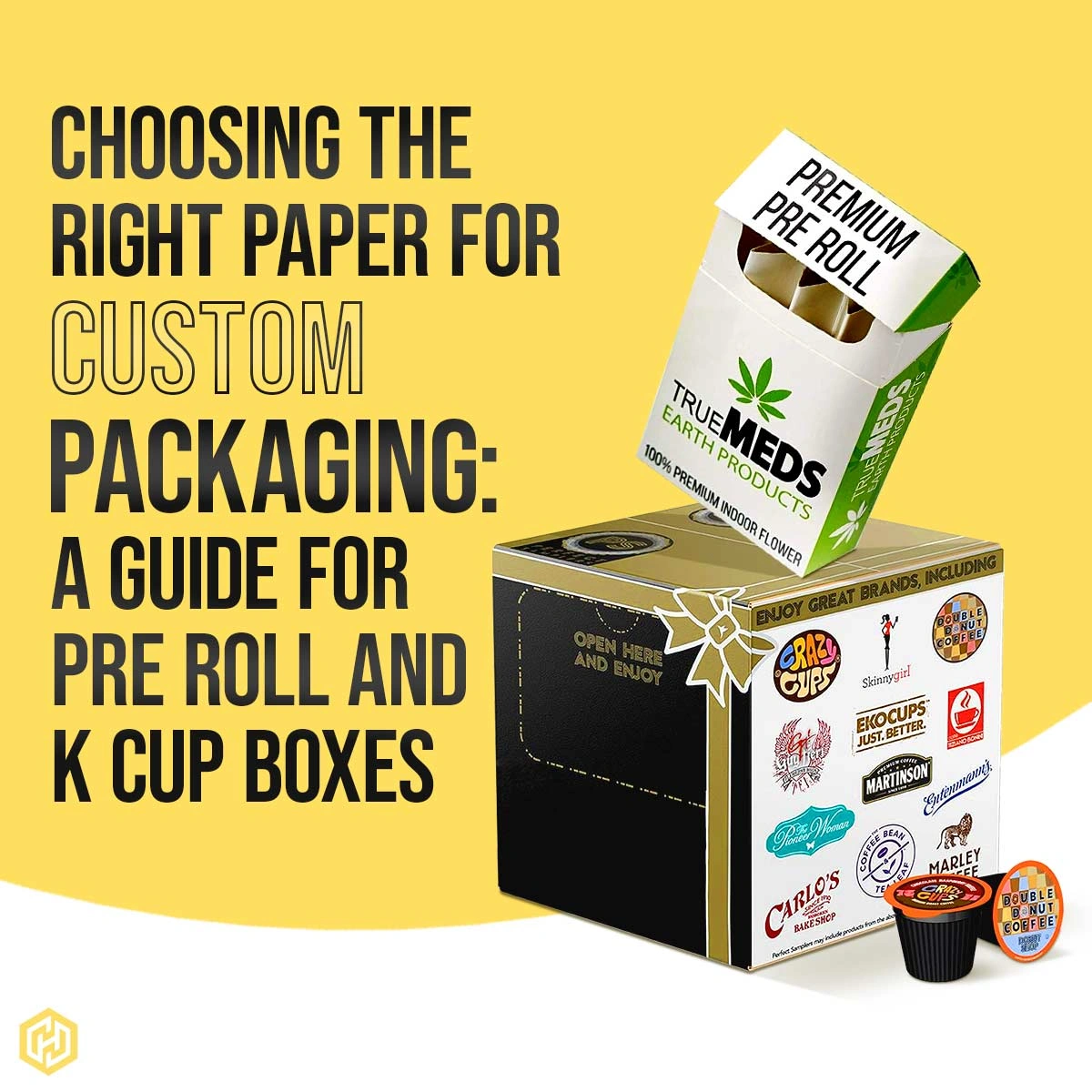

Choosing the Right Paper for Custom Packaging: A Guide for Pre Roll and K Cup Boxes

Why Paper Choice Matters in Custom Packaging

When it comes to creating custom packaging that stands out, the material you choose is just as important as the design itself. For brands selling products like custom pre roll boxes or custom K cup boxes, packaging is not just a way to hold and protect items, it’s a powerful tool for branding, customer experience, and sustainability.

Paper is at the heart of most packaging solutions. It shapes how your product feels in someone’s hands, how it looks on a shelf, and even how customers perceive your brand’s quality. Choosing the right paper can enhance your packaging’s appearance, boost durability, and even support your sustainability goals.

In this guide, we’ll break down everything you need to know about selecting the right paper for your custom packaging. We’ll focus on two popular types, custom pre roll boxes for the cannabis industry and custom K cup boxes for the beverage and retail market while exploring how different paper choices impact design, function, and business success.

- Understanding the Role of Paper in Packaging Design

Paper isn’t just the surface you print your logo on, it’s the foundation of your packaging. It affects the strength, structure, weight, and finish of the final box. For example:

- A lightweight paper might be perfect for small, single-use products but won’t hold up for heavier retail displays.

- A textured or premium-grade paper can instantly elevate your packaging, giving it a luxury feel.

- Sustainable, recycled paper appeals to eco-conscious consumers and aligns with modern brand values.

For custom pre roll boxes, paper often needs to balance strength and sophistication. The box should protect the delicate pre rolls while still looking premium. For custom K cup boxes, paper must be durable, printable, and able to support heavier contents without tearing or bending.

- Types of Paper Commonly Used in Custom Packaging

The paper you choose will depend on your product’s needs, your brand’s image, and your packaging budget. Here are some of the most common paper options:

- Cardstock

Cardstock is a popular choice for both custom pre roll boxes and custom K cup boxes. It’s thicker than regular paper and offers a smooth surface that’s ideal for high-quality printing. Brands often choose cardstock because:

- It’s sturdy enough to protect the product.

- It allows for vibrant, detailed printing.

- It’s versatile and works with many box styles.

- Kraft Paper

Kraft paper is the go-to for eco-friendly packaging. It’s made from recycled fibers and is known for its durability and natural, rustic appearance. Businesses choose kraft when they want to highlight sustainability or appeal to eco-conscious consumers. It’s especially popular for organic pre roll products or artisanal coffee pods.

- Corrugated Board

For larger or heavier packaging like bulk custom K cup boxes corrugated paperboard offers maximum strength. It has a fluted layer between two linerboards, giving it durability and shock resistance. It’s not as sleek as cardstock but ensures products stay protected during shipping and handling.

- Specialty Papers

Luxury brands often invest in specialty papers, such as textured, coated, or metallic finishes. These papers cost more but instantly communicate premium quality — ideal for high-end pre roll lines or premium coffee brands.

- How Paper Choice Affects Branding and Customer Perception

Consumers notice packaging long before they try your product. The right paper can make your brand appear luxurious, eco-friendly, minimalistic, or bold depending on your target market.

- For cannabis brands, premium textured paper or matte-coated cardstock can make your custom pre roll boxes feel sophisticated and trustworthy.

- For coffee brands, smooth, high-gloss cardstock with rich printing can make your custom K cup boxes pop on retail shelves.

- For eco-friendly companies, recycled kraft paper signals authenticity and responsibility.

The paper you choose becomes part of your brand story and customers often associate the quality of packaging with the quality of the product inside.

- Balancing Sustainability and Functionality

Sustainability is no longer optional. Many consumers actively choose brands that use environmentally friendly packaging. But choosing sustainable paper doesn’t mean sacrificing quality or aesthetics.

- Recycled paper and post-consumer waste (PCW) options are now available in high-quality finishes.

- Biodegradable coatings can replace traditional plastic laminates without compromising print quality.

- FSC-certified paper ensures your packaging is sourced responsibly.

For example, a company producing custom pre roll boxes can use recycled kraft with minimal ink for a natural, eco-luxury look. Similarly, a coffee brand can choose FSC-certified paperboard for their custom K cup boxes, reducing their environmental footprint while maintaining strength and durability.

- Matching Paper to Product: A Practical Breakdown

Here’s a quick guide to help you decide which paper might suit your specific needs:

| Product Type | Recommended Paper | Why It Works |

| Pre Roll Singles | Textured Cardstock or Coated Paper | Premium feel, detailed printing |

| Pre Roll Multipacks | Corrugated or Rigid Board | Extra strength for multiple items |

| Standard K Cup Box (12-24 pack) | Coated Cardstock or Kraft | Balance of print quality and durability |

| Bulk K Cup Shipping Boxes | Corrugated Board | Maximum protection during transport |

- The Role of Printing and Finishing in Final Results

Paper choice is the first step but how you print and finish your packaging also plays a huge role in the final product.

- Matte and gloss coatings can change the feel and visibility of your branding.

- Spot UV or foil stamping can highlight logos and make them stand out.

- Embossing or debossing adds a tactile layer that enhances perceived quality.

These techniques pair well with premium paper and help custom pre roll boxes and custom K cup boxes attract attention in competitive retail spaces.

- Tips for Choosing the Best Paper for Your Packaging

If you’re unsure which direction to take, here are some practical tips to guide your decision:

- Start with your product: Lightweight, fragile, or premium items might need sturdier, high-quality paper.

- Think about your customers: Are they looking for eco-friendly solutions, premium aesthetics, or affordability?

- Balance budget and quality: Premium papers are great for luxury products, but standard cardstock or kraft may be better for large-scale production.

- Consider storage and shipping: Durability matters if your packaging will travel long distances or be stacked on retail shelves.

- Why Work With Experts Like Haul Packaging

Choosing the right paper might seem simple, but the best results come from working with professionals who understand packaging inside and out. That’s where Haul Packaging comes in.

With years of experience designing and producing custom pre roll boxes, custom K cup boxes, and other custom packaging boxes, Haul Packaging helps brands find the perfect balance of style, strength, and sustainability. From selecting the right materials to ensuring flawless printing and finishing, our team guides you through every step of the packaging process.

Conclusion: Paper Is the Foundation of Great Packaging

At Haul Packaging, we know the paper you choose sets the tone for your entire packaging experience. It affects not just how your boxes look, but how they feel, how they protect your product, and how customers perceive your brand. Whether you’re designing sleek custom pre-roll boxes for a cannabis line or practical custom K-Cup boxes for retail shelves, selecting the right paper is a decision that shapes your brand identity.

Investing in high-quality, well-chosen paper isn’t just about packaging, it’s about creating a memorable first impression and building long-term trust with your customers.