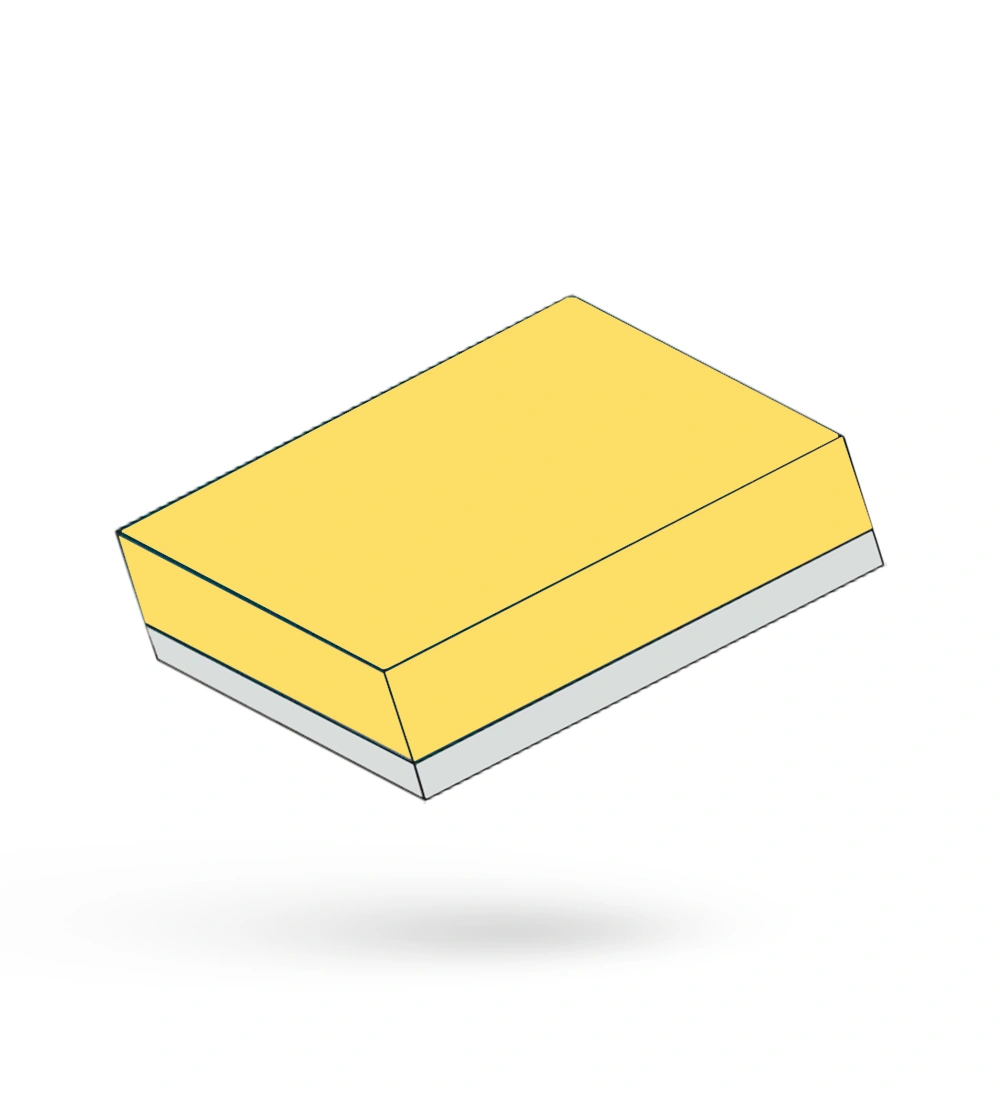

Custom Double Wall Tray Boxes

We are a trusted Custom Double Wall Tray Boxes Manufacturer and Supplier, providing comprehensive Wholesale solutions for durable packaging needs. Our expertise includes creating robust Custom Printed Double Wall Tray Boxes that feature reinforced walls and vibrant branding, making them ideal for heavy products, automotive parts, and high-value items that require exceptional protection and professional presentation.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

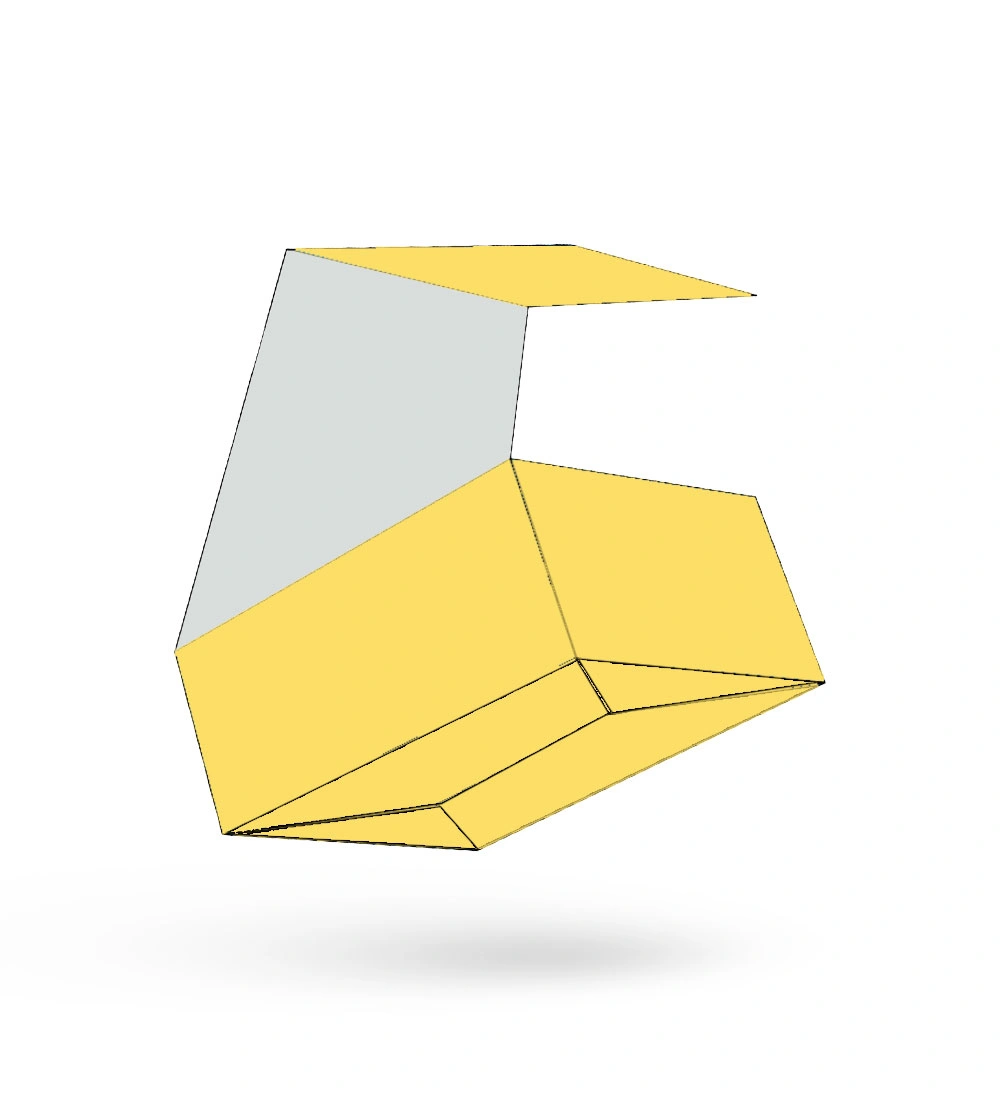

Custom Double Wall Tray Boxes | Heavy-Duty Packaging Solutions | Haul Packaging

In the world of packaging, not all products are created equal. Heavy, fragile, or high-value items demand a level of protection that standard packaging simply cannot provide. At Haul Packaging, we engineer solutions for these demanding applications with our Custom Double Wall Tray Boxes. This isn't just packaging; it's a protective fortress for your products, combining industrial-strength durability with clean, accessible presentation.

Constructed from double wall corrugated board, these heavy-duty tray boxes are designed to withstand the rigors of modern supply chains, from manufacturing and distribution to e-commerce shipping and retail display. This comprehensive guide will explore the engineering behind these robust boxes, their vast applications across industries, and how they can solve your most challenging packaging problems.

To explore other strong and reliable designs, check out our Custom Auto Bottom With Display Lid for equally durable and visually appealing packaging options.

What Are Double Wall Tray Boxes?

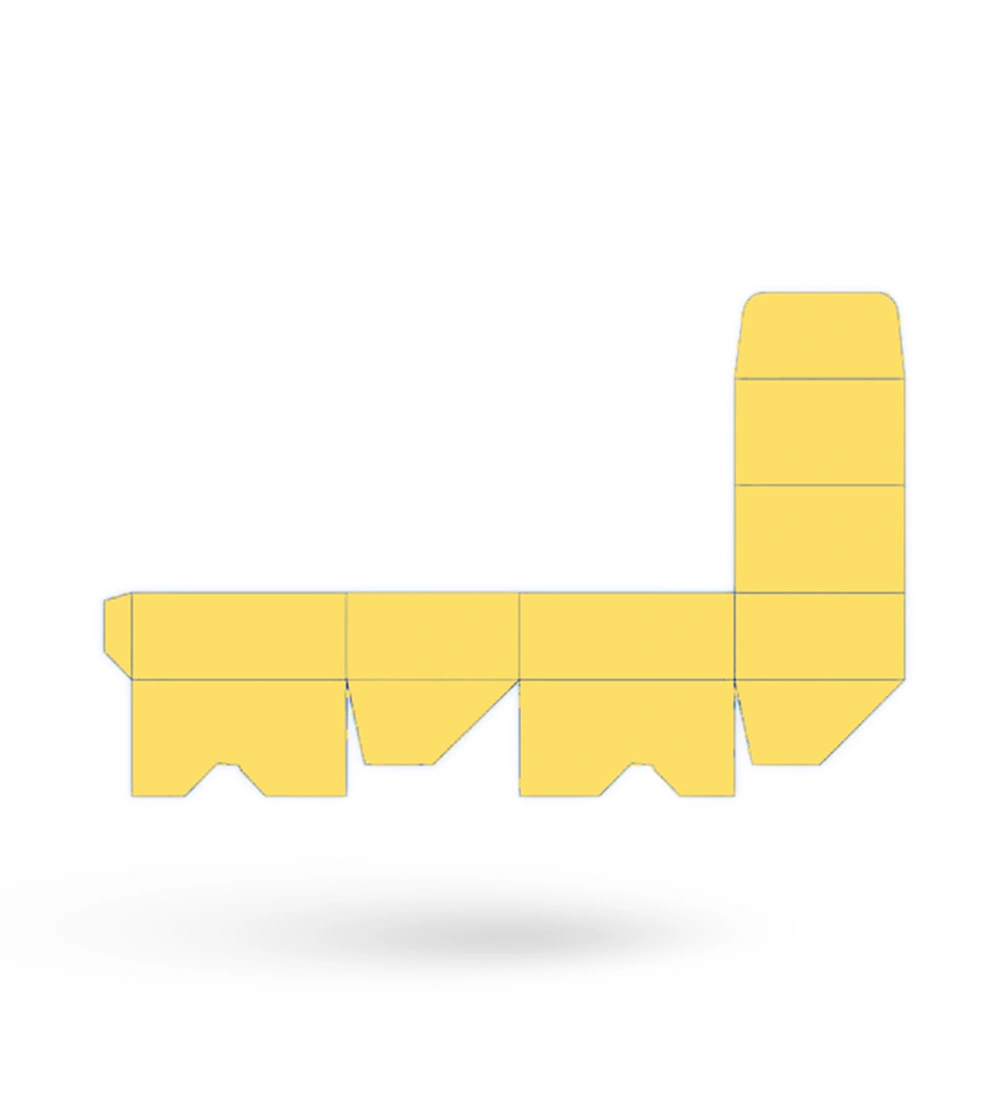

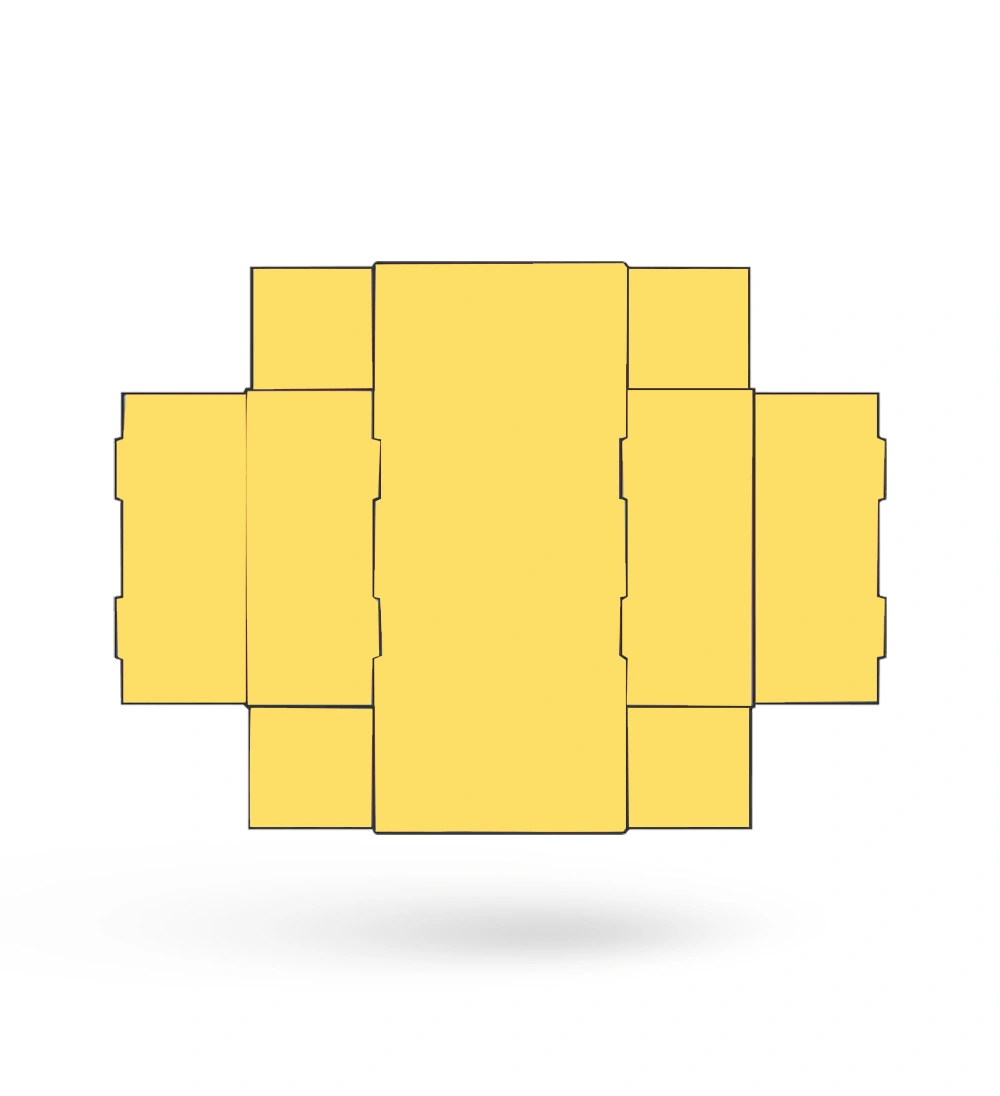

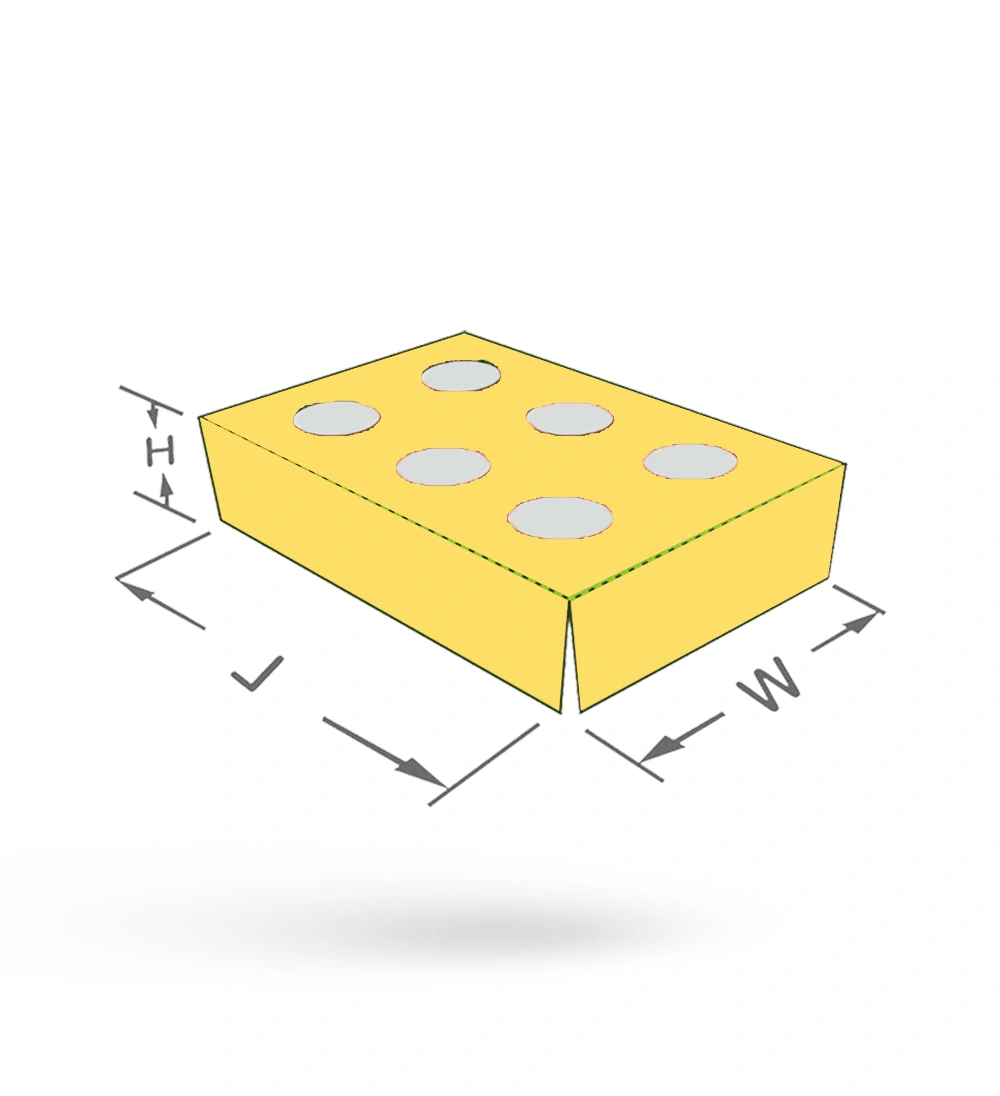

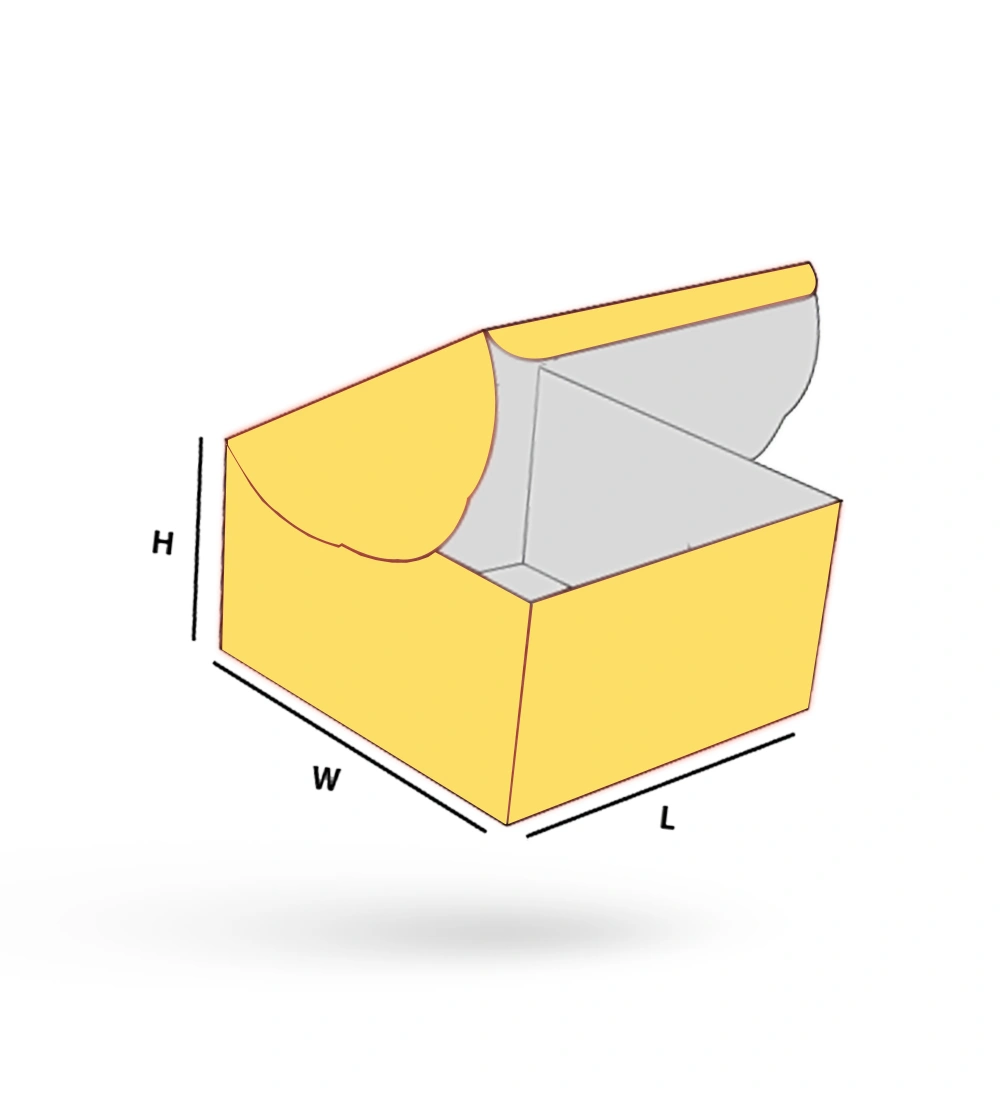

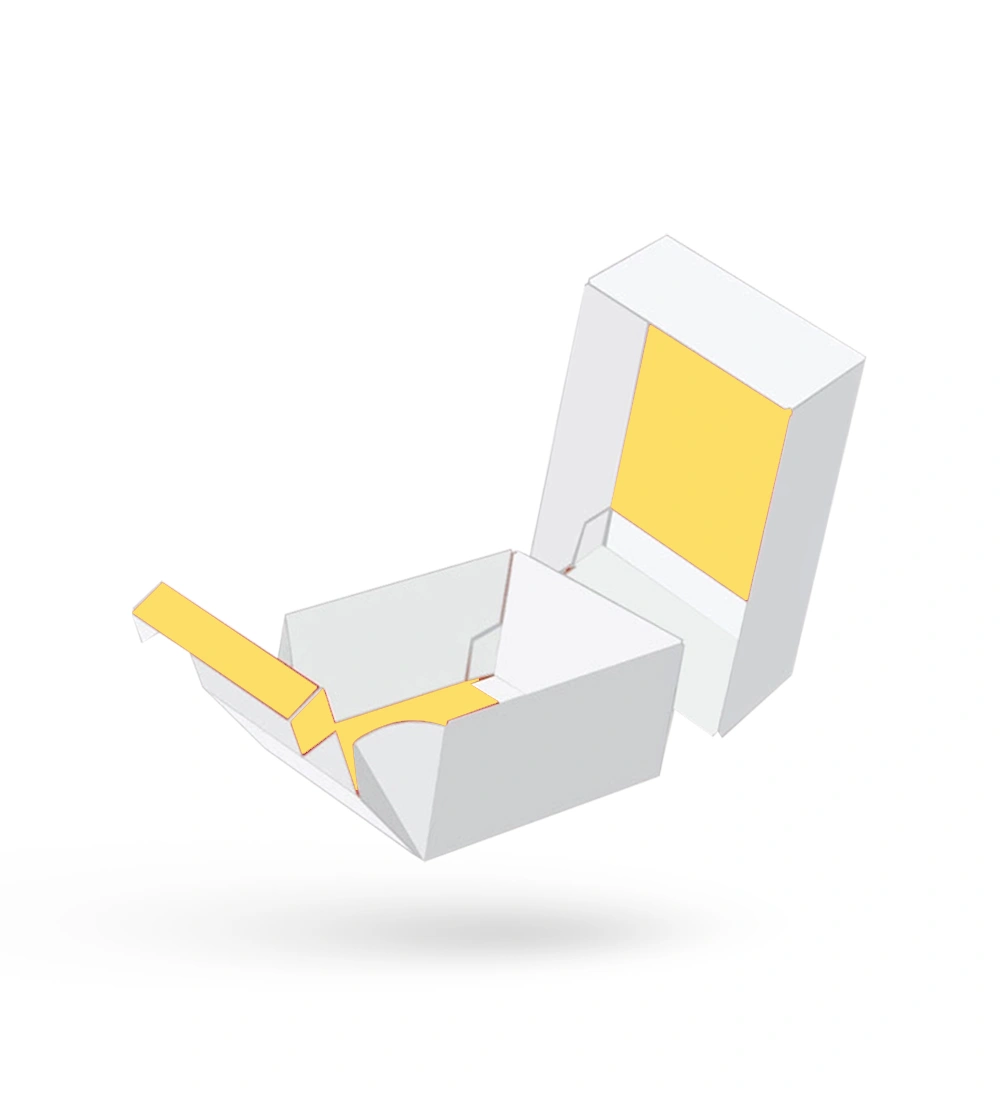

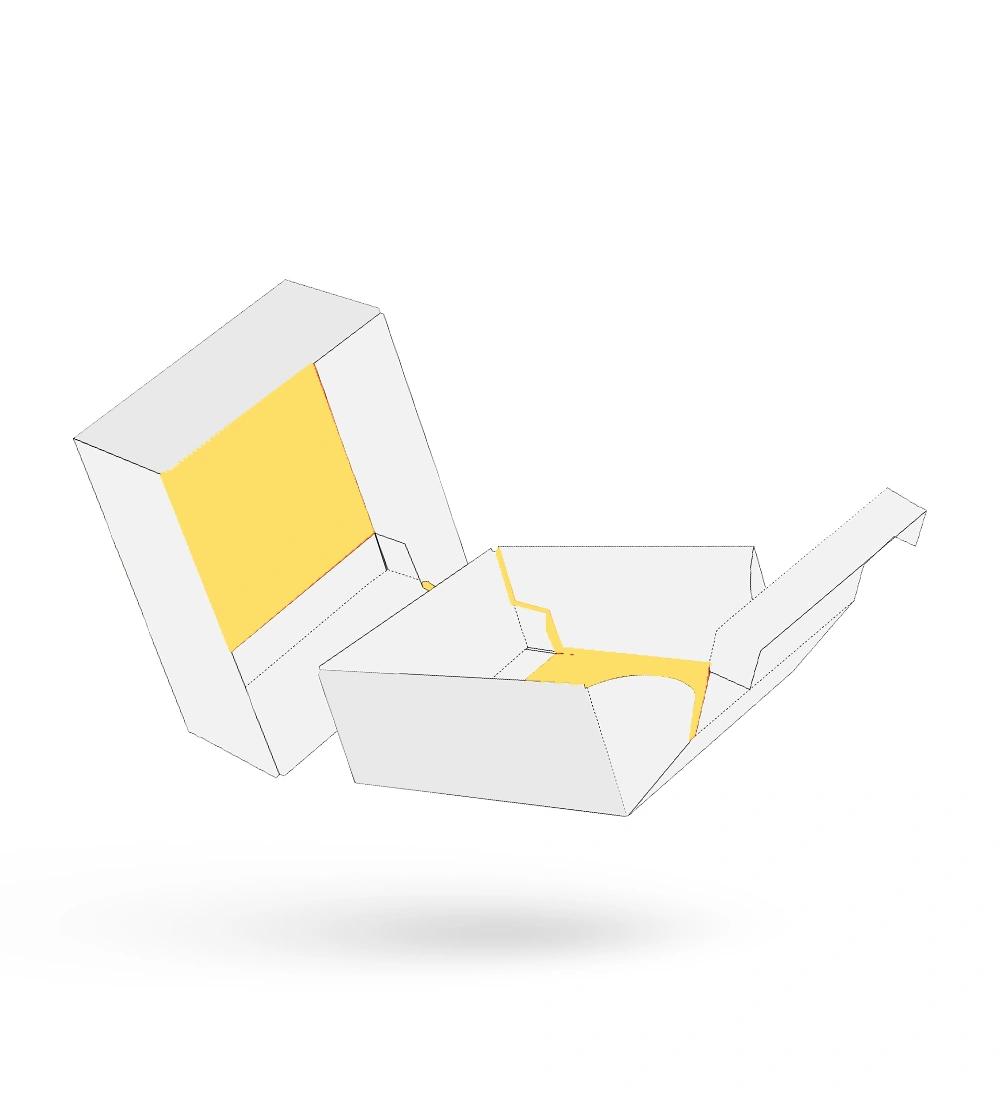

Custom Double Wall Tray Boxes are a type of rigid, setup box known for their exceptional strength and simple, effective design. Unlike a traditional folding carton with a separate lid, a tray box features an open-top design with sturdy, vertical walls.

The key to their performance lies in the construction:

- Double Wall Construction: The board consists of three liners and two fluted layers bonded together. This creates an incredibly rigid, impact-resistant material that is far stronger than single-wall corrugated.

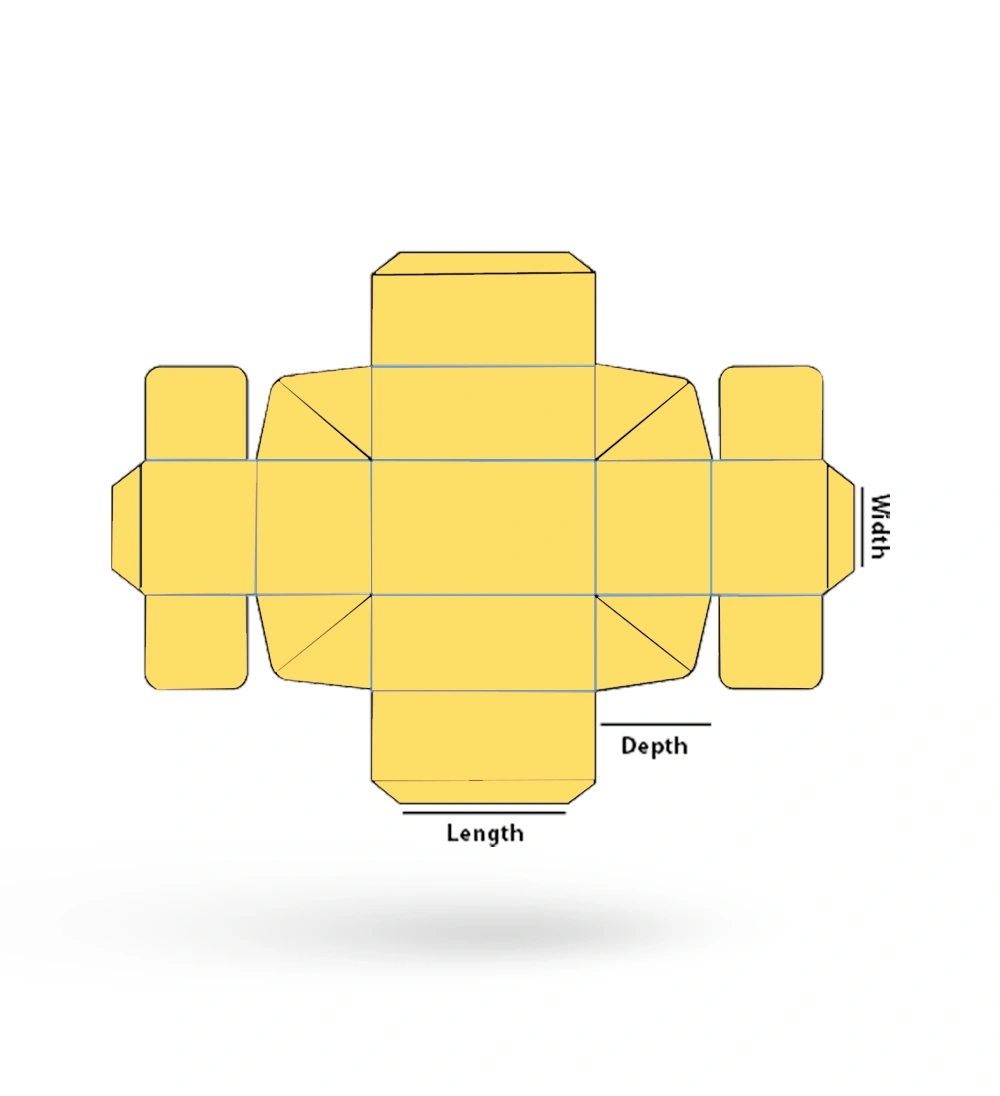

- Tray-Style Design: The box is formed from a single piece of die-cut board that is folded upwards to create solid walls, resulting in a stable, stackable platform for your products.

This combination of heavy-duty construction and accessible design makes them ideal for both protective shipping and elegant display.

Industries Served: Built for Demanding Applications

The unparalleled strength of double wall trays makes them indispensable across a wide range of sectors where product integrity is non-negotiable.

| Industry | Primary Use Case | Key Benefit |

| Industrial & Manufacturing | Packaging for machinery parts, tools, and raw materials. | The load-bearing capacity prevents box failure under extreme weight, protecting both the product and personnel during handling. |

| Electronics & Technology | Housing for computers, servers, audio/video equipment, and sensitive instruments. | Provides crucial protection against crushing and impacts that can damage sensitive circuitry and components. |

| Automotive & Aerospace | Shipping for engine components, transmission parts, and other high-value mechanical items. | The rigid structure prevents in-transit damage that could lead to costly returns and warranty claims. |

| E-commerce & Retail | For heavy product packaging like fitness equipment, home goods, and multi-pack items sold online. | Survives the "last-mile" delivery gauntlet while presenting a premium unboxing experience. |

| Food & Beverage | For gourmet gift baskets, glass bottle shipments, and bulk food items. | The stackable design maximizes warehouse and truck space while protecting fragile contents. |

Materials & Construction: The Anatomy of Strength

The performance of a Double Wall Tray Box is a direct result of its material science. We use premium components to ensure consistent, reliable performance.

-

Flute Profiles (The Core of Strength):

- BC Flute: The most common and versatile double wall combination. 'B' flute provides excellent puncture resistance and a flat surface for printing, while 'C' flute offers superior cushioning and stacking strength. This is our workhorse for most heavy-duty applications.

- EB Flute: A premium combination where 'E' flute provides a super-smooth surface for high-quality printing, and 'B' flute adds the necessary rigidity and crush resistance.

-

Liner Grades:

- Kraft Liner: The standard, high-strength brown outer surface. Offers excellent durability and is naturally eco-friendly.

- White-Top Liner: A bright white surface that provides a superior, clean canvas for high-impact graphics and vibrant brand printing.

-

Structural Engineering:

- Reinforced Corners: Our trays are designed with interlocking glue joints or stitched corners that prevent bulging and maintain structural integrity.

- Uniform Wall Depth: Consistent wall height ensures even weight distribution and stable stacking.

If you need another sturdy corrugated solution, consider our Custom Double Wall Tuck Front Boxes combining protection with a refined closure system.

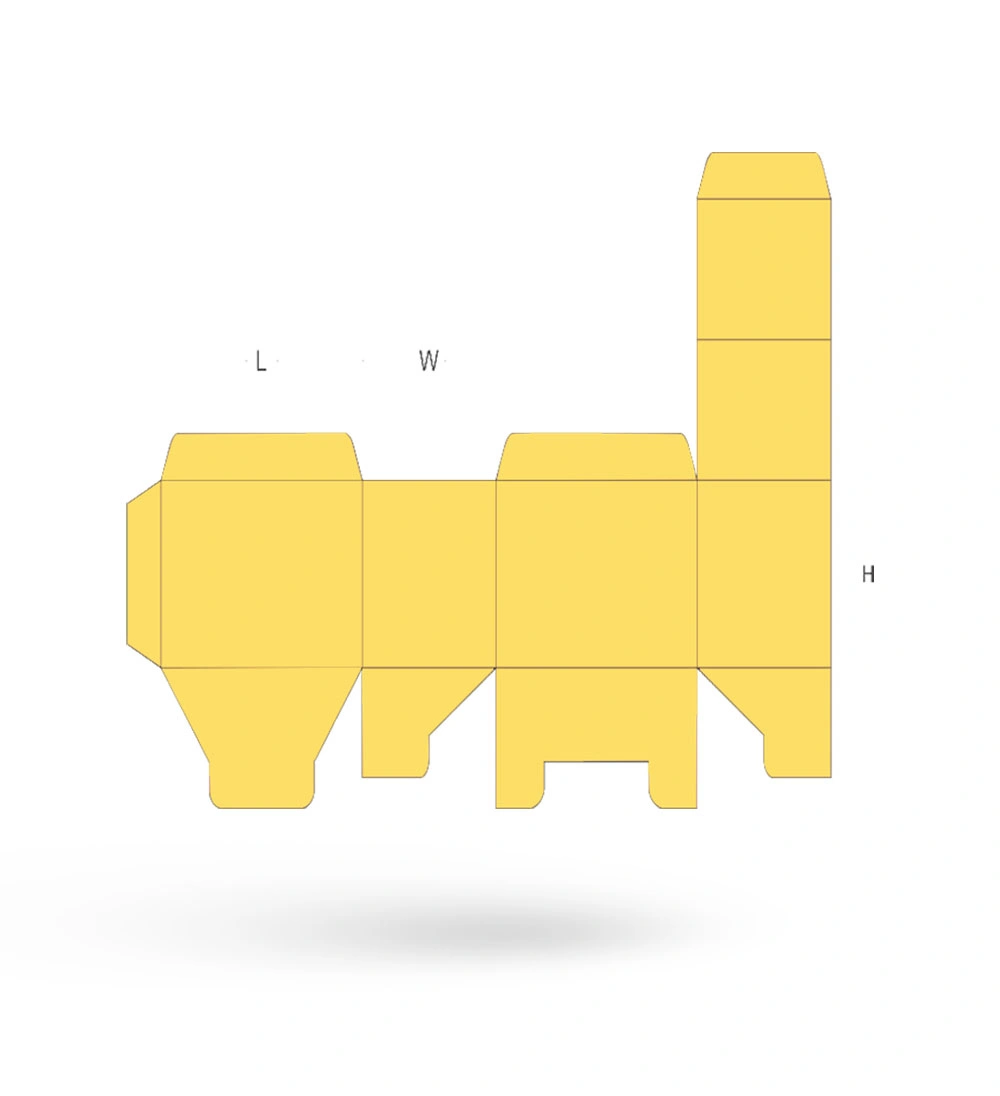

Sizes, Dimensions & Customization: Precision-Engineered for Your Product

A one-size-fits-all approach compromises protection. At Haul Packaging, we specialize in creating truly custom size trays that fit your product like a glove.

- Fully Customizable Dimensions: We manufacture to your exact internal length, width, and depth requirements. A precise fit minimizes internal product movement, which is a primary cause of in-transit damage.

- Load Capacity Calculations: Our design team can engineer trays based on your product's specific weight and dimensions to ensure the box's load-bearing capacity far exceeds your requirements.

- Accessory Integration: We can design trays to incorporate custom inserts, foam cushions, dividers, or platforms to hold multiple items securely in place.

You can also enhance your packaging experience with personalized options such as our Custom Envelopes, ideal for branded documentation, inserts, or elegant product add-ons.

Custom Printing & Finishing: Brand Your Fortress

Despite their industrial strength, these trays offer excellent opportunities for branding. The large, flat surfaces are ideal for making a powerful visual statement.

-

Printing Processes:

- Direct-to-Corrugated Printing: Advanced digital and flexographic printing that applies high-impact graphics directly onto the board. Ideal for short to medium runs with vibrant colors.

- Litho Lamination: For the ultimate in print quality, your design is printed on a separate sheet of paper and then laminated to the corrugated tray. This process delivers photorealistic quality for premium retail packaging.

-

Branding Applications:

- Logo & Brand Messaging: Prominently display your logo and value propositions directly on the packaging.

- Instructional Printing: Print handling instructions, "Fragile" warnings, or assembly diagrams directly on the box.

- Retail-Ready Graphics: For trays going directly to store shelves, we can print UPC codes, product features, and marketing copy.

Cost & Pricing: Investing in Damage Prevention

The cost of a Custom Double Wall Tray Box is an investment in minimizing product loss, reducing shipping damage claims, and enhancing your brand's reputation for quality.

Key Factors Influencing Cost:

- Quantity: Bulk orders dramatically reduce the per-unit cost due to material and setup efficiencies.

- Material: The choice of flute combination (BC vs. EB) and liner grade (Kraft vs. White-Top) affects the price.

- Size: Larger trays require more material and may require heavier flute profiles to maintain rigidity.

- Printing: Basic one-color printing is economical, while full color printing and litho lamination add cost but significant marketing value.

Sample Pricing Table (for estimation purposes only):

| Quantity | BC Flute Kraft (1-2 Color Print) | EB Flute White-Top (Full Color Direct Print) |

| 500 Units | ~ $4.50 - $7.00 per unit | ~ $6.50 - $9.50 per unit |

| 1,000 Units | ~ $3.25 - $5.50 per unit | ~ $5.00 - $7.75 per unit |

| 5,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why Double Wall Trays Are a Supply Chain Game-Changer

- Single-Wall Boxes: Offers 2-3 times the stacking strength and puncture resistance, dramatically reducing the risk of crushing in warehouse and shipping environments.

- Wooden Crates: Provides similar protection at a fraction of the weight and cost, while being easier to assemble and more environmentally friendly.

- Standard RSCs (Regular Slotted Cartons): The rigid tray design prevents bulging and maintains its shape under stress, unlike RSCs which can deform and compromise product safety.

Why Choose Haul Packaging for Your Heavy-Duty Trays?

- USA-Based Manufacturing & Expertise: We understand the demands of American supply chains and can ensure your packaging meets all necessary standards for durability and logistics.

- Engineering-First Approach: We don't just sell boxes; we analyze your product's needs and engineer a solution that guarantees protection.

- Quality Assurance: Every batch of our double wall corrugated is tested for edge crush strength (ECT) and burst strength to ensure it meets our rigorous standards.

- End-to-End Service: From initial design and prototyping to printing and delivery, we manage the entire process, making it seamless for you.

Frequently Asked Questions (FAQ)

Q: What is the maximum weight your double wall trays can hold?

A: The load-bearing capacity depends on the flute combination and box dimensions. Our standard BC-flute trays can typically handle 80-150 lbs of static weight, and even more when the weight is evenly distributed. We can engineer solutions for specific weight requirements.

Q: Can I get a sample to test before placing a full order?

A: Absolutely. We strongly encourage ordering a tray box sample to perform your own stress tests, check the fit for your product, and evaluate the print quality. Contact us to arrange a sample kit.

Q: Are these boxes shipped flat or assembled?

A: They are shipped flat to minimize storage space and shipping costs. They are designed for quick and easy setup—simply fold the four walls upright and secure the corners.

Q: Can these trays be used for international shipping?

A: Yes, the robust double wall construction is ideal for the handling demands of international logistics. We can ensure the materials comply with ISPM 15 standards for international wood packaging if required.

Ready to Fortify Your Products with Haul Packaging?

Stop accepting packaging failures as a cost of doing business. At Haul Packaging, Upgrade to the proven protection of Custom Double Wall Tray Boxes. This is an investment in your product's safe arrival, your customer's satisfaction, and your brand's integrity.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |