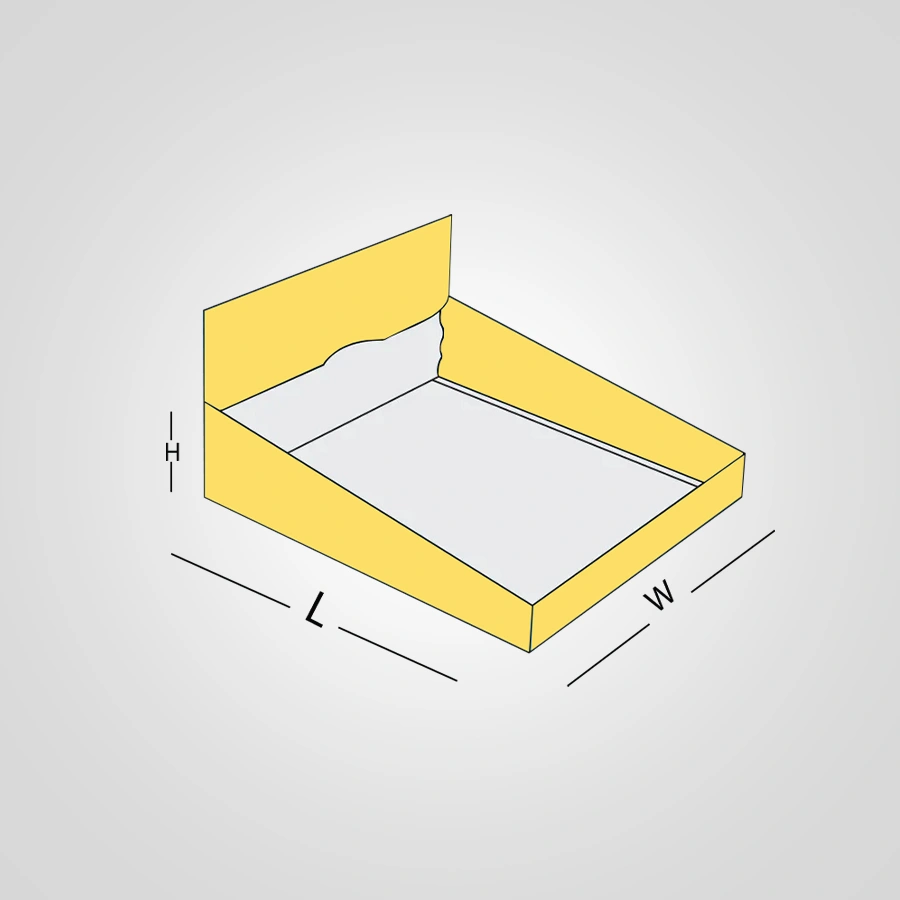

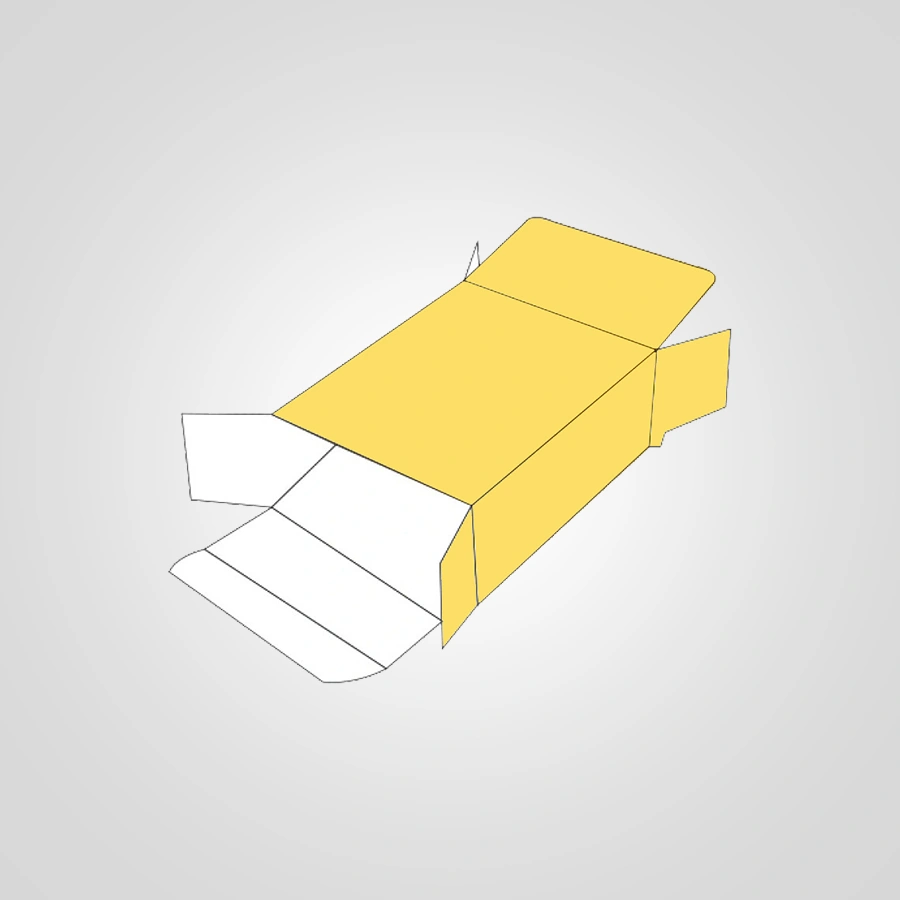

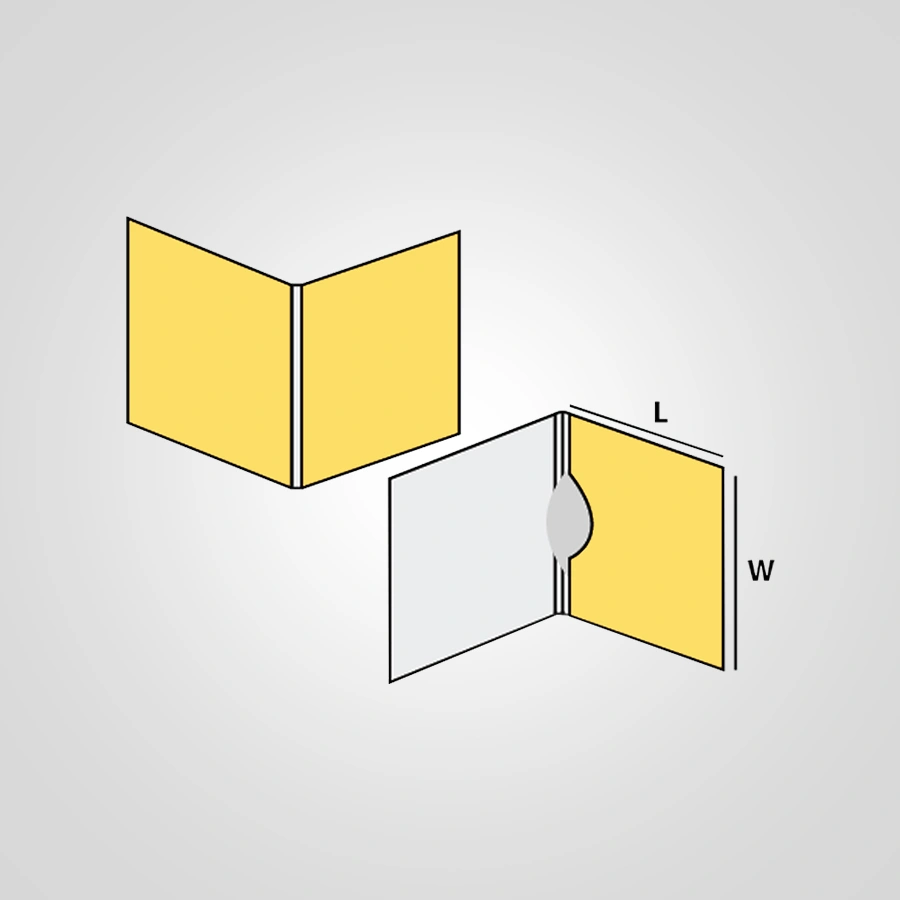

Box Styles & Configurations

While maintaining the core seal end auto bottom design, these boxes can be configured to match specific product and branding requirements.

- Straight Tuck Top: The most common style, with a straight front panel that tucks into the box front

- Reverse Tuck Top: Features tabs that tuck toward the back of the box, creating a clean front presentation ideal for retail

- Double-Wall Construction: For heavy or fragile items requiring extra protection and rigidity

- Full Overlap Seal End: Extended flaps that provide extra stacking strength for heavy products

For a blend of automation and top-tuck efficiency, explore our Tuck End Auto Bottom Boxes engineered for speed and presentation.

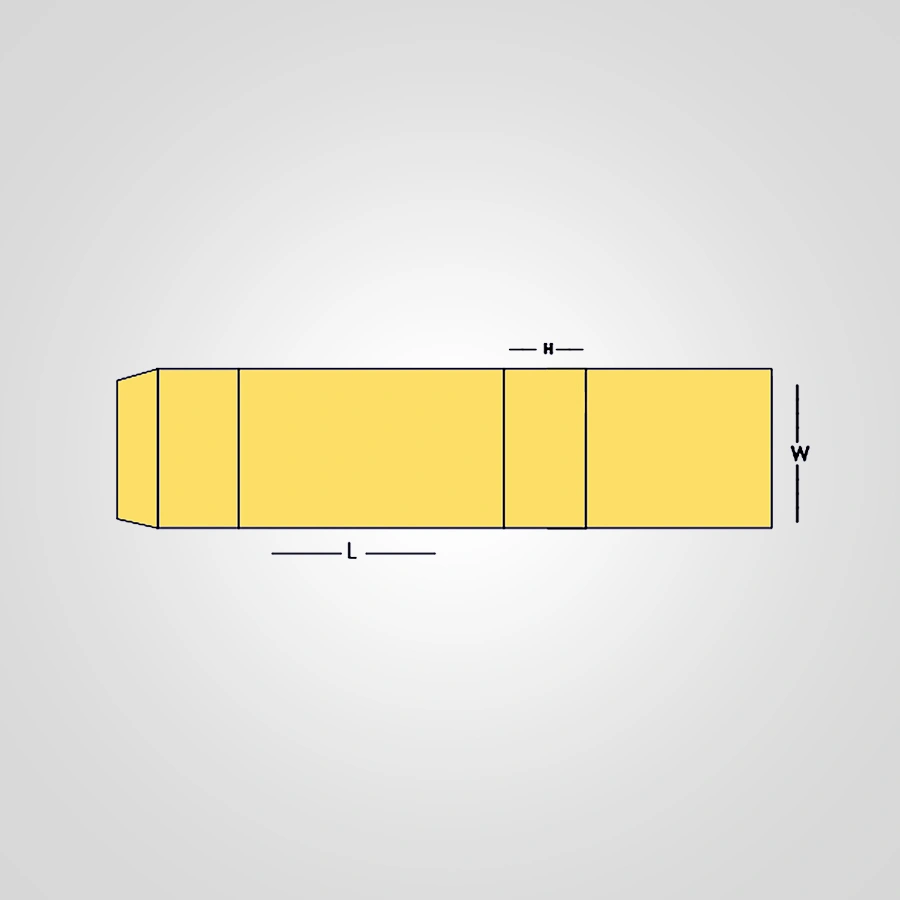

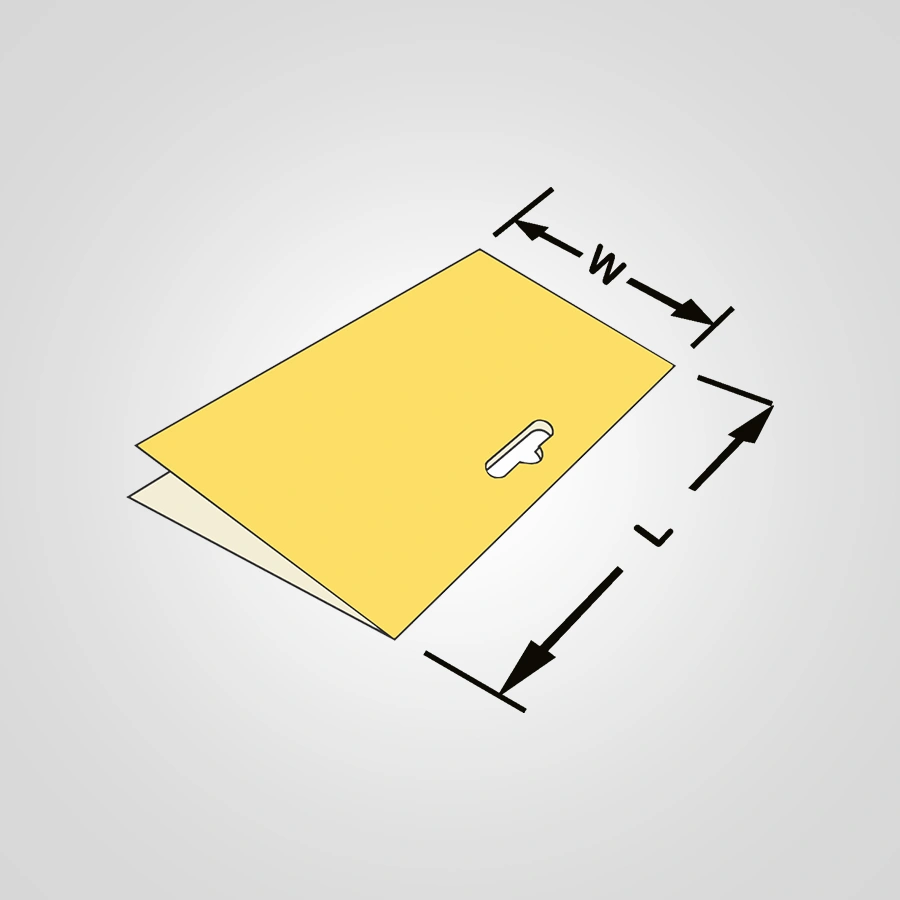

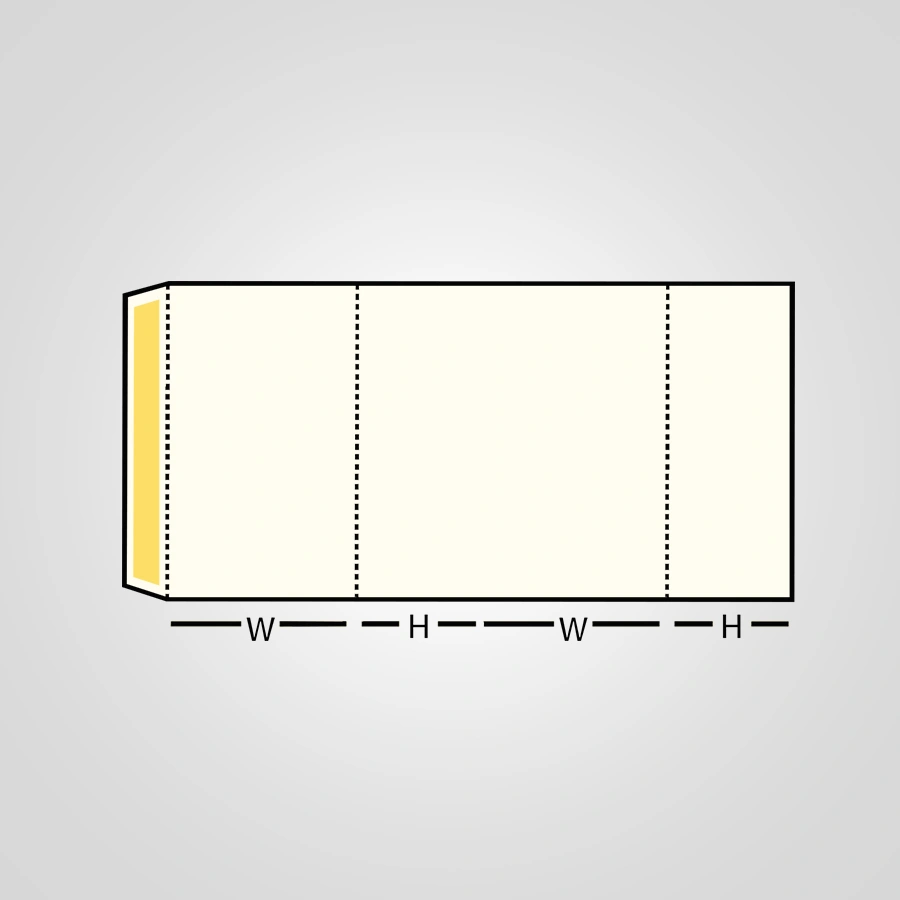

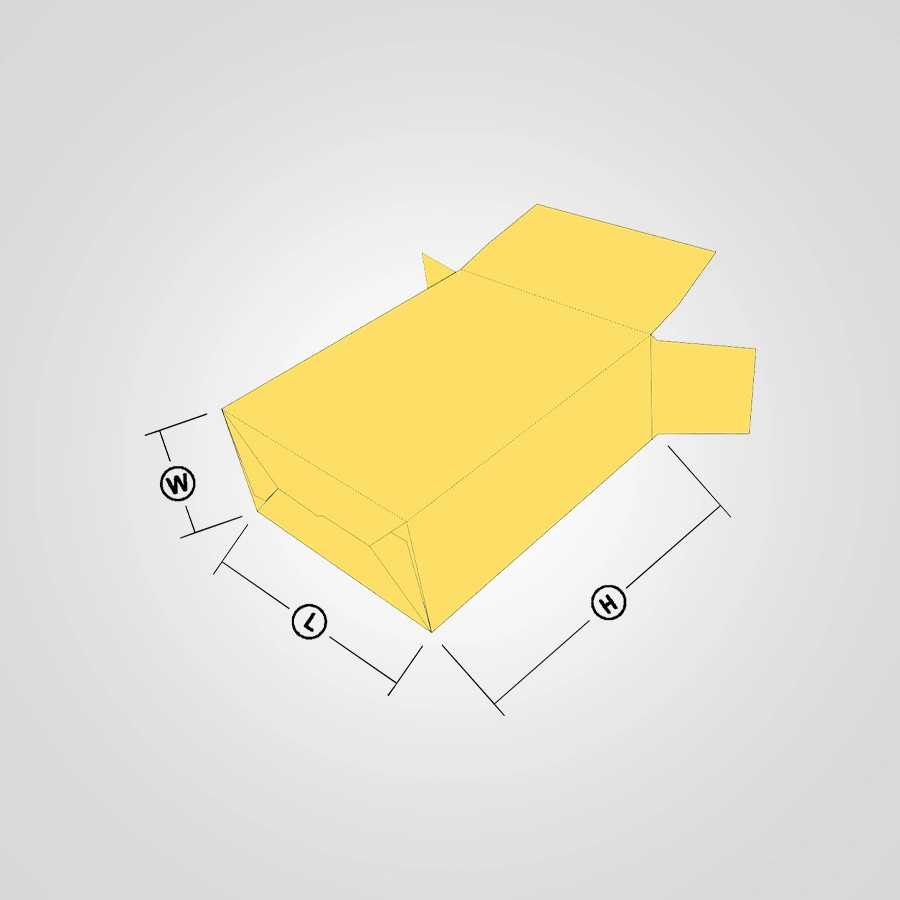

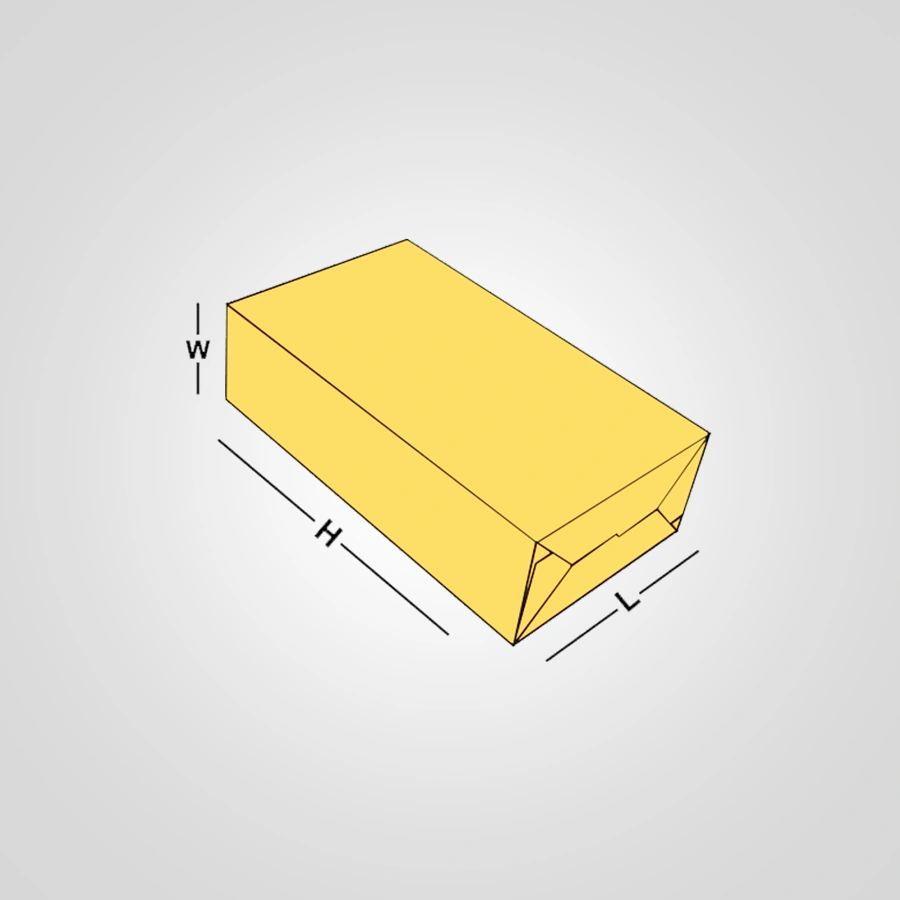

Sizes & Dimensions: Precision Engineering for Perfect Fit

At Haul Packaging, we specialize in creating truly custom size boxes that optimize material usage and provide perfect product fit.

| Size Category | Common Dimensions (LxWxH) | Ideal Product Types |

| Small | 6" x 4" x 2" | Jewelry, small electronics, cosmetics, samples |

| Medium | 10" x 8" x 4" | Books, apparel, beauty kits, food packages |

| Large | 14" x 10" x 6" | Shoes, multiple items, larger retail products |

| Extra Large | 18" x 12" x 8" | Bulk items, premium gifts, subscription boxes |

All dimensions can be fully customized to your exact specifications, ensuring optimal fit and minimal wasted space.

Custom Printing & Finishing: Professional Brand Presentation

The large, flat surfaces of seal end auto bottom boxes provide excellent opportunities for branding and communication.

-

Printing Processes:

-

-

- Offset Printing: Delivers the highest quality for custom printing, with sharp detail and precise color matching across all panels

- Flexographic Printing: A cost-effective solution for larger runs with simpler designs and spot colors

-

-

Premium Finishing Options:

-

- Aqueous Coating: Provides a protective, scuff-resistant layer that enhances color vibrancy

- Foil Stamping: Adds metallic accents to your logo or design elements for a premium look

- Embossing/Debossing: Creates tactile texture that adds depth and sophistication to your packaging

- Spot UV: Creates glossy, raised areas that contrast with matte surfaces for visual interest

Cost & Pricing: Investing in Operational Efficiency

The cost of Seal End Auto Bottom Boxes is an investment that pays for itself through reduced labor costs, minimized product damage, and enhanced brand perception.

Key Factors Influencing Cost:

- Quantity: Bulk orders significantly reduce the per-unit cost through manufacturing efficiencies

- Materials: The choice between SBS, CCNB, or Kraft paperboard directly impacts pricing

- Printing: Basic one-color printing is economical, while full color printing and specialty finishes add cost but significant marketing value

- Size: Larger boxes require more material

Sample Pricing Table (for estimation purposes only):

| Quantity | CCNB Paperboard (2-Color Print) | SBS Paperboard (Full Color + AQ Coating) |

| 1,000 Units | ~ $1.25 - $2.00 per unit | ~ $1.75 - $2.75 per unit |

| 5,000 Units | ~ $0.85 - $1.40 per unit | ~ $1.20 - $1.90 per unit |

| 25,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why This Box Design Delivers Superior Performance

- Regular Slotted Containers (RSCs): The automatic bottom eliminates taping of the box base, reducing assembly time by up to 60% compared to traditional RSCs

- Pure Tuck-style Boxes: The seal end provides significantly better security and tamper resistance than boxes that rely solely on friction-based tuck closures

- Rigid Boxes: Offers similar structural integrity and premium presentation at a fraction of the cost, with the added benefit of flat storage before assembly

Why Choose Haul Packaging for Your Auto Bottom Boxes?

- USA-Based Manufacturing Excellence: We understand the demands of American businesses and supply chains, ensuring reliable delivery and consistent quality

- Engineering-First Approach: We optimize every design for both performance and cost-efficiency, ensuring your boxes function flawlessly on packing lines

- Rapid Prototyping: We provide quick-turn prototypes to test assembly, fit, and function before you commit to full production

- Dedicated Customer Partnership: You'll work with a packaging expert who understands your business goals and helps you optimize your packaging strategy

Frequently Asked Questions (FAQ)

Q: How much faster is assembly compared to regular boxes?

A: The automatic bottom typically reduces base assembly time by 50-70% compared to taping Regular Slotted Containers. When combined with the consistent seal end closure, overall packing efficiency increases significantly.

Q: Can I get a sample to test on our packing line?

A: Absolutely! We strongly encourage ordering a seal end auto bottom box sample to evaluate assembly, structural integrity, and compatibility with your packing process. Contact us to arrange samples.

Q: Are these boxes suitable for automated packaging equipment?

A: Yes! This box style is specifically designed for compatibility with most automated packaging systems. The consistent dimensions and reliable automatic bottom mechanism make it ideal for high-speed operations.

Q: What types of seal do you recommend for the ends?

A: We can recommend the best sealing method based on your equipment and needs:

- Hot Melt Glue: Strong, fast-setting bonds ideal for automated equipment

- Cold Glue: Cost-effective option for manual application

- Pressure-Sensitive Tape: Quick and clean for lower-volume operations

Ready to Transform Your Packaging Efficiency with Haul Packaging?

Stop compromising between speed, security, and presentation. At Haul Packaging, Choose Seal End Auto Bottom Boxes to streamline your operations, protect your products, and project a professional brand image that builds customer trust and loyalty.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |