Custom Dispenser Boxes

We are a trusted Custom Dispenser Boxes Manufacturer and Supplier, providing comprehensive Wholesale solutions. Our expertise includes creating effective Custom Printed Dispenser Boxes that feature easy-dispense mechanisms and vibrant branding, making them ideal for food products, retail environments, and promotional displays that require both functionality and visual appeal.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Custom Dispenser Boxes | Countertop & Retail Display | Haul Packaging

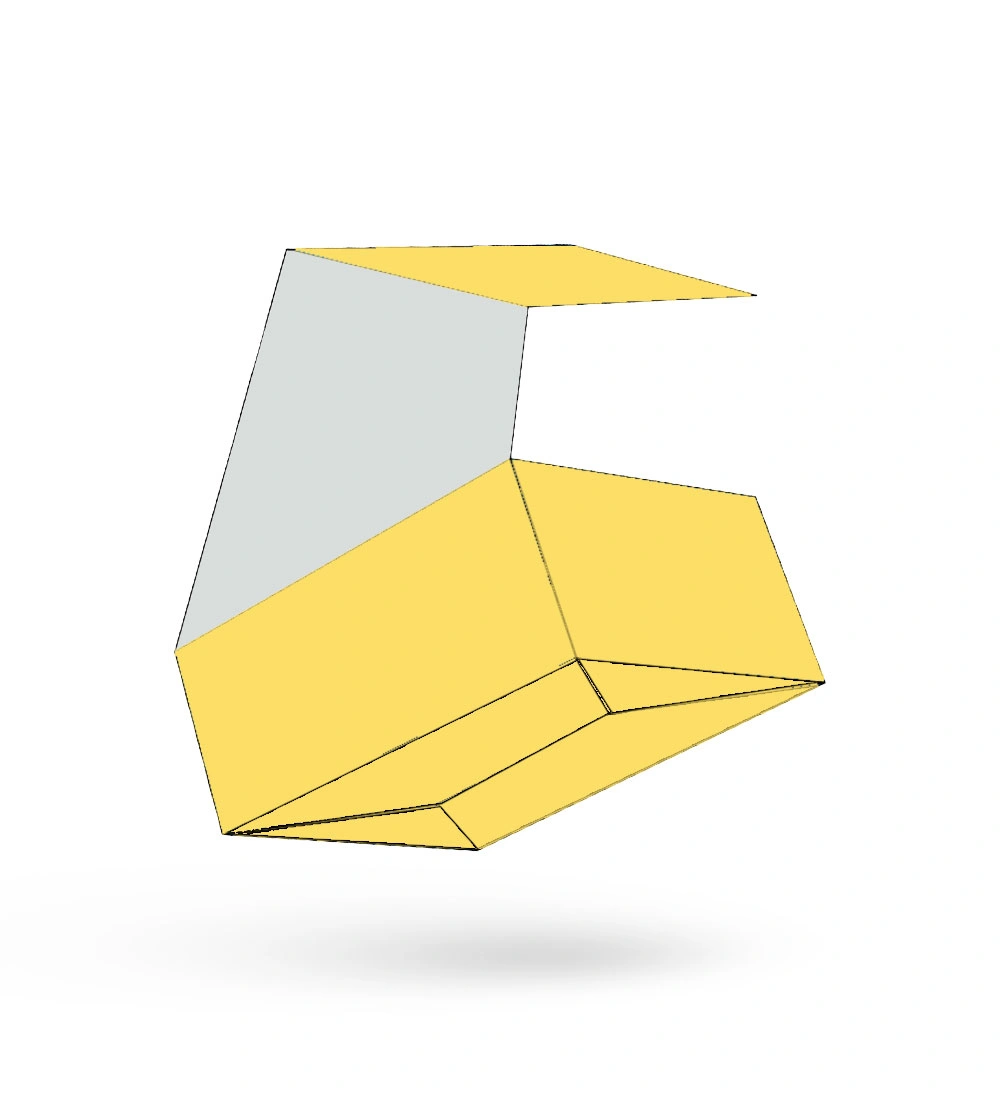

In environments where efficiency, hygiene, and space optimization are paramount, loose products create clutter, waste, and a poor customer experience. At Haul Packaging, we've engineered a smarter solution: Custom Dispenser Boxes. These innovative packaging systems are more than just containers; they are automated, organized, and highly visible point of purchase displays that streamline operations and amplify your brand.

Utilizing simple gravity feed technology, these boxes keep your products neatly presented and protected while ensuring they are always accessible. This comprehensive guide will explore how Custom Dispenser Boxes can transform your product management, the diverse industries they serve, the robust materials we use, and why they represent a critical tool for modern businesses across the United States.

Discover our versatile Custom Auto Bottom With Display Lid options perfect for showcasing products in retail environments with secure bases and visible lids for added presentation appeal.

What Are Custom Dispenser Boxes?

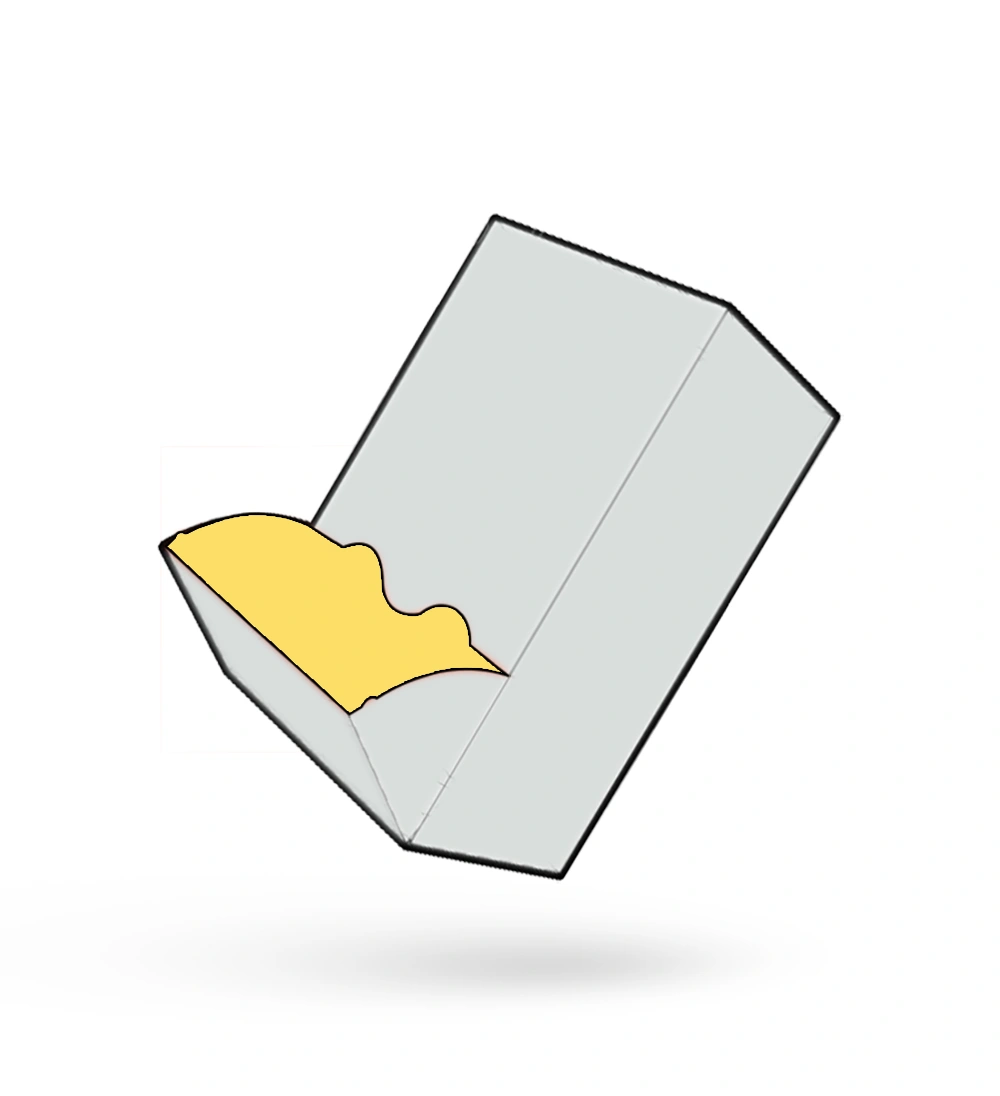

Custom Dispenser Boxes are a type of retail ready packaging specifically engineered for the organized storage and single-item dispensing of small products. They are designed to sit vertically on a countertop, shelf, or wall, using gravity to automatically bring the next item to the front as one is removed.

Key structural elements include:

- Gravity-Feed Design: Products are loaded into the top or back and slide gently forward as items are taken from the front.

- Dispensing Slot: A precisely sized opening at the front that allows one product to be removed at a time, preventing spillage and maintaining order.

- Easy-Load Mechanism: Many designs feature a hinged or tuck-top lid for simple refilling without disassembling the entire box.

- Sturdy Base: A wide, stable base prevents tipping, even when the box is nearly empty.

This functional design transforms messy piles of loose sachets and packets into a clean, professional, and highly efficient dispensing system.

Industries Served: Streamlining Operations Nationwide

The practical benefits of dispenser boxes make them invaluable across a wide range of sectors where small, individual items need to be managed efficiently.

| Industry | Primary Use Case | Key Benefit |

| Food Service & Hospitality | Organizing condiment packets, coffee creamers, sweeteners, tea bags, and sauce sachets in restaurants, cafes, and hotels. | Hygienic dispensing reduces touch points, keeps counters clean, and improves the speed of service during peak hours. |

| Healthcare & Pharmacy | Dispensing single-use OTC medication packets, condoms, alcohol swabs, and sample-sized products in clinics, hospitals, and pharmacy counters. | Promotes hygiene and provides discreet, controlled access to sensitive products. |

| Office & Workplace Management | Organizing sugar packets, creamers, stir sticks, and single-serve office supplies in breakrooms, reception areas, and coffee stations. | Reduces waste and clutter, creating a more professional and organized work environment. |

| Retail & Promotional Products | As a countertop display for small retail items like trading cards, lip balms, or as an organized sampling station for promotional products. | Increases product visibility and turns a functional necessity into a powerful branded packaging opportunity. |

| Salons & Spas | For single-use sample packets of creams, serums, and other treatment products, allowing clients to try before they buy. | Provides a clean, upscale way to present samples and encourages product trial. |

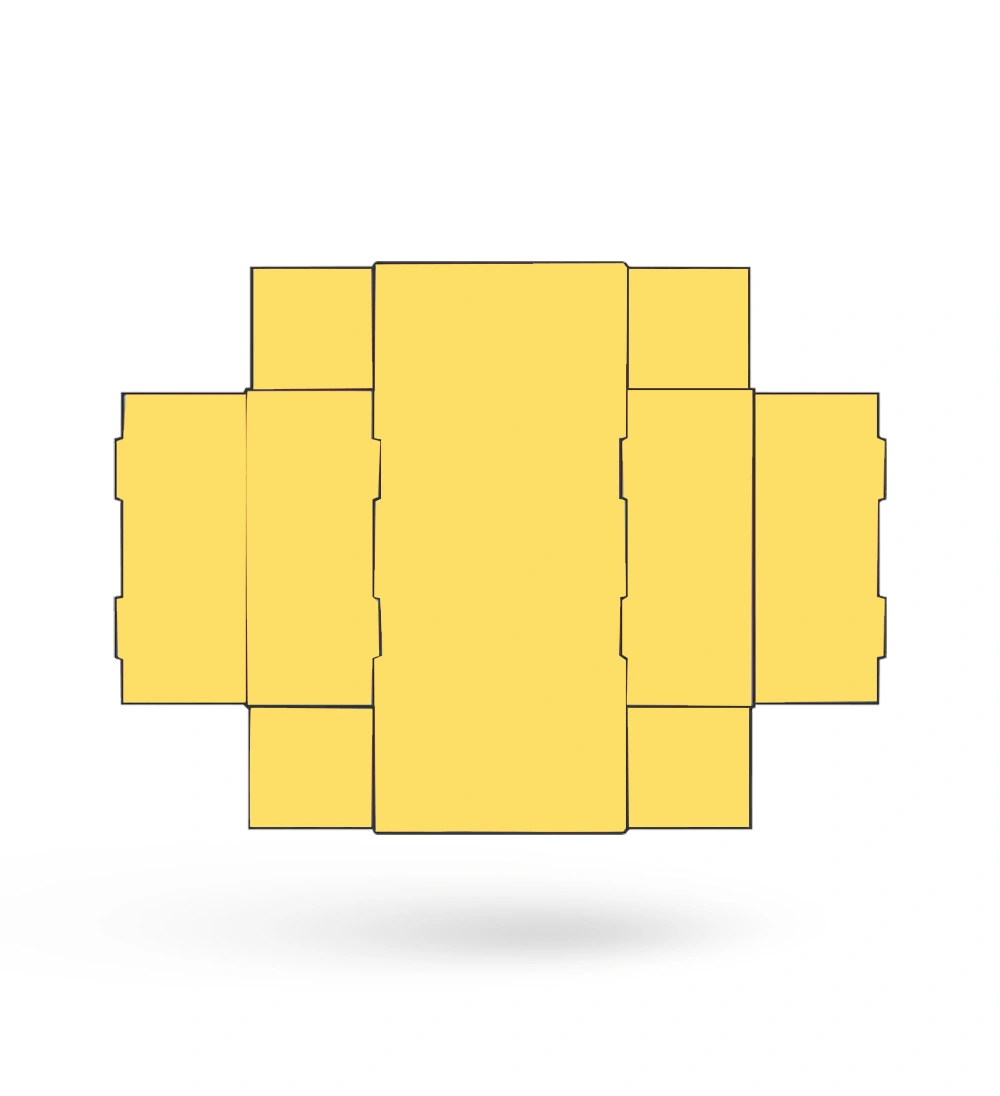

Materials & Construction: Built for Durability and Daily Use

Dispenser boxes face constant use and must be built to withstand the rigors of busy commercial environments. We use materials that are both durable and customizable.

-

Primary Materials:

-

- Corrugated Cardboard: The most popular and cost-effective choice.

- E-Flute: Thin and rigid, with excellent printing surface quality. Ideal for lighter products.

- B-Flute: Thicker, offering more cushioning and durability for heavier loads. The standard for shipping and heavier retail use.

- Solid Bleached Sulfate (SBS): A premium, bright white paperboard that offers a superior surface for high-impact graphics. Best for front-facing retail environments where aesthetics are crucial.

- Kraft Paperboard: Provides a natural, eco-friendly packaging look that appeals to brands emphasizing sustainability. Very durable.

- Corrugated Cardboard: The most popular and cost-effective choice.

-

Structural Integrity:

- Our boxes are engineered with interlocking panels and self-locking bottoms that require no tape for assembly, ensuring they remain sturdy during use.

- The dispensing slot is reinforced to prevent tearing, even with frequent use.

For superior strength and protection, explore our Custom Double Wall Tuck Front Boxes engineered to safeguard products while maintaining a polished retail look.

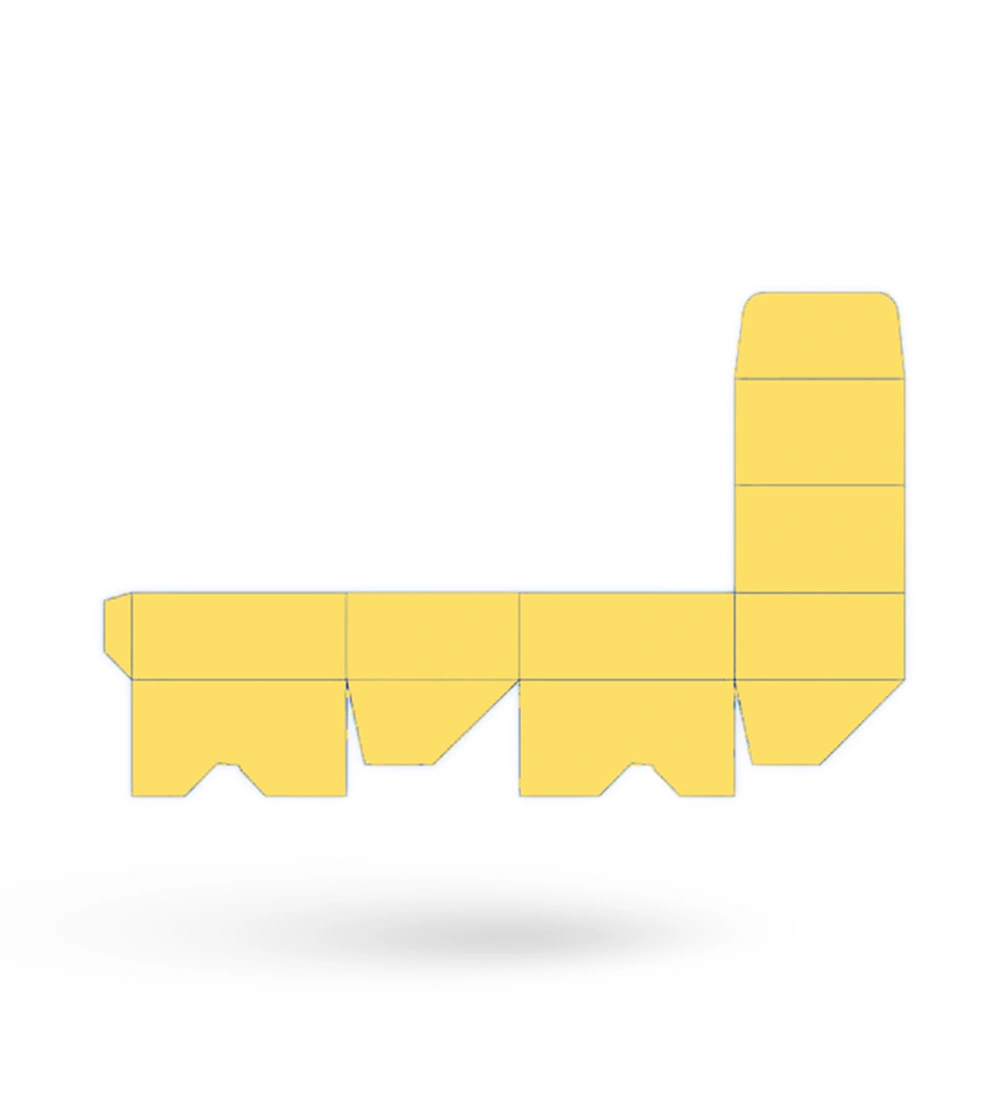

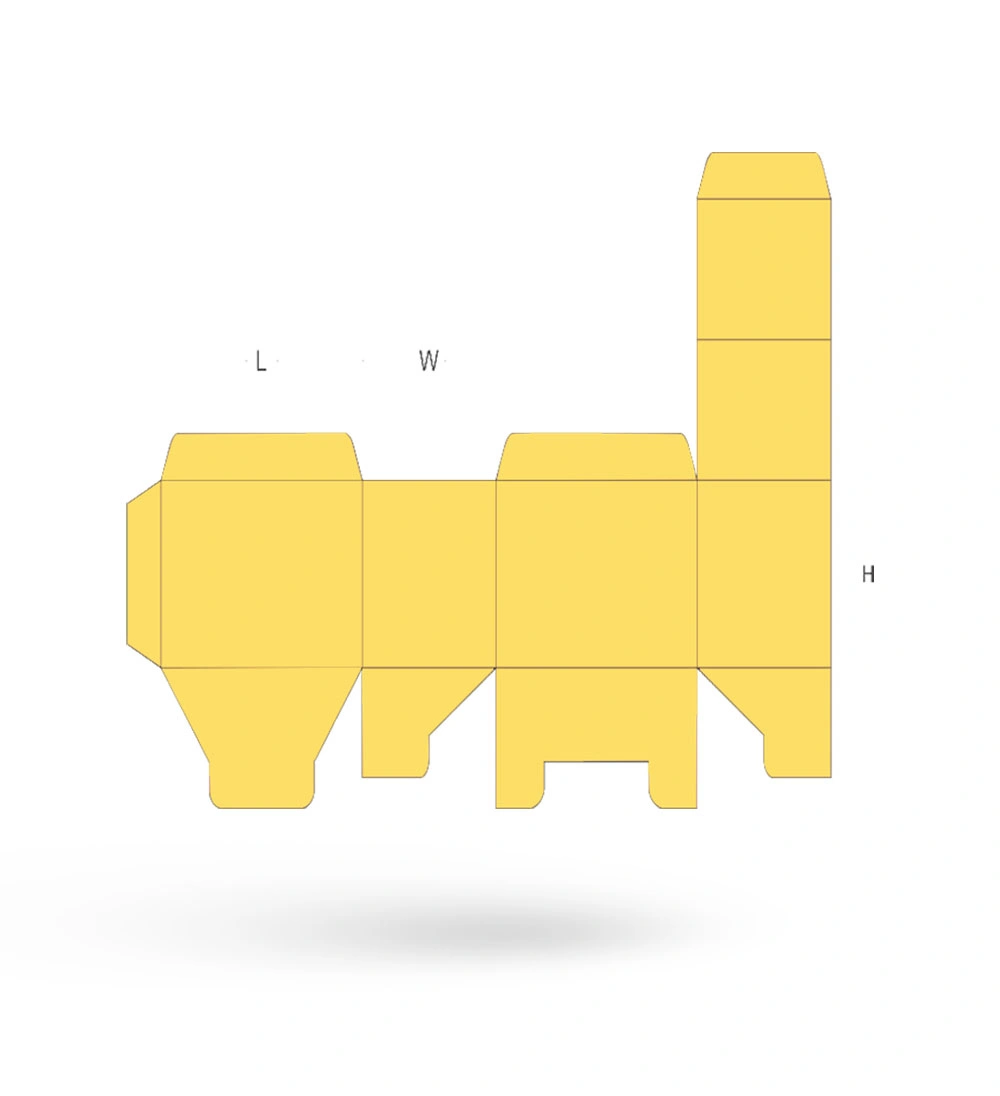

Sizes, Dimensions & Customization: Precision-Engineered for Your Product

An improperly sized dispenser box can lead to jamming or product damage. At Haul Packaging, we specialize in creating custom size boxes tailored to your product's exact dimensions.

- Fully Customizable Dimensions: We calculate the optimal internal dimensions based on your product's thickness, width, and length to ensure smooth, consistent dispensing.

- Dispensing Slot Precision: The size and shape of the slot are critical. It must be large enough for easy product removal but small enough to prevent multiple items from falling out. We prototype to ensure perfect functionality.

- Load Capacity: We can design boxes to hold anywhere from 25 to 200+ units, depending on your product and refill frequency needs.

Complete your packaging system with elegant Custom Envelopes ideal for inserts, samples, and promotional materials that accompany your dispenser displays.

Custom Printing & Finishing: Your Brand's Billboard on the Counter

A dispenser box occupies prime real estate on a countertop. This is a powerful marketing opportunity that should not be wasted.

-

Printing Processes:

- Direct-to-Corrugated Printing: Advanced digital printing that produces vibrant, full-color graphics directly onto the corrugated surface. Perfect for short to medium runs.

- Litho Lamination: For the highest quality custom printing, your design is printed on a separate sheet of SBS and then laminated to the corrugated board. This delivers photorealistic quality for high-impact graphics.

- Flexographic Printing: A cost-effective solution for larger runs with simpler designs and spot colors.

-

Branding Elements:

- Logo & Brand Colors: Prominently display your logo and use your brand's colors to ensure instant recognition.

- Call-to-Action (CTA): Use phrases like "Take One," "Try Me," or "Sample Here" to guide customer interaction.

- Product Information: List key features, ingredients, or usage instructions directly on the box.

Cost & Pricing: An Investment in Efficiency and Brand Visibility

The cost of your Custom Dispenser Boxes is an investment that pays for itself through reduced waste, improved efficiency, and constant brand exposure.

Key Factors Influencing Cost:

- Quantity: Bulk orders significantly reduce the per-unit cost due to setup and manufacturing efficiencies.

- Materials: The choice between corrugated cardboard, SBS, or Kraft paperboard affects the price.

- Printing: Basic one-color printing is economical, while full color printing and high-end litho lamination add cost and significant marketing value.

- Complexity: Standard rectangular designs are most cost-effective. Custom shapes or intricate internal structures may increase the price.

Sample Pricing Table (for estimation purposes only):

| Quantity | B-Flute Corrugated (2-Color Print) | E-Flute Corrugated (Full Color Direct Print) |

| 500 Units | ~ $2.50 - $3.75 per unit | ~ $3.50 - $5.00 per unit |

| 1,000 Units | ~ $1.75 - $2.75 per unit | ~ $2.50 - $3.75 per unit |

| 5,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why Dispenser Boxes Are an Operational Game-Changer

- Loose Products in Bins: Eliminates mess, reduces product waste from damage, and provides a much more professional and hygienic presentation.

- Bulk Boxes: Saves counter space and improves customer experience. Customers don't have to dig through a large box to find what they need.

- Plastic Dispensers: Offers a more sustainable, eco-friendly packaging solution that is fully customizable with your branding, unlike generic plastic units.

Why Choose Haul Packaging for Your Dispenser Boxes?

- USA-Based Expertise: We understand the needs of American businesses, from FDA compliance for food service to the specific demands of retail environments.

- Functional Design Focus: We engineer our boxes for real-world use, ensuring they dispense reliably, are easy to refill, and stand up to daily demands.

- Rapid Prototyping: We can quickly provide a working prototype to test with your specific products, guaranteeing perfect form and function before full production.

- Fast Turnaround: We know that operational efficiency is key. We offer some of the fastest production times in the industry to keep your business running smoothly.

Frequently Asked Questions (FAQ)

Q: Can your dispenser boxes handle different product shapes?

A: Absolutely. While ideal for flat packets and sachets, we can engineer boxes for a variety of shapes, from small tubes to rounded items. The key is precise dimensional design to ensure consistent gravity feed.

Q: How do you prevent products from jamming inside the box?

A: Jamming is prevented through precise engineering. We calculate the exact interior dimensions and the angle of the gravity feed tray to create smooth product flow. Testing with a prototype is a key part of our process.

Q: Are these boxes shipped flat?

A: Yes. All our Custom Dispenser Boxes are shipped and stored flat to minimize storage space and shipping costs. They feature easy, self-locking assembly that takes just seconds to set up.

Q: Can these boxes be wall-mounted?

A: Yes, many of our designs can be adapted for wall-mounting. We can incorporate hanging tabs or pre-punched holes into the design upon request.

Ready to Organize and Promote with Haul Packaging?

Stop letting clutter and inefficiency cost you time and money. Embrace the smart, professional solution of Haul Packaging’s Custom Dispenser Boxes. This is more than just packaging; it's a tool for better operations and a mobile billboard for your brand.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |