Custom Punch Inserts

We are a trusted Custom Punch Insert Manufacturer and Supplier, providing comprehensive Wholesale solutions for product security. Our expertise includes creating precise Custom Punch Inserts using various materials like foam and cardboard, ensuring your items remain stationary and protected within their packaging, reducing returns and enhancing the customer unboxing experience.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Custom Punch Inserts | Precision Product Protection | Haul Packaging

In the world of packaging, the journey from your facility to your customer's hands is fraught with potential hazards. Drops, impacts, and vibrations can turn a perfect product into a damaged return. Standard packaging materials like bubble wrap and loose fill are often insufficient for high-value, fragile, or complex-shaped items. At Haul Packaging, we've engineered the definitive solution: Custom Punch Inserts. These precision-engineered components transform ordinary boxes into fortified, presentation-grade packaging that guarantees your products arrive in pristine condition.

Explore our Custom Seal End Auto Bottom Boxes for durable and efficient packaging designs that combine strength and easy assembly.

This comprehensive guide will explore the science, materials, and applications of Custom Punch Inserts. We'll demonstrate how this targeted approach to product protection can dramatically reduce damage rates, enhance brand perception, and create an unforgettable unboxing experience that sets your brand apart in the competitive American marketplace.

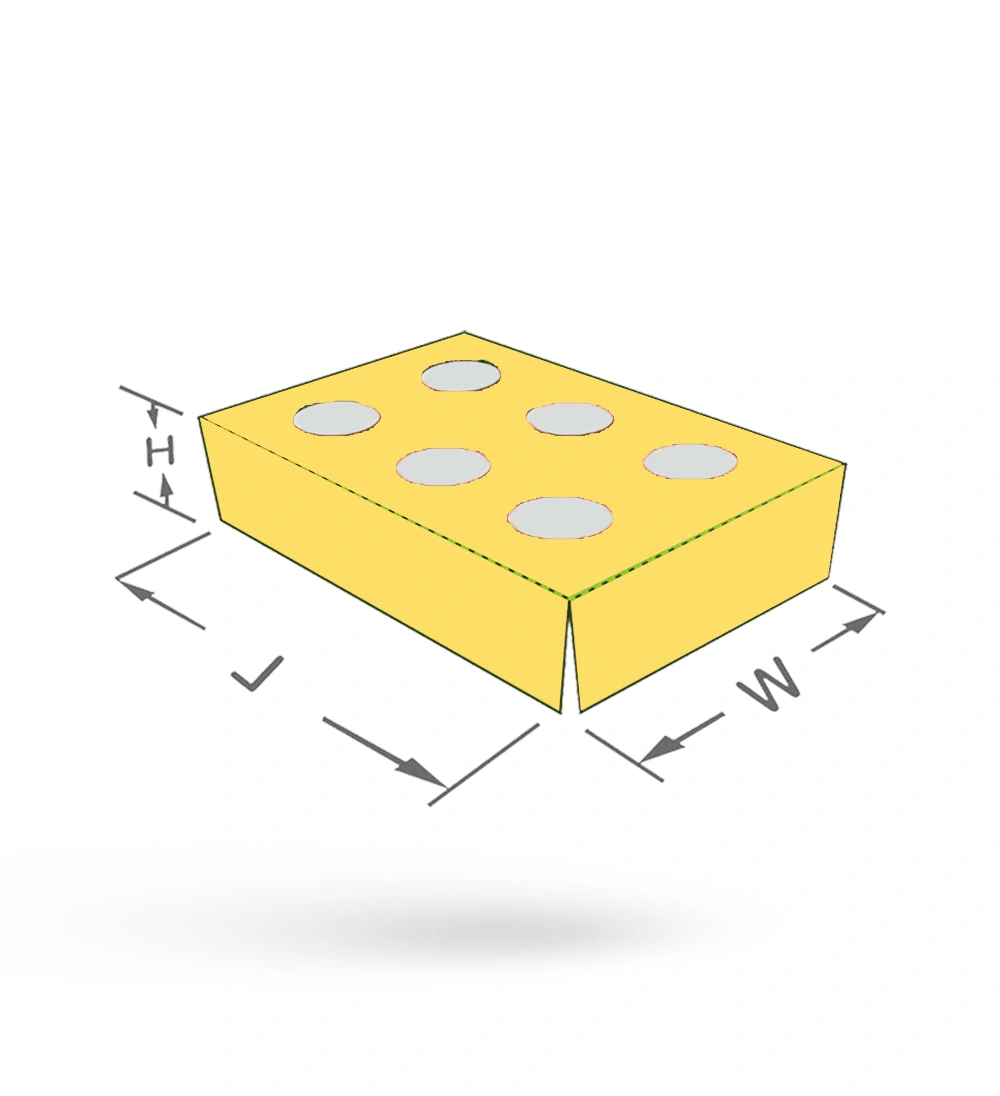

What Are Custom Punch Inserts?

Custom Punch Inserts are precision-cut components designed to hold and protect products securely within their packaging. Unlike generic cushioning materials, they are engineered to your product's exact dimensions and contours, creating a custom-fitted protective cradle.

You can also explore Custom Seal End Boxes that offer reliable sealing and premium structural integrity for secure product shipping.

The manufacturing process involves:

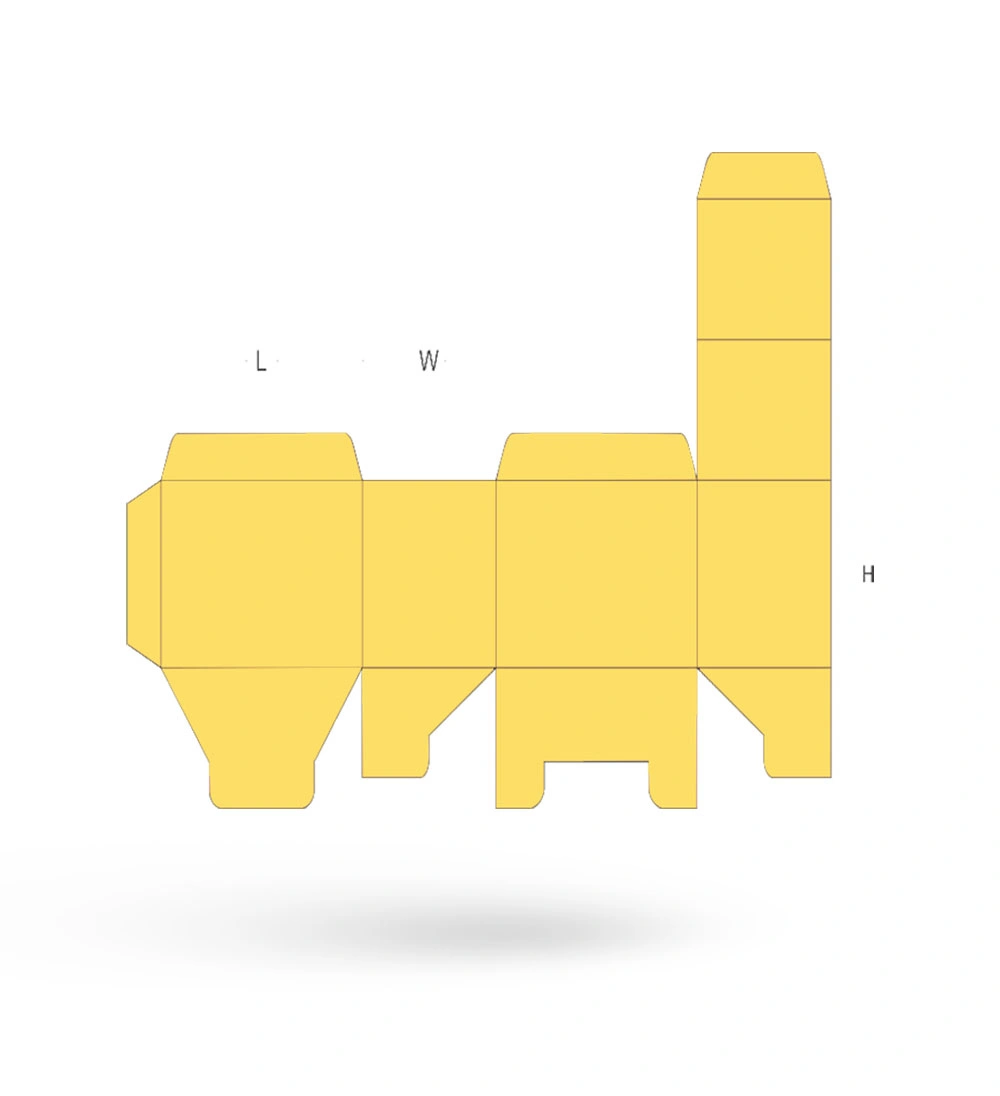

- Precision Die-Cutting: Using custom-made steel rule dies to cut specific shapes from various materials with extreme accuracy.

- CNC Routing: Computer-controlled cutting for complex 3D shapes and intricate designs that require multi-depth cavities.

- Custom Tooling: Creating bespoke cutting tools specifically for your product's unique geometry and protection requirements.

These inserts solve critical packaging challenges by eliminating product movement, absorbing shock, and preventing surface contact that causes scratches and abrasions.

Industries Served: Protection for Every Precision Need

The ability to create custom-fitted protection makes punch inserts indispensable across numerous industries where product integrity is non-negotiable.

| Industry | Primary Use Case | Key Benefit |

| Electronics & Technology | Protecting smartphones, tablets, laptops, and sensitive components from impact and electrostatic discharge. | Prevents costly damage to screens, circuits, and delicate components during shipping and handling. |

| Wine & Spirits | Securing bottles in gift sets and shipping containers to prevent breakage and label damage. | Eliminates bottle-to-bottle contact and provides cushioning against impacts during transit. |

| Medical Devices | Packaging sterile instruments, diagnostic equipment, and sensitive medical electronics. | Ensures compliance with regulatory standards while protecting life-saving equipment. |

| Cosmetics & Luxury Goods | Presenting high-end perfumes, skincare, and jewelry in elegant, secure packaging. | Combines superior protection with premium presentation that enhances brand perception. |

| Industrial Manufacturing | Shipping precision parts, machinery components, and sensitive instruments between facilities. | Prevents damage to expensive industrial components that could cause production downtime. |

Materials & Construction: The Science of Superior Protection

The effectiveness of a Custom Punch Insert depends on selecting the right material for your specific protection needs. We offer a range of options with distinct performance characteristics.

-

Foam Materials:

-

- Polyethylene Foam (EPE): A durable, flexible closed-cell foam that offers excellent cushioning and water resistance. Ideal for electronics packaging and general product protection.

- Expanded Polystyrene (EPS): A rigid, lightweight foam known for its superior shock absorption. Perfect for heavy items and products that require structural support.

- Polyurethane Foam: Offers varying densities for customized cushioning performance, from soft surface protection to firm structural support.

-

Paper-Based Materials:

- Corrugated Cardboard: An eco-friendly, cost-effective option for lightweight products and retail packaging. Can be die-cut into intricate product retention structures.

- Molded Pulp: Made from recycled paper, this sustainable option provides excellent cushioning and is ideal for eco-friendly packaging solutions.

-

Specialty Materials:

- Anti-Static Foams: Essential for electronics packaging to prevent damage from electrostatic discharge.

- Plastic Blisters: Clear plastic shells that provide excellent product visibility while offering secure containment.

Pair your insert designs with Custom Sleeve and Tray Boxes for a premium unboxing experience that enhances both presentation and protection.

Design Options & Configurations: Tailored Protection Solutions

Custom Punch Inserts can be engineered in various configurations to meet specific protection and presentation requirements.

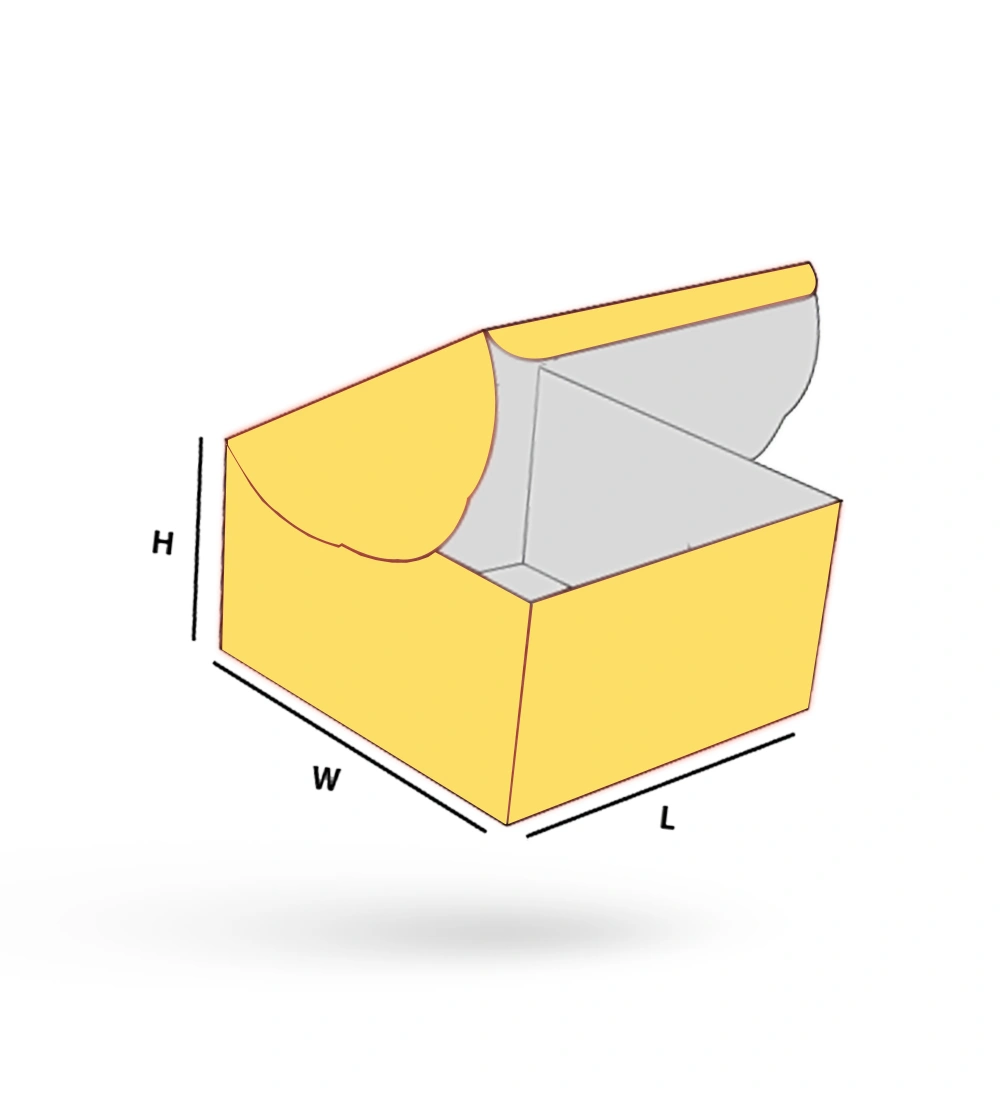

- Single-Layer Inserts: Basic protection for products that primarily need scratch prevention and minimal cushioning.

- Multi-Layer Trays: Complex systems with multiple layers that separate components or create tiered presentations.

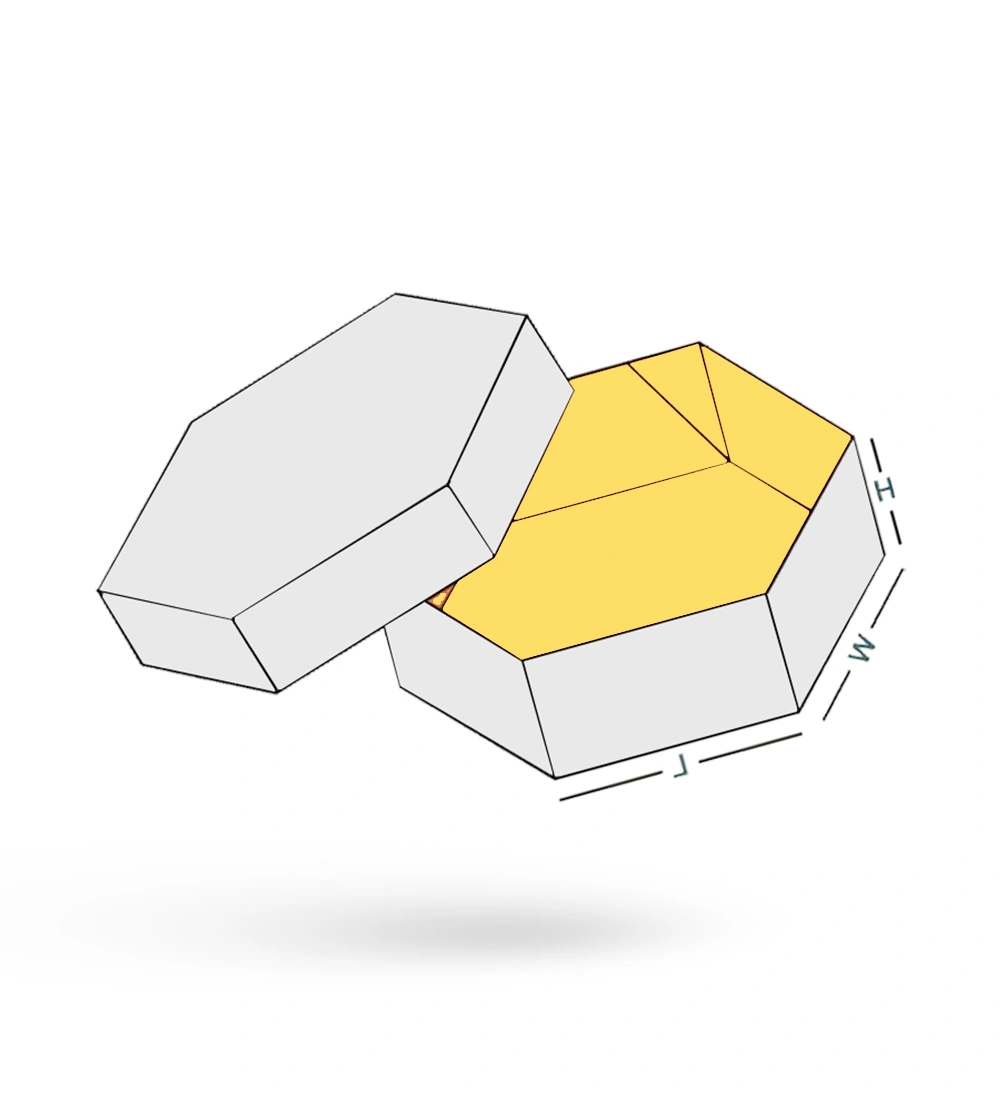

- Hinged Designs: Two-piece designs that clasp around products for maximum security and dramatic reveals.

- Modular Systems: Interlocking inserts that can be configured differently for various product combinations.

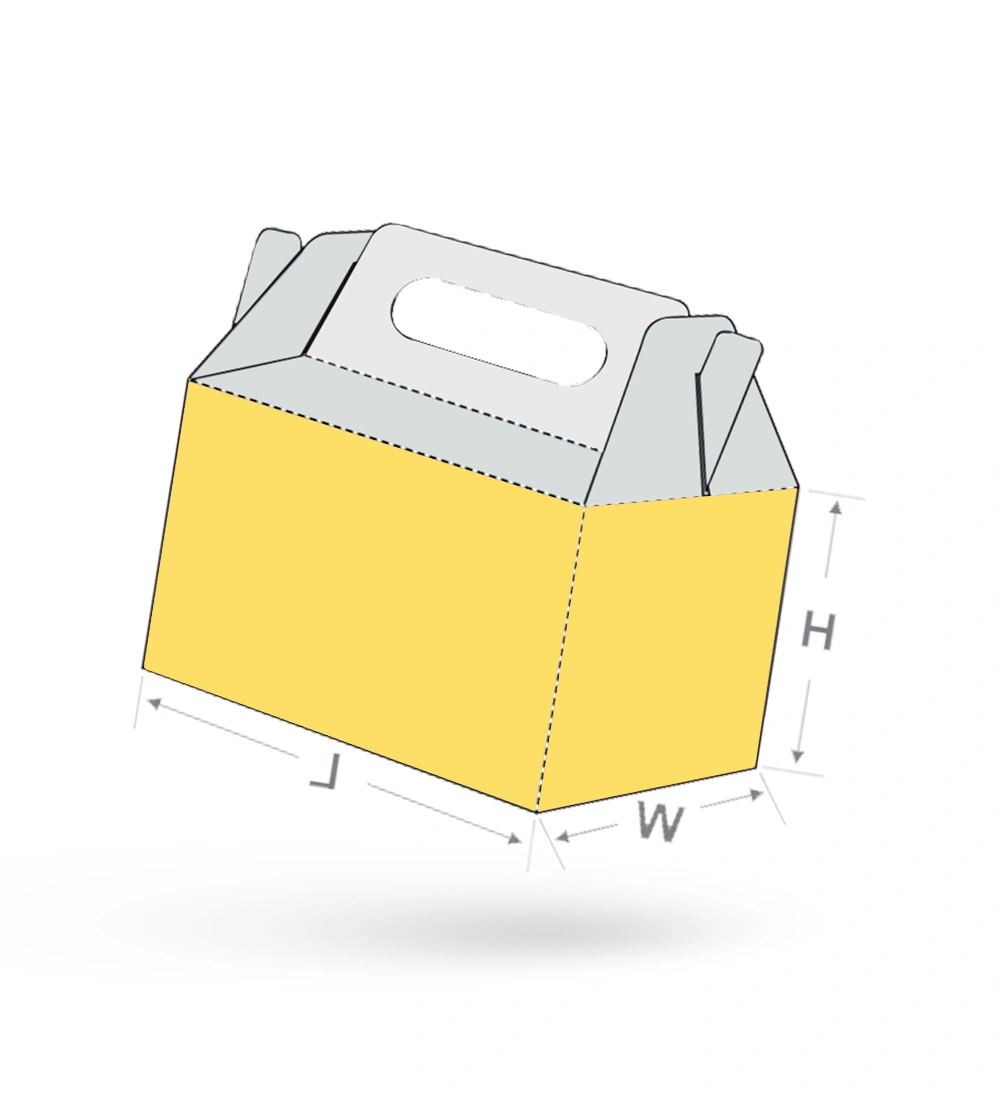

Sizes & Capabilities: Precision Without Compromise

At Haul Packaging, we specialize in creating truly custom size inserts tailored to your product's exact specifications.

- Maximum Sheet Size: We can produce inserts up to 48" x 96" for large-format applications.

- Tight Tolerances: Our precision die-cutting maintains tolerances of ±0.015" for perfect product fits.

- Complex Geometries: We can create intricate cutouts, finger access points, and multi-depth cavities.

- Rapid Prototyping: We provide quick-turn prototypes to test fit and function before full production.

Custom Printing & Branding: Protection with Presentation

While primarily functional, Custom Punch Inserts also offer opportunities for branding and enhanced user experience.

-

Printing Options:

-

-

- Direct Printing: Apply logos, instructions, or branding directly to foam and cardboard surfaces.

- Label Application: Add pre-printed labels to insert surfaces for branding or product information.

-

-

Color Options:

-

-

- Standard Colors: Black, white, and gray foams for clean, professional appearance.

- Custom Colors: Match your brand colors for cohesive packaging experiences.

-

-

Surface Treatments:

-

- Flocking: Add a velvety surface for ultra-luxurious product presentation.

- Laminates: Apply protective coatings or decorative surfaces.

Cost & Pricing: Investing in Damage Prevention

The cost of Custom Punch Inserts is an investment that pays for itself by eliminating product damage, reducing returns, and enhancing brand value.

Key Factors Influencing Cost:

- Material Selection: The type and density of foam or other material significantly impact cost.

- Tooling Requirements: Custom die creation represents an initial investment but reduces per-unit costs for larger runs.

- Complexity: Intricate designs with multiple cavities and tight tolerances require more manufacturing time.

- Quantity: Bulk orders dramatically reduce the per-unit cost through manufacturing efficiencies.

Sample Pricing Table (for estimation purposes only):

| Quantity | EPE Foam Insert (Single Cavity) | Multi-Layer Corrugated Tray |

| 1,000 Units | ~ $1.50 - $3.00 per unit | ~ $0.75 - $1.50 per unit |

| 5,000 Units | ~ $0.90 - $2.00 per unit | ~ $0.45 - $1.00 per unit |

| 25,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why Custom Punch Inserts Are a Strategic Business Decision

- Loose Fill Materials: Provides superior, consistent protection while using less material and creating a more professional presentation.

- Generic Foam Inserts: Offers perfect product-specific fit versus one-size-fits-all solutions that often leave products vulnerable to damage.

- Molded Pulp: Delivers more consistent performance and better aesthetics for high-value products.

Why Choose Haul Packaging for Your Punch Inserts?

- USA-Based Engineering Expertise: We combine American manufacturing precision with deep expertise in protective packaging design.

- Material Science Knowledge: Our specialists help select the optimal material and density for your specific protection needs.

- Design Partnership: We work as an extension of your team, from initial concept through production and delivery.

- Quality Assurance: Every insert is inspected to ensure precise dimensions and consistent quality.

Frequently Asked Questions (FAQ)

Q: How do I get started with custom punch inserts?

A: Simply provide us with a product sample or detailed CAD drawings. We'll analyze your protection needs and recommend the optimal material and design solution.

Q: Can I get a prototype before full production?

A: Absolutely! We strongly recommend prototyping to test fit, function, and protection performance. Contact us to arrange a prototype sample.

Q: What's the typical lead time for custom inserts?

A: Production time typically ranges from 2-4 weeks, depending on complexity and order quantity. Prototypes can often be delivered within 5-7 business days.

Q: Are your foam inserts environmentally friendly?

A: We offer several eco-friendly packaging options, including recyclable polyethylene foams and paper-based alternatives. We can help you select the most sustainable solution for your needs.

Ready to Eliminate Product Damage with Haul Packaging?

Stop accepting packaging damage as a cost of doing business. Invest in Haul Packaging’s Custom Punch Inserts to ensure your products arrive perfectly every time, while creating a premium unboxing experience that strengthens your brand.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |