Custom Seal End Boxes

We are a trusted Custom Seal End Boxes Manufacturer and Supplier, providing comprehensive Wholesale solutions for secure packaging needs. Our expertise includes creating high-quality Custom Printed Seal End Boxes that feature sturdy construction and reliable tuck-end closures, making them ideal for packaging everything from consumer goods and food products to industrial parts and retail merchandise.

--------Guarenteed safe checkout--------

.png)

.png)

.png)

.png)

.png)

No Die & Plate

Charges

Quick turnaround

time

Free & Shipping

Starting from

50 boxes

customize size

& style

free graphics

designing

- Details

- Specifications

Custom Seal End Boxes | Secure & Professional Packaging | Haul Packaging

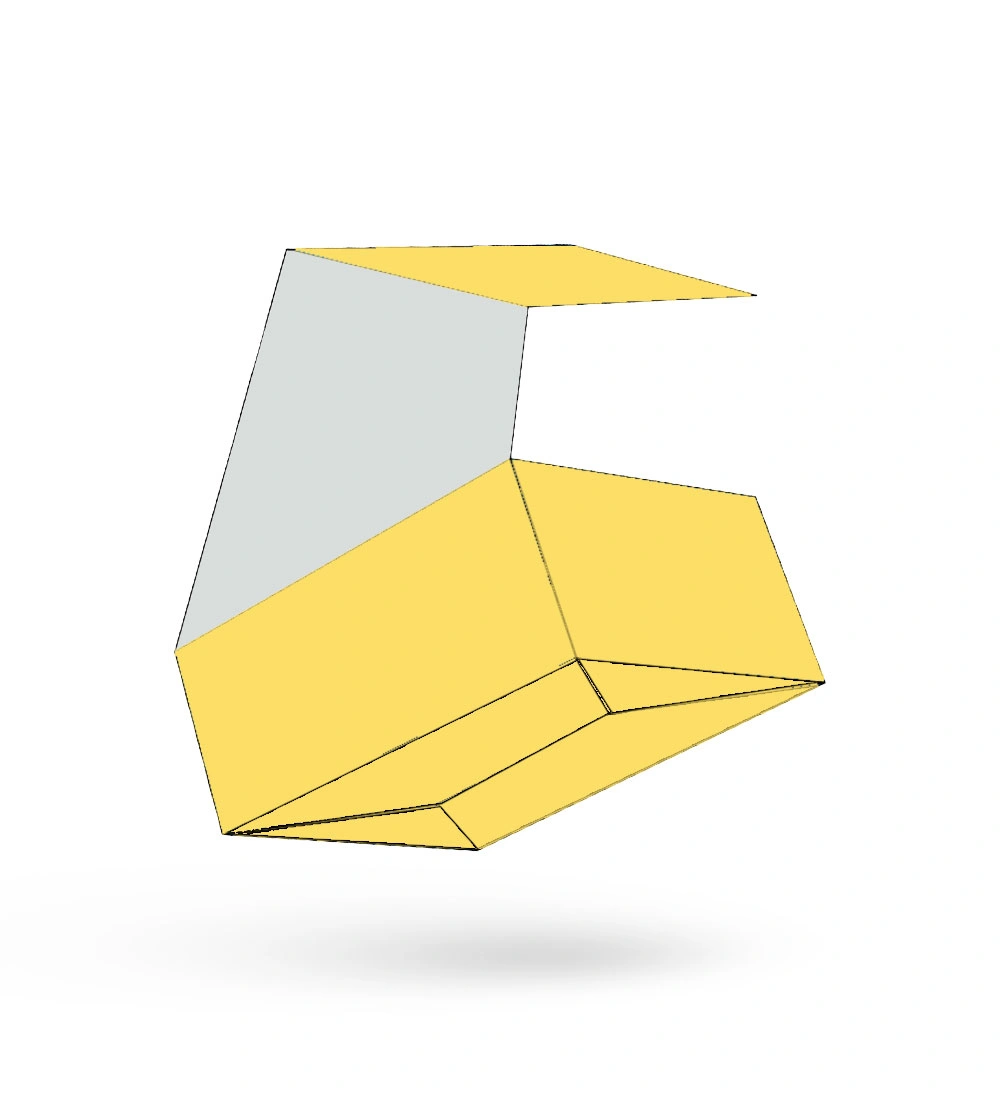

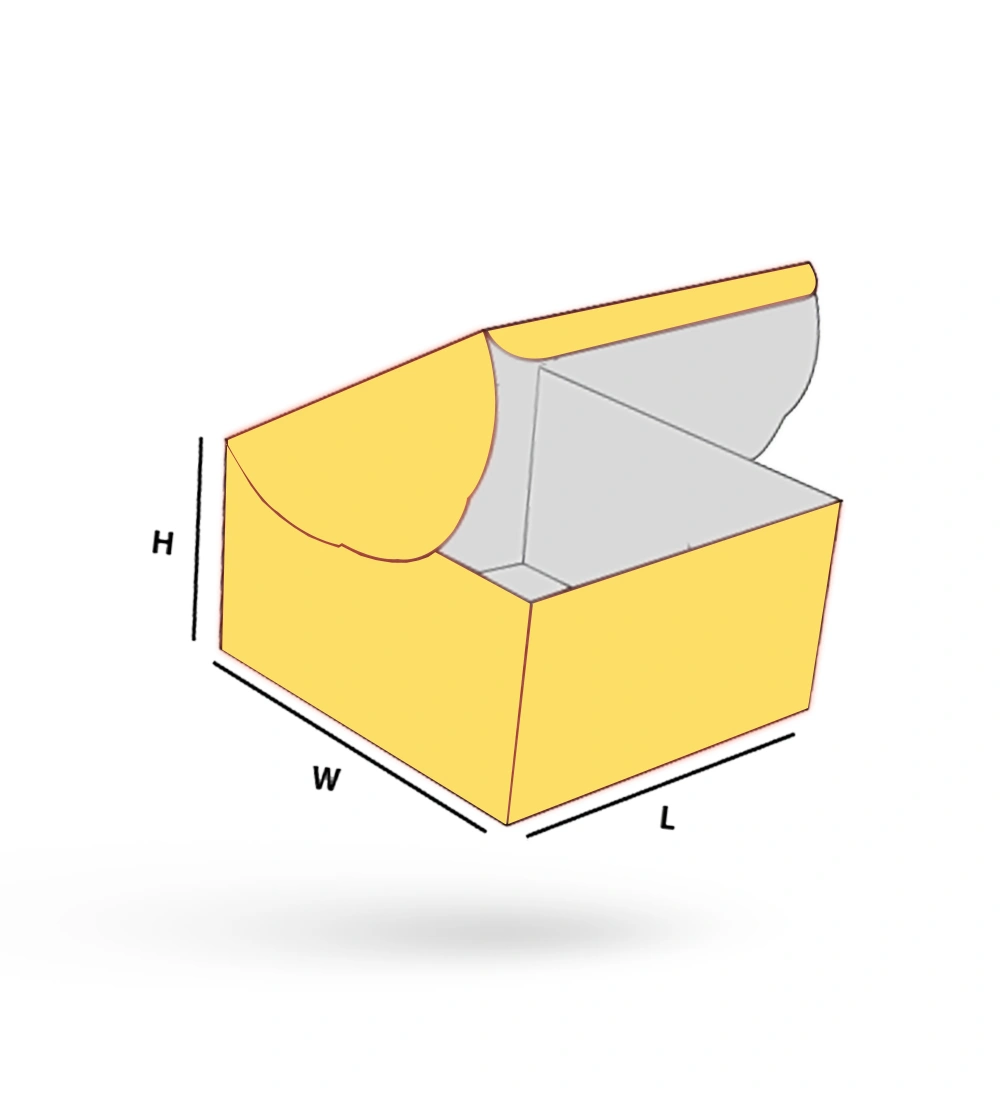

In an era where product integrity and brand perception are paramount, the choice of packaging can make or break the customer experience. While many boxes rely on friction-based closures, there are situations where only the absolute certainty of a permanent seal will suffice. At Haul Packaging, we specialize in Custom Seal End Boxes—the definitive solution for brands that refuse to compromise on security, durability, and professional presentation.

Characterized by their permanently glued or taped ends, these boxes provide a level of protection and tamper-resistance that traditional folding cartons simply cannot match. This comprehensive guide will explore the engineering, applications, and significant advantages of Custom Seal End Boxes, demonstrating why they are the trusted choice for industries where product security is non-negotiable.

Custom Punch Inserts are another great option for businesses that prioritize protection and a flawless product fit, offering a secure and premium unboxing experience alongside seal end styles.

What Are Seal End Boxes?

Custom Seal End Boxes are a type of packaging where the ends are permanently closed using adhesive or tape, creating a secure, tamper-resistant container. Unlike tuck-style boxes that can be easily opened and reopened, seal end boxes are designed for single-use security from the point of packing to the final unboxing by the customer.

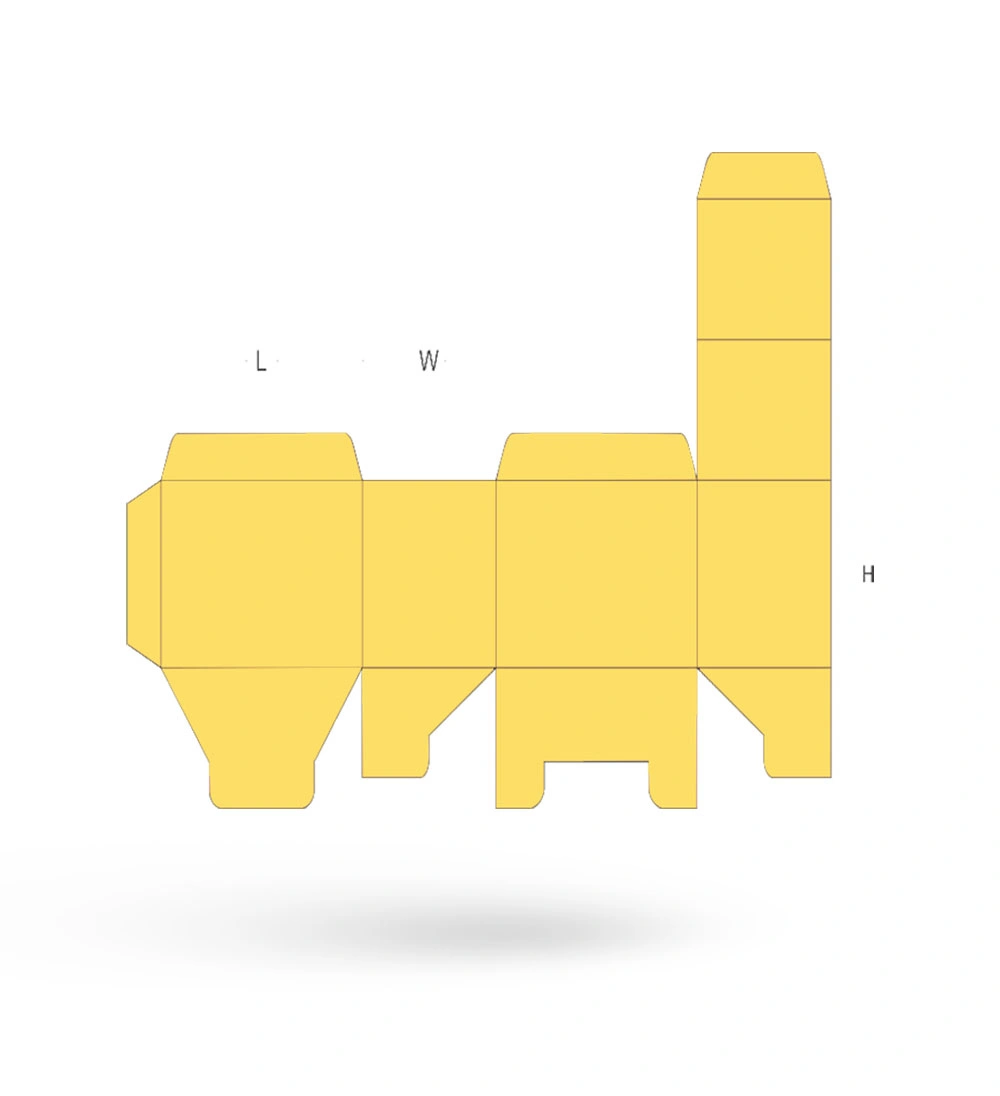

Key structural characteristics include:

- Permanent End Closures: The most defining feature, where the box ends are sealed with glue or tape, creating a continuous, unbroken surface.

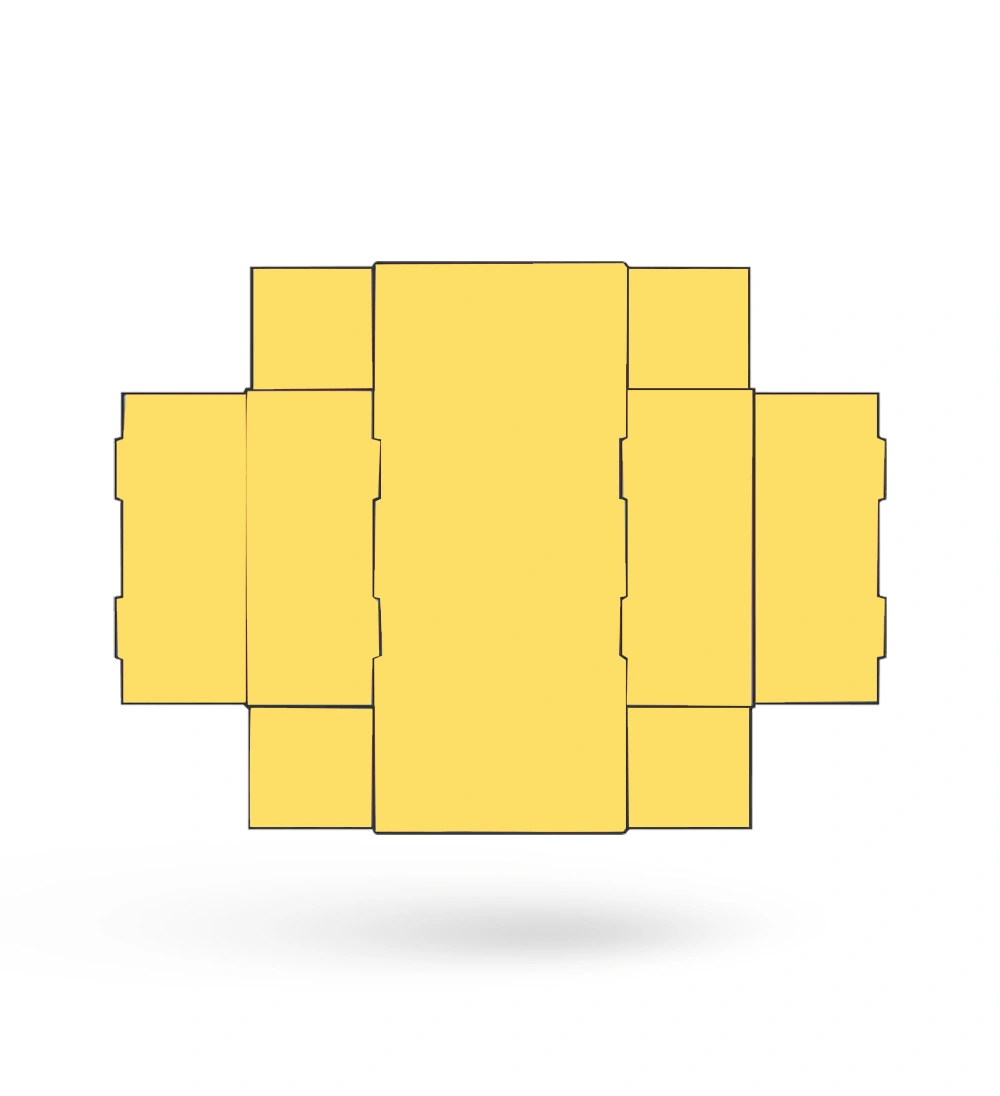

- Flat-Packed Delivery: These boxes are shipped and stored flat to maximize space efficiency, then assembled and sealed at the point of packing.

- Consistent Rectangular Shape: When assembled, they form a clean, uniform rectangular prism, ideal for stacking and palletizing.

- Superior Seam Integrity: The glued or taped seams provide enhanced structural rigidity compared to folded closures.

This design prioritizes product security and a pristine, unbroken exterior, making it ideal for shipping through complex supply chains.

Industries Served: Where Security is Paramount

The tamper-resistant nature and robust construction of seal end boxes make them indispensable across multiple sectors where product integrity cannot be left to chance.

| Industry | Primary Use Case | Key Benefit |

| Pharmaceutical & Healthcare | Packaging for over-the-counter medications, medical devices, and healthcare supplements. | Provides essential tamper-evident packaging that meets strict industry regulations and ensures patient safety. |

| Food & Beverage | Dry goods, gourmet food items, tea, coffee, and specialty food products. | Creates a barrier against contaminants and pests while maintaining product freshness and integrity. |

| E-commerce & Retail | Shipping electronics, cosmetics, and high-value items directly to consumers. | Offers superior protection against in-transit damage and provides customers with confidence in their purchase. |

| Cosmetics & Beauty | High-end skincare, makeup, and fragrance products where presentation and purity are crucial. | The clean, unbroken surfaces are perfect for luxury branding while ensuring product authenticity. |

| Electronics & Components | Sensitive electronic devices, components, and accessories that are susceptible to static or moisture. | The secure seal protects against environmental factors and prevents accidental opening during shipping. |

Materials & Construction: Built for Integrity and Performance

The effectiveness of a Custom Seal End Box is directly tied to the quality of its materials and the precision of its construction.

-

Paperboard Grades:

-

- SBS (Solid Bleached Sulfate): The premium choice for retail packaging. This bright white, clay-coated board offers a superior, smooth surface for high-fidelity printing and vibrant brand colors.

- CCNB (Clay-Coated News Back): A cost-effective and high-quality option featuring a brilliant white printable exterior and a grey recycled interior. Excellent for e-commerce shipping where both appearance and budget matter.

- Kraft Paperboard: The leading choice for eco-friendly packaging, providing a natural, rustic aesthetic and strong sustainability credentials.

- Recycled Board: Made with post-consumer waste content, appealing to brands and consumers with a strong environmental focus.

-

Sealing Methods:

- Hot Melt Glue: Creates a strong, fast-setting bond ideal for automated packaging lines. Offers a clean, almost invisible seam.

- Cold Glue: A cost-effective solution for manual application, providing a strong and reliable seal.

- Pressure-Sensitive Tape: Allows for quick sealing without waiting for glue to dry. The tape itself can also be custom printed for branding or tamper-evidence.

For baked goods that require extra presentation and protection, our Custom Six Corner Cake Boxes offer a durable, elegant solution with added structural strength.

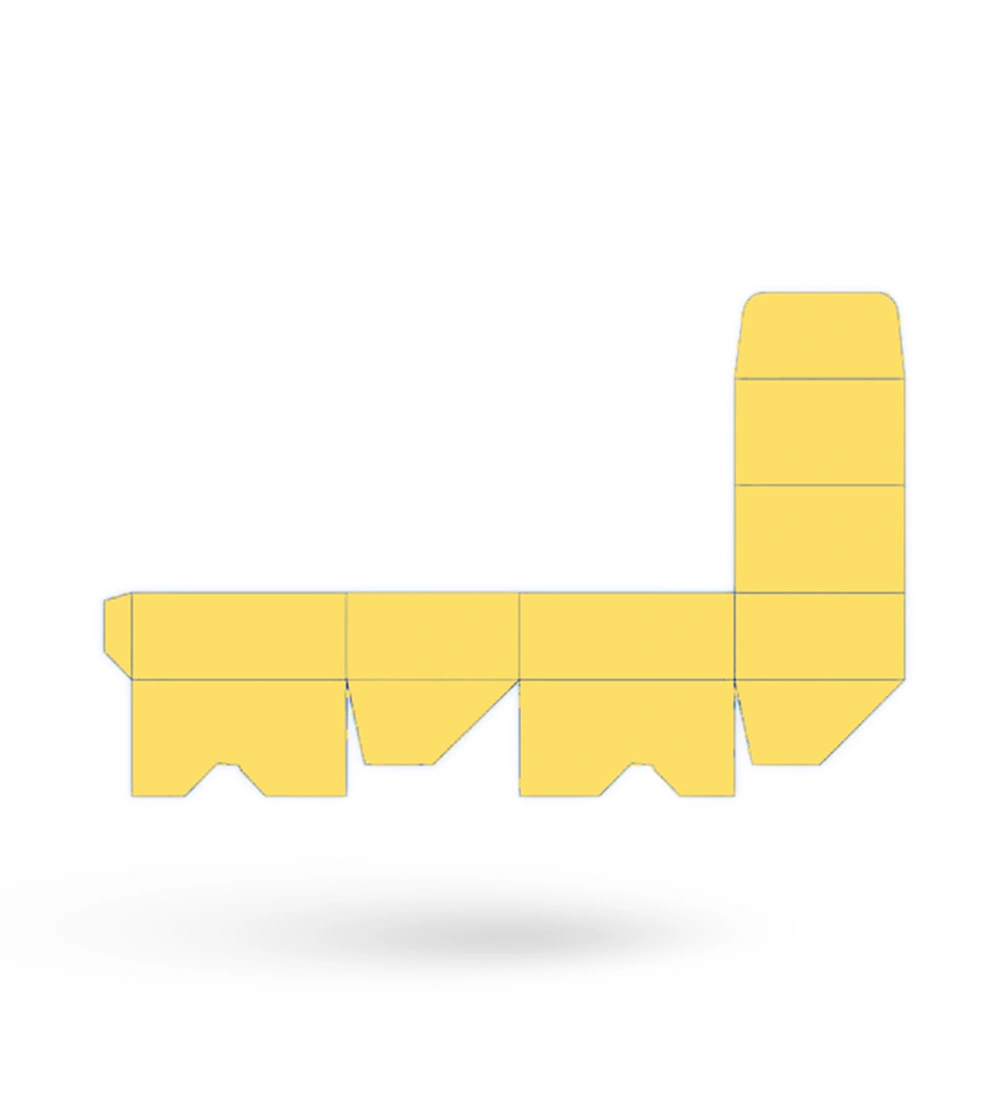

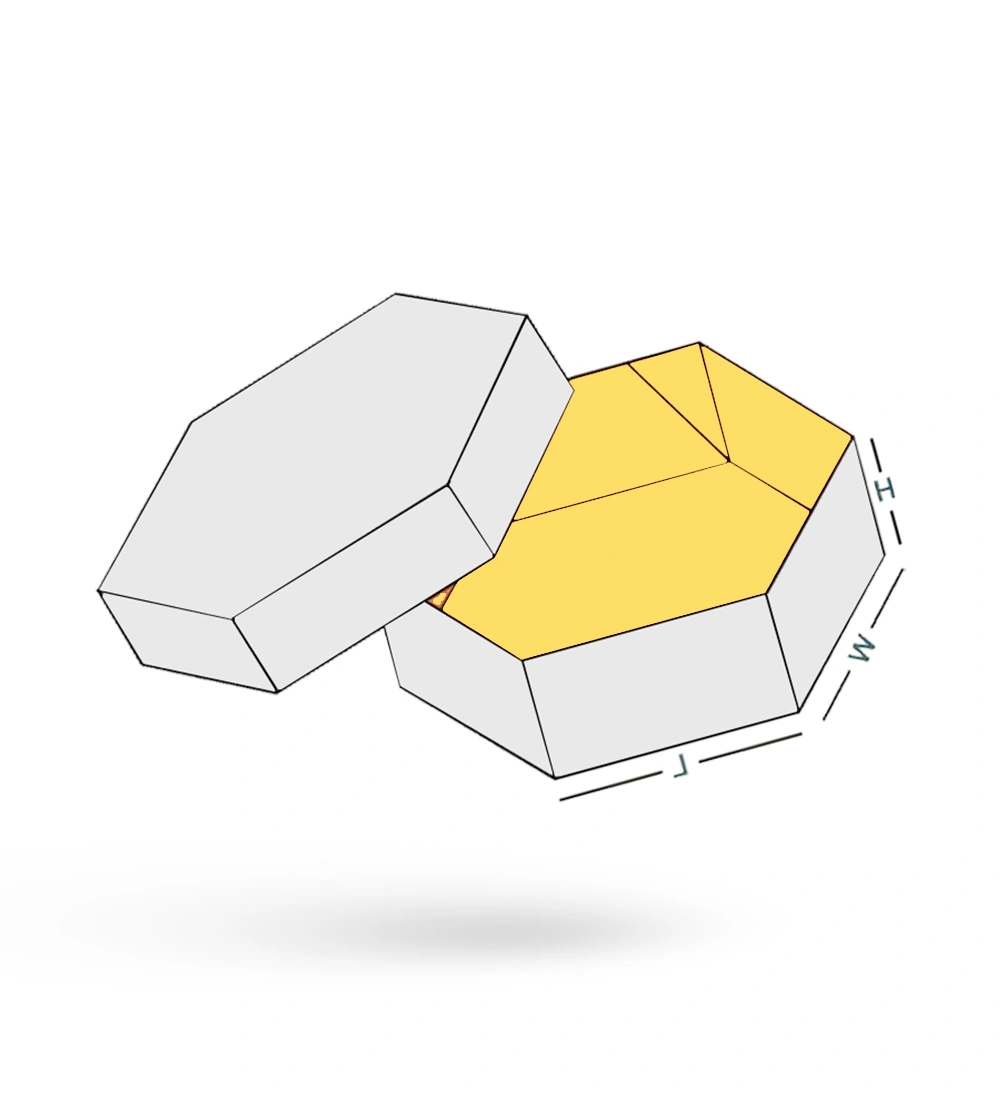

Box Styles & Configurations

While the sealed end is the constant, these boxes can be tailored to specific needs.

- Straight Seal End: The standard and most common configuration.

- Reverse Tuck with Seal End: Combines a tuck for easy customer opening with sealed ends for vendor-side security.

- Full Overlap Seal End (FOL): Features flaps that fully overlap, providing extra strength and rigidity for heavier products.

- Five-Panel Folder: Wraps the product completely, offering superior protection and a large, continuous print surface.

If your brand uses tray-based or sliding packaging systems, consider our Custom Sleeve and Tray Boxes, designed for premium presentation and practical usability.

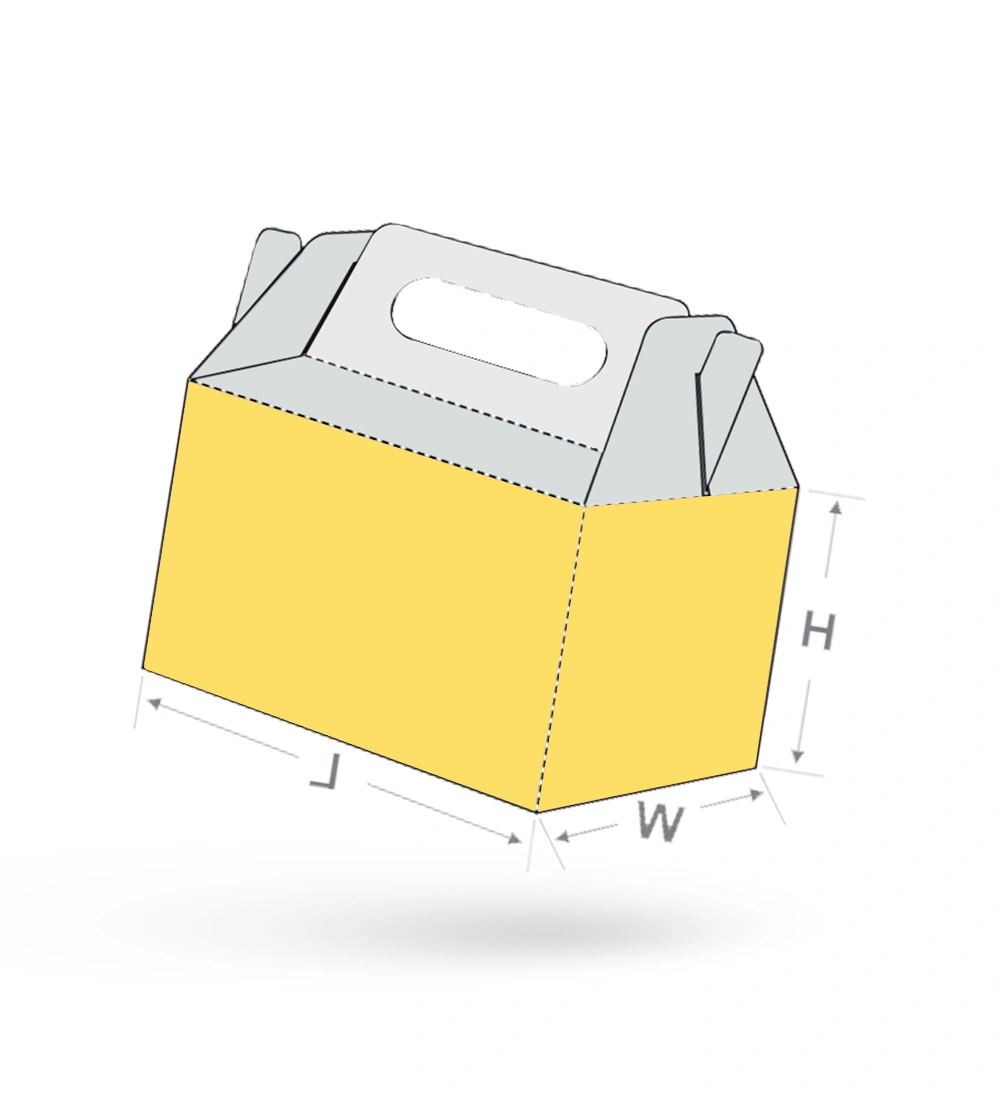

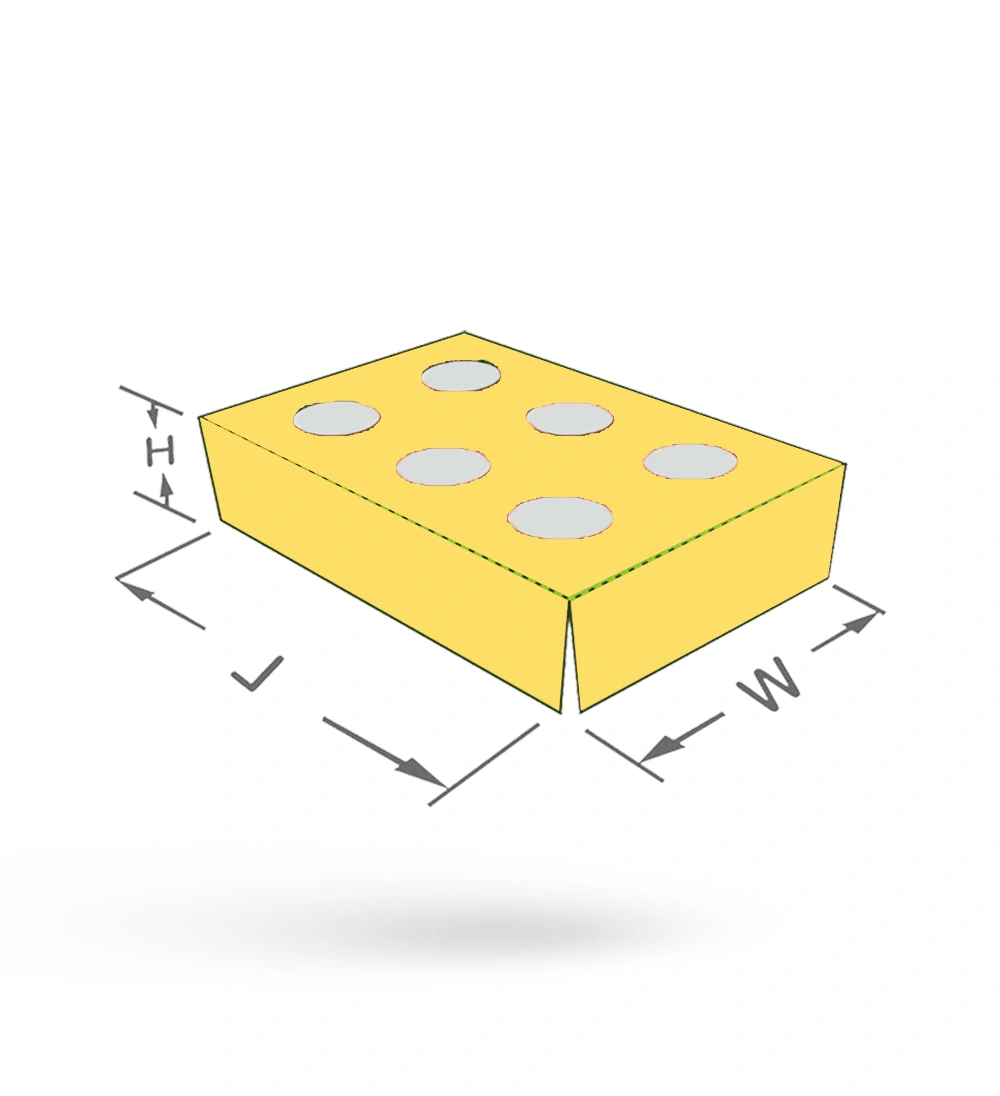

Sizes & Dimensions: A Precision Fit for Your Product

At Haul Packaging, we engineer custom size seal end boxes to minimize internal movement and maximize protection.

| Size Category | Common Dimensions (LxWxD) | Ideal Product Types |

| Small | 4" x 3" x 1" | Jewelry, small cosmetics, USB drives, samples |

| Medium | 8" x 6" x 2" | Smartphones, beauty products, small books, food items |

| Large | 12" x 10" x 4" | Tablets, apparel, multiple items, larger retail products |

| Extra Large | 16" x 12" x 6" | Shoes, tech accessories, gourmet gift sets, bulk items |

All dimensions are fully customizable to ensure a snug, protective fit for your specific product.

Custom Printing & Finishing: Branding a Secure Package

The large, flat, and unbroken panels of a seal end box provide a pristine canvas for your branding.

-

Printing Processes:

- Offset Printing: Delivers the highest quality for custom printing, with razor-sharp detail and perfect color matching. Essential for photorealistic images and intricate brand assets.

- Flexographic Printing: A cost-effective method for larger runs with solid colors and simpler graphics.

-

Premium Finishing Options:

- Aqueous Coating: A protective, water-based coating that resists scuffs and scratches while enhancing color vibrancy.

- Foil Stamping: Adds a luxurious, reflective element to your logo or design, creating a striking contrast on the matte box surface.

- Embossing/Debossing: Creates a raised or recessed texture, adding a tactile, high-end dimension that customers can see and feel.

- Spot UV: A high-gloss coating applied to specific areas to create dramatic visual contrast.

Cost & Pricing: Investing in Product Integrity

The cost of Custom Seal End Boxes is an investment in reducing product loss, building customer trust, and enhancing your brand's reputation for quality.

Key Factors Influencing Cost:

- Quantity: Bulk orders significantly reduce the per-unit cost through manufacturing and setup efficiencies.

- Materials: The choice between SBS, CCNB, or Kraft paperboard is a primary cost driver.

- Printing: Basic one-color printing is economical, while full color printing and premium finishes add cost and significant visual value.

- Size: Larger boxes use more material.

Sample Pricing Table (for estimation purposes only):

| Quantity | CCNB Paperboard (2-Color Print) | SBS Paperboard (Full Color + AQ Coating) |

| 1,000 Units | ~ $1.00 - $1.75 per unit | ~ $1.50 - $2.50 per unit |

| 5,000 Units | ~ $0.65 - $1.20 per unit | ~ $1.00 - $1.75 per unit |

| 25,000+ Units | Contact for bulk/wholesale discount! | Contact for bulk/wholesale discount! |

Why Seal End Boxes Are a Smart Business Decision

- Tuck End Boxes: Provides a significantly more secure, tamper-resistant closure. Tuck ends can pop open during shipping or be opened and closed without evidence, whereas a broken seal end is immediately obvious.

- Regular Slotted Containers (RSCs): Offers a more professional, finished appearance right out of the box, with clean lines and no exposed corrugated edges.

- Rigid Boxes: Delivers a high-quality, secure presentation at a much lower cost and with far more efficient storage (as they ship flat).

Why Choose Haul Packaging for Your Seal End Boxes?

- USA-Based Manufacturing & Expertise: We understand the specific needs and standards of the American market, from FDA requirements for food and pharma to the demands of e-commerce logistics.

- Precision Engineering: We ensure that our boxes are die-cut for perfect, easy assembly and that the glue flaps are designed for optimal adhesive application and bond strength.

- Quality Assurance: We rigorously test our seals for strength and consistency, ensuring your products are protected from our facility to your customer's doorstep.

- Dedicated Partnership: You will work with a packaging expert who will help you select the right material, sealant, and design for your specific product and application.

Frequently Asked Questions (FAQ)

Q: Are seal end boxes reusable?

A: Generally, no. The primary purpose of a seal end box is to provide a secure, tamper-evident closure. Once opened by cutting the tape or breaking the glue seal, the box cannot be rescued in its original state. This is a key feature for product security.

Q: Can I get a sample before placing my full order?

A: Absolutely. We strongly encourage ordering a seal end box sample to evaluate the material quality, print fidelity, and assembly process. Contact us to arrange a sample kit.

Q: Are these boxes suitable for automated packaging equipment?

A: Yes! Seal end boxes are excellent for automated lines. They are typically supplied flat and are designed to be erected, filled, and sealed efficiently by machinery. We can ensure our boxes are manufactured to the precise tolerances your equipment requires.

Q: What is the main advantage over a tuck end box?

A: The primary advantage is security. A tuck end can be opened and closed without leaving a trace, while a seal end provides a clear, irreversible indicator that the box has been opened. This builds customer trust and is essential for regulated industries.

Ready to Secure Your Products with Haul Packaging?

Stop risking product integrity with insufficient packaging. At Haul Packaging, Choose Custom Seal End Boxes to guarantee your products arrive securely, enhance your brand's professional image, and build unwavering trust with your customers.

| Dimensions | All Custom Sizes, Shapes and Styles. |

| Printing | CMYK, PMS, Screen Printing, No Printing |

| Paper Stock | 10PT to 28 PT (60lb to 400 lb) Eco Friendly Kraft Stock, E-Flute Corrugation, Bux Board, Cardstock, Fancy Cardstock. |

| Quantity | 100 - 500,000 |

| Coating | Gloss, Matte, Spot Uv |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up Physical Sampling, (On Request) |

| Turn Around Time | 4-6 Business Days, Rush Production Plans. |

| Shipping | Flat Shipping. |

| Delivery Courier | FedEx Express Shipping, DHL, UPS, Skynet! |