Custom Double Wall Tuck Front Boxes

We are a trusted Custom Double Wall Tuck Front Boxes Manufacturer and Supplier, providing comprehensive Wholesale solutions for secure packaging. Our expertise includes creating robust Custom Printed Double Wall Tuck Front Boxes that feature reinforced walls and a secure tuck front, making them ideal for heavy products, subscription boxes, and retail items that require superior protection during shipping and handling.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Custom Double Wall Tuck Front Boxes | Secure & Durable Packaging | Haul Packaging

In the competitive landscape of modern commerce, packaging must perform a delicate balancing act. It needs to be rugged enough to survive the rigors of shipping, yet convenient and elegant enough to enhance the customer experience. At Haul Packaging, we've engineered the solution: Custom Double Wall Tuck Front Boxes. This innovative packaging style merges the industrial strength of double wall corrugated with the user-friendly simplicity of a tuck tab closure, creating a versatile solution for brands that refuse to compromise on protection or presentation.

Whether you're shipping monthly subscriptions, fulfilling e-commerce orders, or packaging products for retail shelves, these boxes deliver unparalleled performance. This comprehensive guide will explore the unique benefits, structural advantages, and vast applications of this powerhouse packaging solution.

For even more versatility in strength and display design, explore our Custom Auto Bottom With Display Lid, perfect for showcasing products while ensuring a secure base.

What Are Double Wall Tuck Front Boxes?

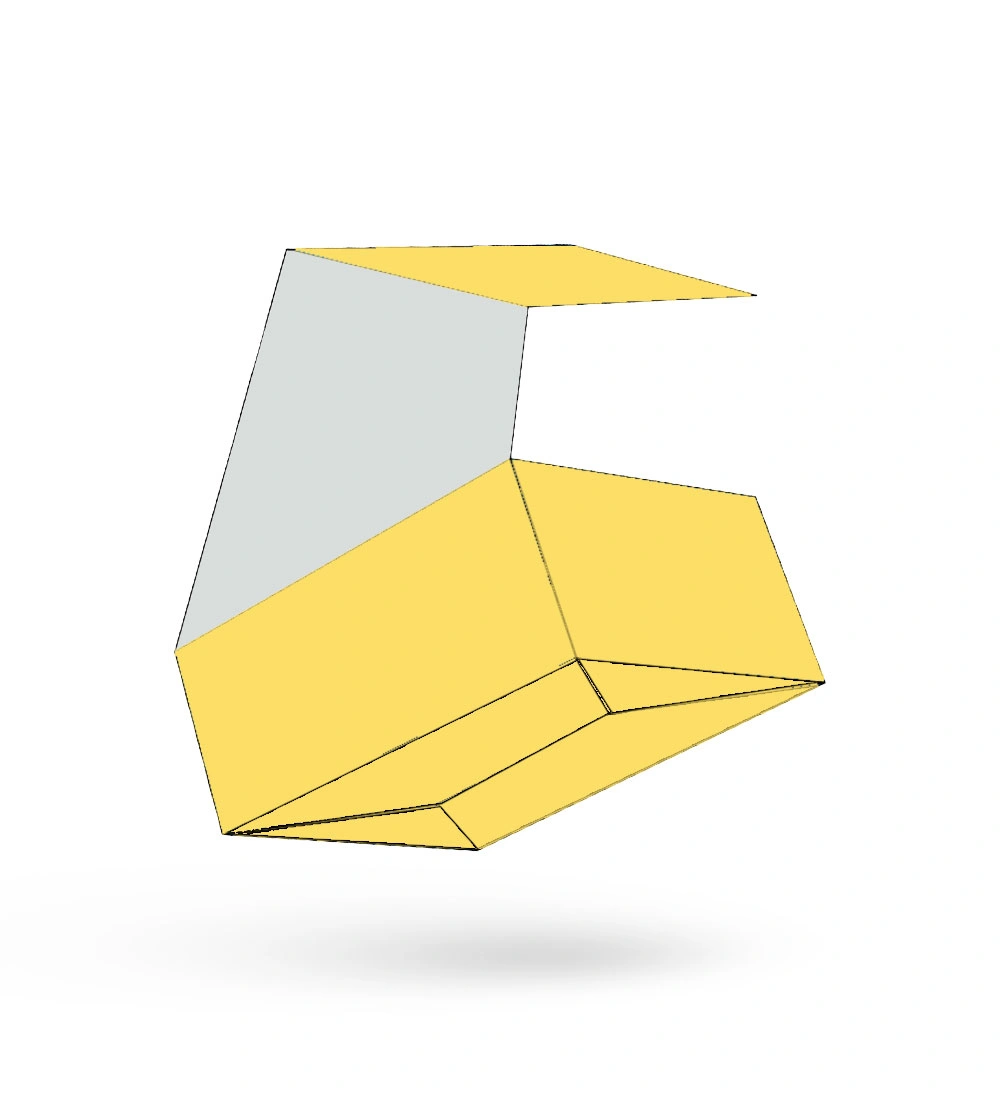

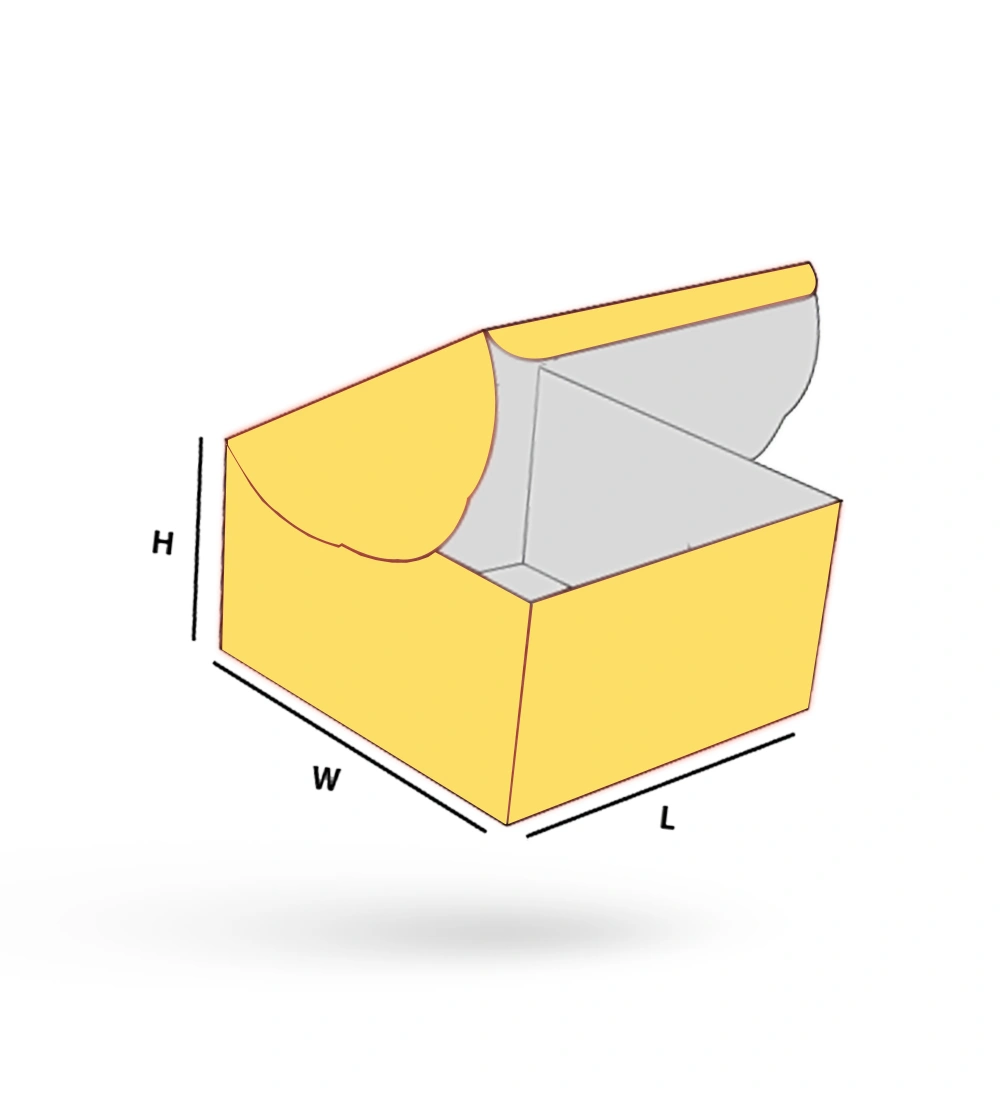

Custom Double Wall Tuck Front Boxes are a premium packaging format defined by two key characteristics: their material construction and their closure mechanism.

- Double Wall Construction: The box is made from double wall corrugated board, which consists of three linerboards and two fluted mediums layered together. This creates a remarkably rigid and durable material that offers significantly higher crush resistance and stacking strength than single-wall alternatives.

- Tuck Front Closure: Instead of using tape or glue, the box features a secure tuck tab closure where the front panel(s) of the lid are designed to tuck neatly into the front panel of the base, locking the box shut. Many designs also feature an auto-bottom for quick, tape-free assembly of the base.

The result is a box that is both incredibly strong and remarkably easy for both the packer and the end-customer to use.

Industries Served: The Workhorse of Modern Packaging

The unique combination of strength and convenience makes these boxes exceptionally versatile, serving a wide array of industries.

| Industry | Primary Use Case | Key Benefit |

| Subscription Box Services | The primary container for monthly curated boxes in beauty, lifestyle, food, and hobby niches. | The secure closure protects contents during shipping, while the easy-open design enhances the unboxing experience. The reusable nature adds value. |

| E-commerce & DTC Brands | Shipping everything from fragile home goods and gadgets to apparel and books. | The double wall construction drastically reduces damage rates, while the professional look elevates brand perception. |

| Retail & Boutique | Packaging for products that will be shipped to stores and then displayed directly on the shelf. | Serves as both a shipping container and retail-ready packaging, eliminating the need for repackaging. |

| Food & Beverage | For gourmet food sets, specialty coffee, tea, and confectionery that require sturdy, presentable packaging. | Protects fragile contents from crushing and provides a clean, professional look for gifting. |

| Industrial & Manufacturing | For heavier components, tools, and parts that need more protection than a standard box can offer. | The heavy-duty construction prevents box failure, while the tuck closure allows for easy inspection and resealing. |

Materials & Construction: Engineered for Performance

The exceptional performance of these boxes stems from a deliberate choice of materials and structural design.

-

Corrugated Flute Profiles:

- BC Flute: The most common and balanced double wall combination. The 'B' flute provides a flat surface excellent for printing and good puncture resistance, while the 'C' flute offers superior cushioning and vertical compression strength. This is our recommended choice for most applications.

- EB Flute: A premium option where the outer 'E' flute provides an ultra-smooth surface for high-quality printing, and the 'B' flute adds the necessary rigidity. Ideal for luxury products where first impression is critical.

-

Liner Options:

- Natural Kraft: The standard, high-strength brown surface. Cost-effective and naturally eco-friendly.

- White-Top Liner: A bright white, clay-coated surface that provides a superior, pristine canvas for high-impact graphics and vibrant brand printing.

-

Closure Engineering:

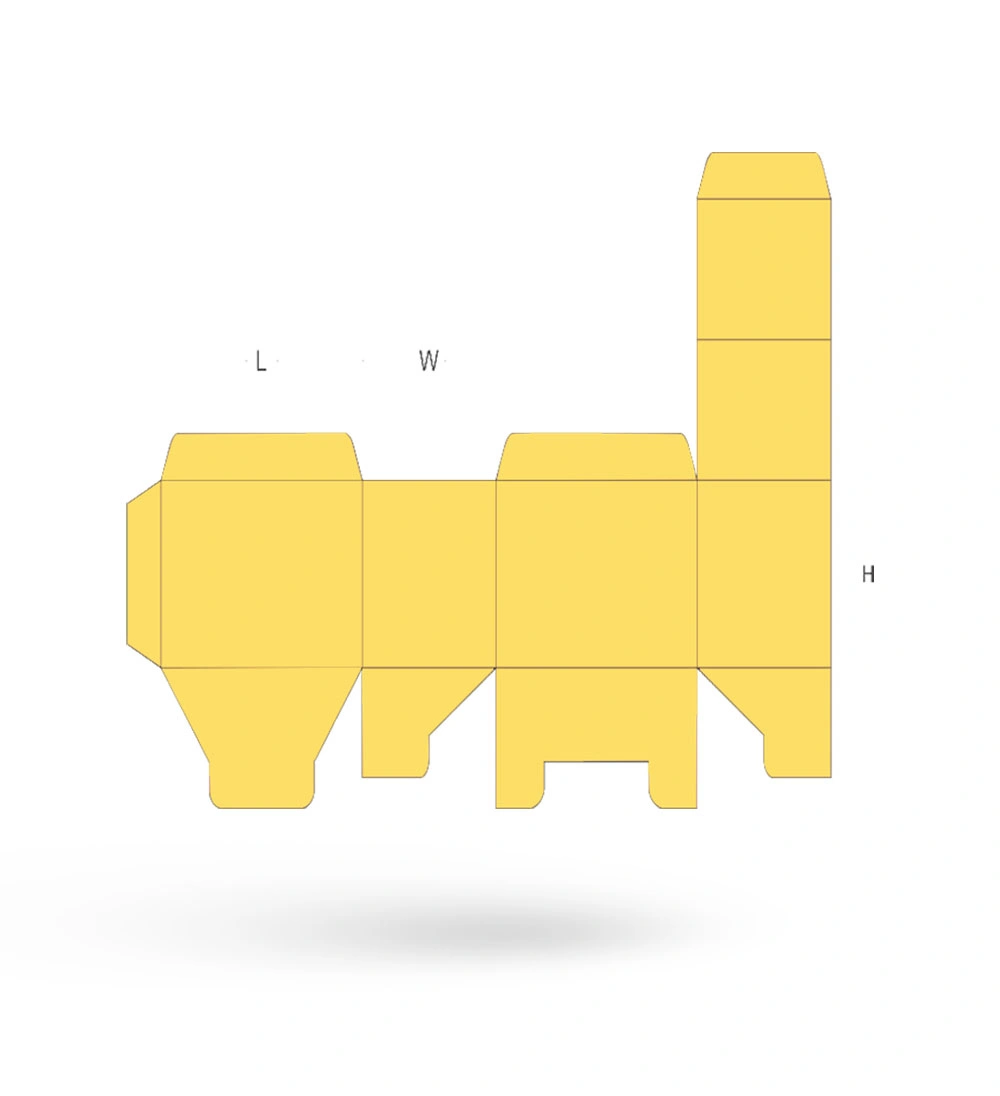

- The tuck tab is precisely die-cut to ensure a snug, secure fit that won't pop open during transit but is still easy for customers to open.

- The auto-bottom design uses a series of interlocking folds to create a solid, flat base that locks into place without tape, speeding up the packing process.

If your packaging demands even greater rigidity and open-top accessibility, check out our Custom Double Wall Tray Boxes engineered for heavy-duty protection with premium presentation.

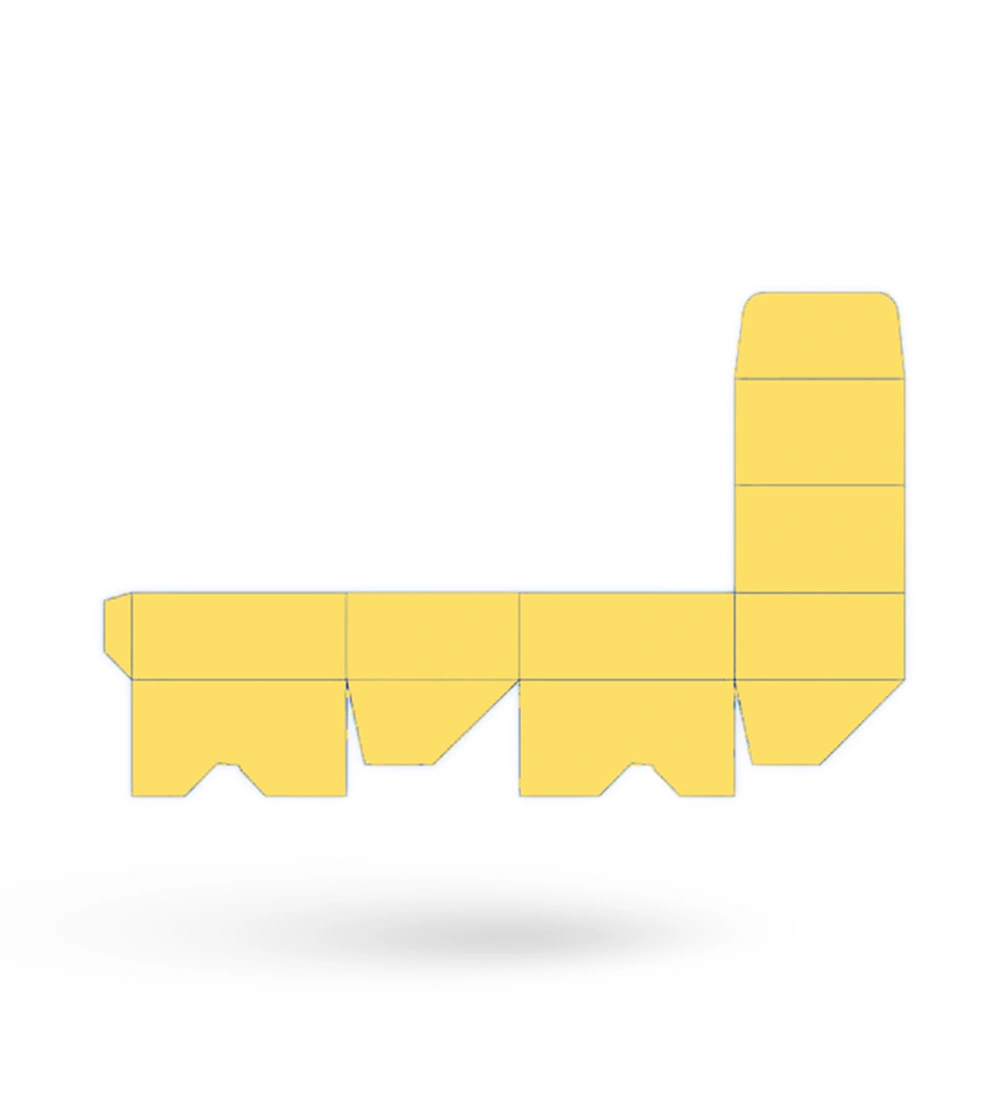

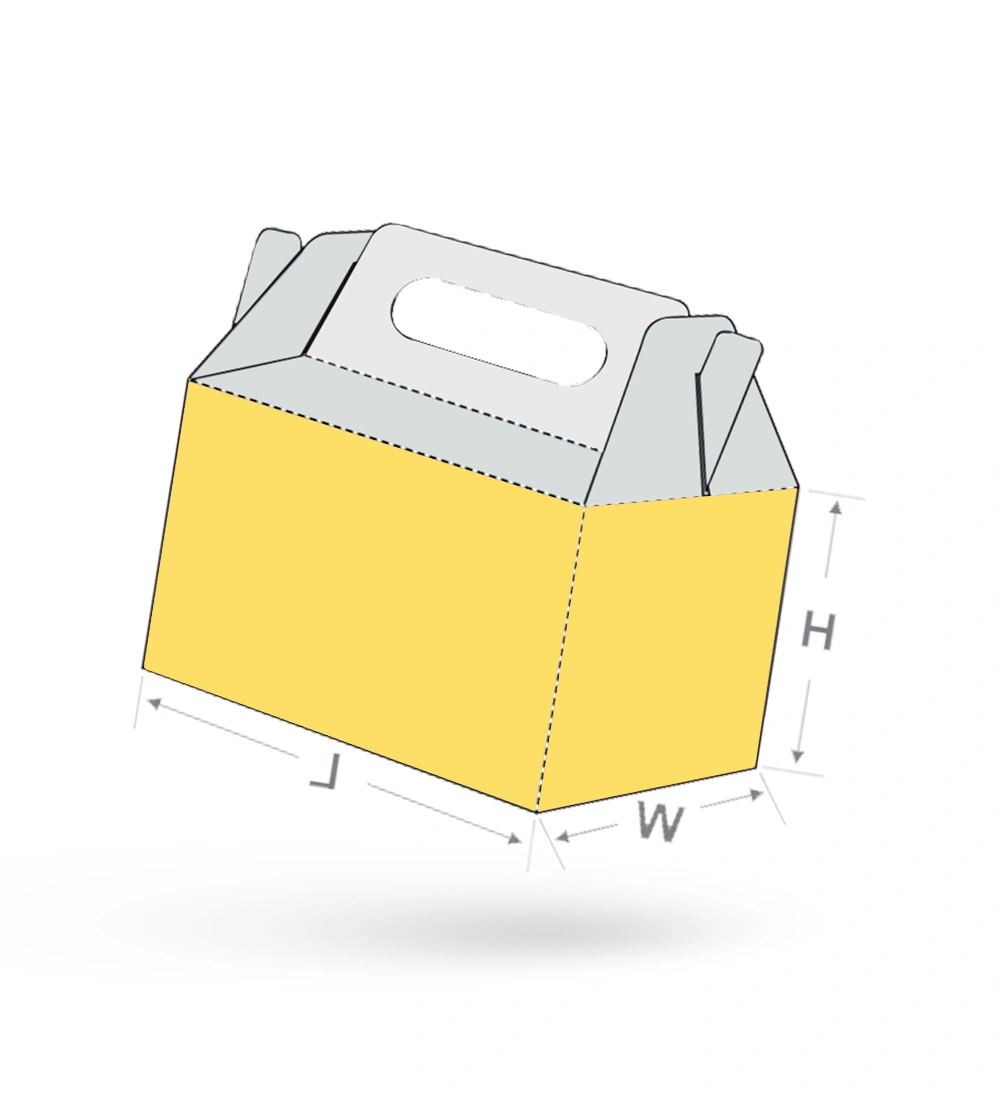

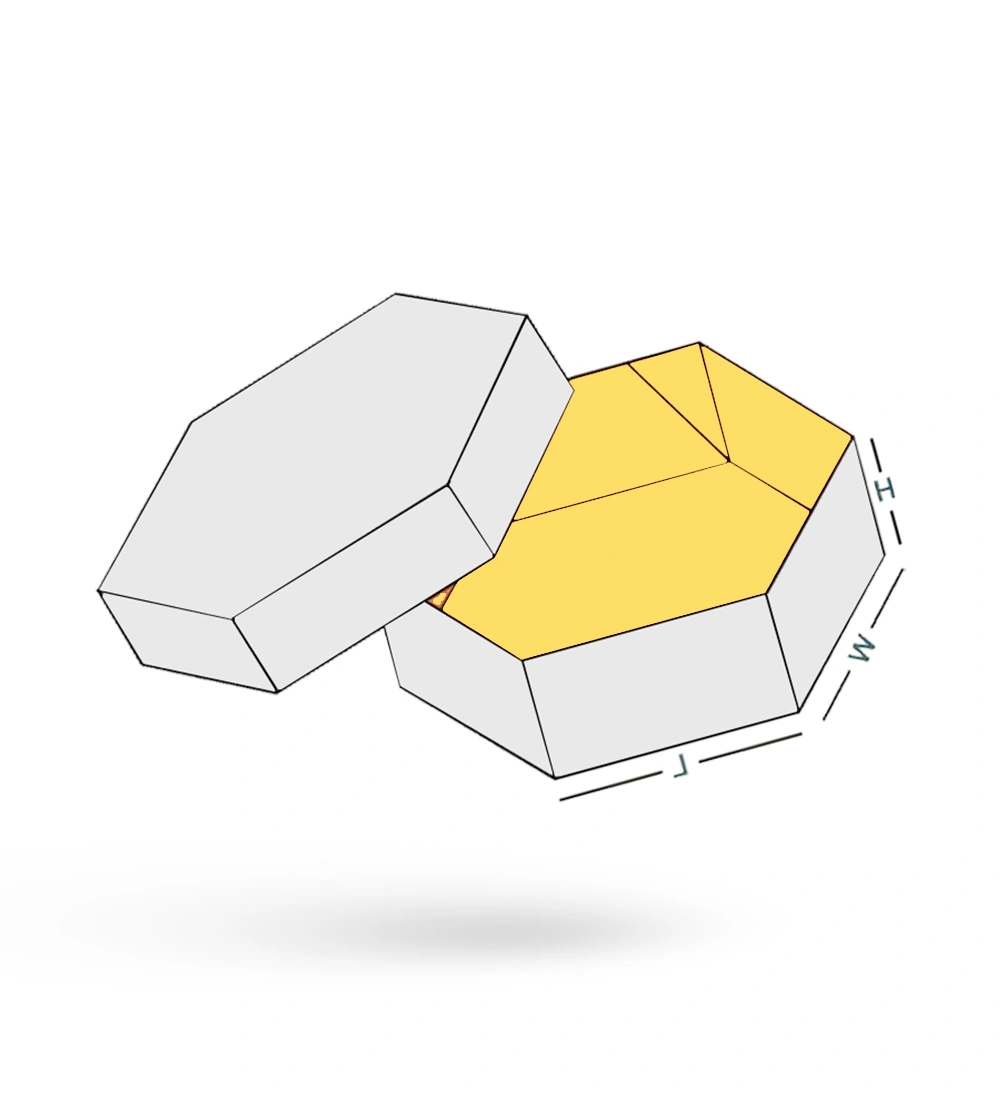

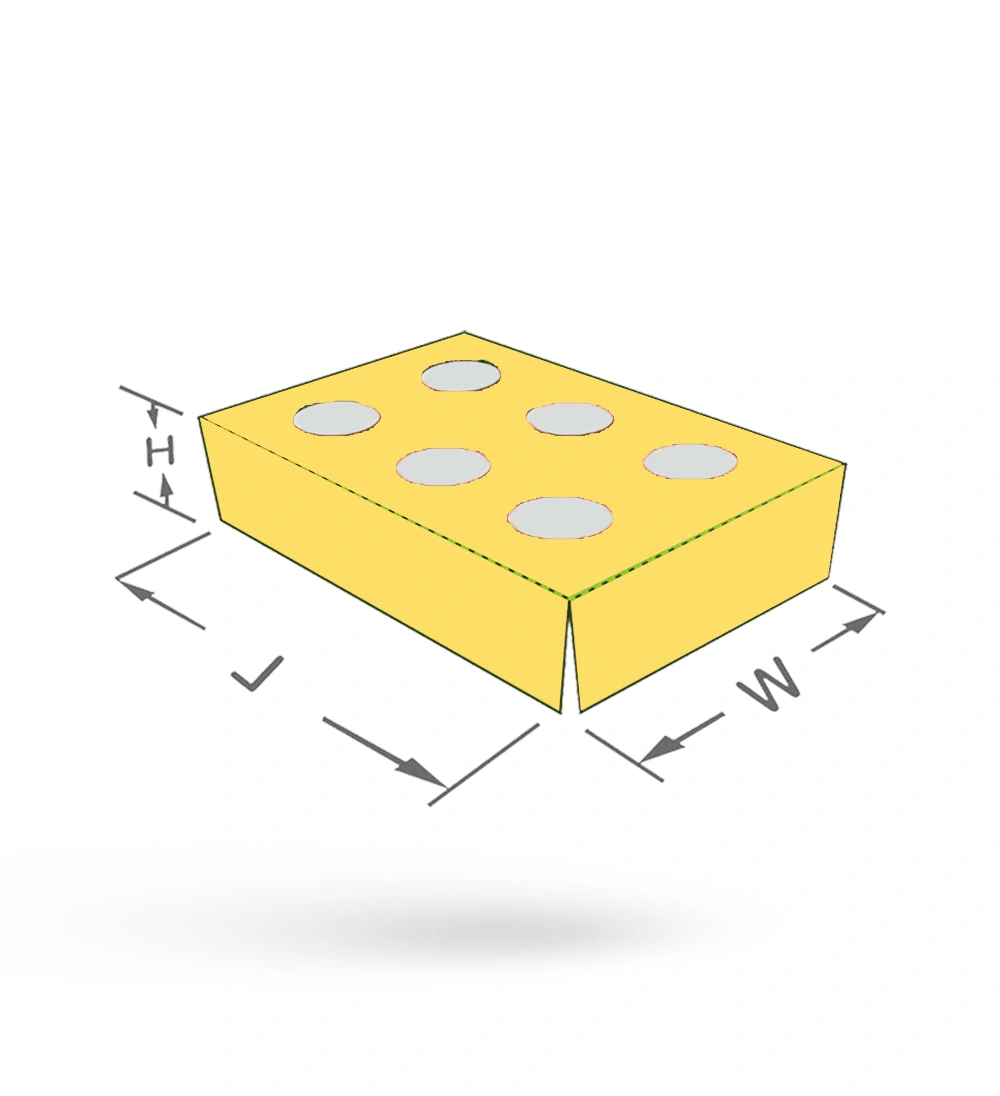

Sizes, Dimensions & Customization: A Perfect Fit for Your Product

At Haul Packaging, we understand that a one-size-fits-all approach leads to wasted space and increased risk of damage. Our process is built around creating a custom size solution for you.

- Fully Customizable Dimensions: We manufacture your product's exact length, width, and depth. A precise fit minimizes internal movement, which is a primary cause of in-transit product damage.

- Closure Customization: We can engineer the tuck front closure to be a single-panel tuck, a double-panel "lock-style" tuck, or even a reverse tuck, depending on your aesthetic and functional needs.

- Load Testing: For heavy products, we can design and test the box to ensure its load-bearing capacity meets or exceeds your requirements, providing peace of mind.

You can also pair your packaging with branded inserts or correspondence using our Custom Envelopes, a refined touch that enhances your customer experience.

Custom Printing & Finishing: Make a Lasting Impression

A box this durable will be seen and handled multiple times. That makes it a powerful mobile billboard for your brand.

-

-

Printing Processes:

- Direct-to-Corrugated Printing: Advanced flexographic and digital printing that applies vibrant, high-quality graphics directly onto the corrugated surface. Ideal for most e-commerce and subscription box applications.

- Litho Lamination: For the ultimate print quality, your design is offset printed on a separate sheet of paper and then laminated to the corrugated board. This process delivers photorealistic quality for luxury brands and high-end retail packaging.

-

-

Branding Applications:

-

- Full-Brand Wraps: Utilize the entire surface area to tell your brand story with stunning visuals.

- Tactile Finishes: Add a layer of soft-touch lamination to make the box feel as premium as it looks.

- Informational Printing: Include instructions, QR codes, or promotional messages directly on the box.

Cost & Pricing: Investing in Protection and Perception

While the per-unit cost is higher than a standard box, a Double Wall Tuck Front Box is an investment that pays for itself by reducing product damage, enhancing brand value, and improving customer satisfaction.

Key Factors Influencing Cost:

- Quantity: Bulk orders significantly reduce the per-unit cost due to setup and manufacturing efficiencies.

- Materials: The choice between BC-flute and EB-flute, as well as the liner grade, directly impacts the price.

- Size: Larger boxes use more material.

- Printing: Basic printing is economical, while full color printing and premium litho lamination add cost but also significant marketing value.

Sample Pricing Table (for estimation purposes only):

| Quantity | BC Flute Kraft (2-Color Print) | EB Flute White-Top (Full Color Direct Print) |

| 500 Units | ~ $3.75 - $5.50 per unit | ~ $5.25 - $7.50 per unit |

| 1,000 Units | ~ $2.80 - $4.25 per unit | ~ $4.00 - $6.00 per unit |

| 5,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why This Box is a Smart Business Decision

- Single-Wall Tuck Boxes: Provides dramatically better protection for fragile or heavy items, reducing shipping damage and associated costs.

- Taped RSCs (Regular Slotted Cartons): The tuck closure offers a cleaner, more premium look and a better user experience. The auto-bottom also makes assembly faster than sealing a base with tape.

- Rigid Boxes: Offers similar perceived quality and a great unboxing feel at a lower cost and with easier, flat storage before assembly.

Why Choose Haul Packaging for Your Tuck Front Boxes?

- USA-Based Manufacturing & Expertise: We understand the specific demands of American logistics and consumer expectations.

- Structural Integrity Focus: We engineer our boxes to perform, ensuring the closure is secure and the walls can withstand stacking.

- Rapid Prototyping: We can provide a physical prototype so you can test the fit, function, and feel before your full production run.

- Dedicated Customer Partnership: You'll work with a dedicated packaging expert who will guide you from concept to delivery.

Frequently Asked Questions (FAQ)

Q: How secure is the tuck closure during shipping?

A: When properly engineered, the tuck front closure is very secure. We die-cut the tabs to create a precise, friction-fit lock that will not come open under normal shipping conditions. For extremely heavy items, we can design a double-panel lock for added security.

Q: Can I get a sample before placing my full order?

A: Absolutely. We strongly recommend ordering a tuck box sample to evaluate the construction quality, test the closure mechanism, and see the print quality firsthand. Contact us to arrange a sample kit.

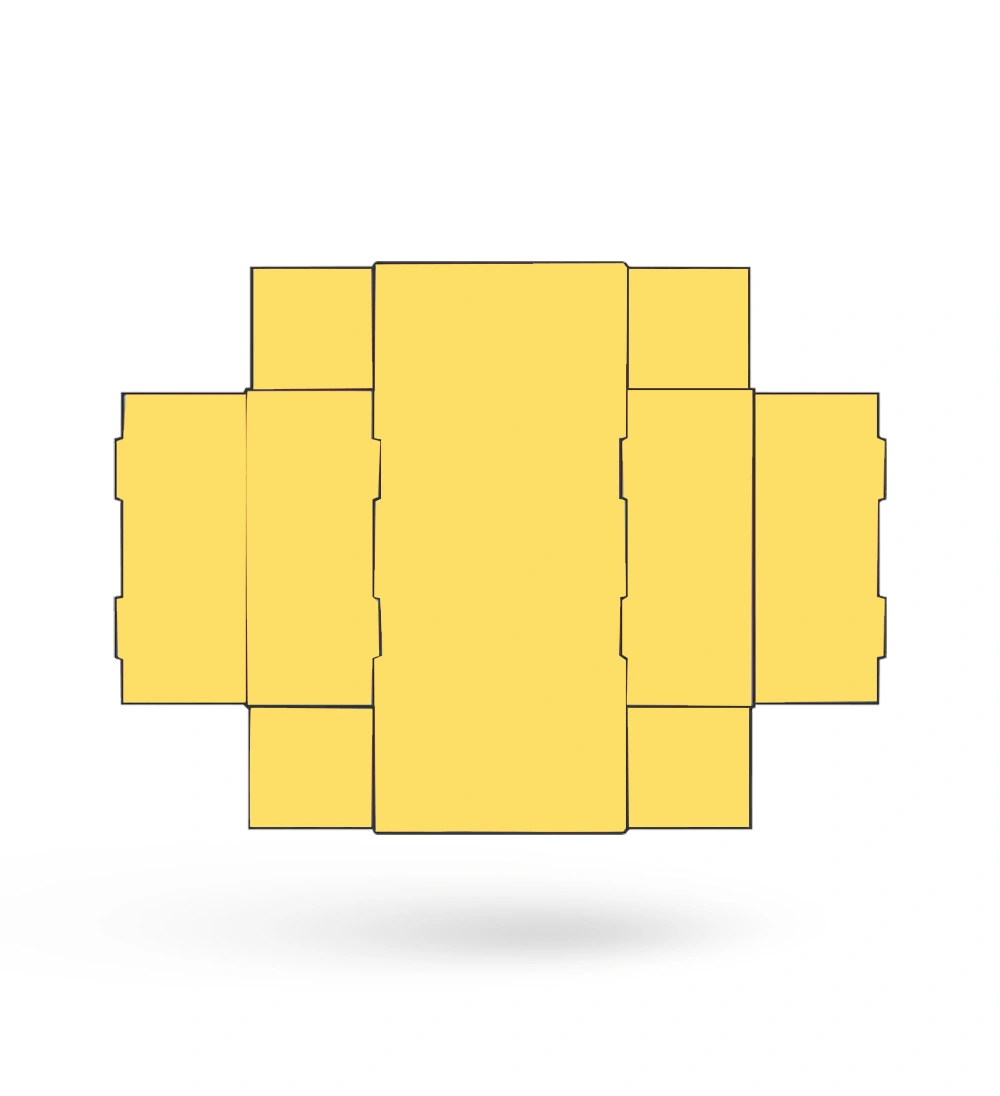

Q: Are these boxes shipped flat?

A: Yes. All our Custom Double Wall Tuck Front Boxes are shipped and stored flat to minimize storage space and shipping costs. The auto-bottom and tuck front are designed for quick, easy assembly without tape.

Q: Are these boxes recyclable?

A: Yes. Corrugated cardboard is one of the most widely recycled materials in the USA. Our boxes are fully recyclable, making them an eco-friendly packaging choice.

Ready to Upgrade Your Packaging with Haul Packaging?

Stop choosing between strength and sophistication. At Haul Packaging ,with our Custom Double Wall Tuck Front Boxes, you get both. This is the intelligent packaging solution for brands that are serious about protection, presentation, and customer satisfaction.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |