Exploring Different Packaging Materials and How They Shape Products Like K Cup and Cigar Boxes

Why Material Choice Matters in Packaging

When people think about packaging, they often focus on design — the colors, fonts, and logos. But behind every great-looking package is something just as important: the material it’s made from. The type of material used in packaging not only determines how well a product is protected but also affects how it’s perceived by customers.

For brands that sell coffee pods or premium cigars, material choice can make or break the buying experience. Whether it’s sturdy cardboard for custom K cup boxes or luxurious rigid paperboard for custom cigar boxes, selecting the right material is about balancing durability, appearance, cost, and sustainability.

In this guide, we’ll explore the most common packaging materials, their unique qualities, and how each one plays a key role in protecting products and influencing customer decisions.

-

Cardboard – The Most Versatile and Popular Choice

Cardboard is one of the most widely used materials in the packaging industry and for good reason. It’s lightweight, cost-effective, and easy to customize. It can be cut, folded, printed, and finished in countless ways, making it ideal for a wide range of products.

For custom K cup boxes, cardboard is often the go-to material. It’s strong enough to protect the pods during shipping, yet light enough to keep packaging costs low. With the right printing and finishing, it can also be turned into a beautiful retail-ready box that showcases your brand perfectly.

For custom cigar boxes, thicker grades of cardboard (sometimes called chipboard or paperboard) are used to create a premium look without the weight or cost of wood. This option is ideal for brands that want to achieve a luxurious presentation while remaining eco-friendly and budget-conscious.

Advantages of cardboard packaging:

- Highly customizable (printing, finishes, die-cuts)

- Lightweight and cost-efficient

- Recyclable and environmentally friendly

- Strong enough for shipping and retail use

-

Corrugated Fiberboard – Strong and Durable Protection

When strength and durability are the top priorities, corrugated fiberboard is a top choice. It consists of multiple layers, two flat outer layers and a fluted inner layer, that provide excellent cushioning and resistance against impacts.

This material is commonly used for shipping boxes, subscription packaging, and bulk packaging. For businesses shipping custom K cup boxes in large quantities, corrugated board ensures that every product arrives safely. Even delicate products like cigars benefit from an extra layer of protection when shipped inside a corrugated outer box.

Why it’s a good choice:

- Exceptional strength for heavy or fragile products

- Great shock absorption during transit

- Can be combined with printed sleeves for branding

- Often made from recycled materials

While corrugated boxes might not always be used for direct retail display, they are crucial for ensuring the product’s journey from warehouse to customer is safe and damage-free.

-

Kraft Paper – Eco-Friendly and Naturally Appealing

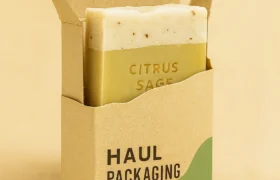

Sustainability is becoming a major factor in packaging decisions, and kraft paper is leading the trend. Made from natural wood pulp, it’s recyclable, biodegradable, and compostable, all while offering surprising strength and flexibility.

For custom K cup boxes, kraft packaging creates a clean, earthy, and natural aesthetic that appeals to environmentally conscious buyers. Many coffee brands use kraft finishes to emphasize their eco-friendly practices or organic sourcing.

Custom cigar boxes made with kraft paper, often paired with minimal printing or foil stamping, have a rustic yet premium look. This material works especially well for artisanal or small-batch cigar brands looking to differentiate themselves with authenticity and sustainability.

Benefits of kraft paper:

- 100% recyclable and biodegradable

- Has a natural, organic look

- Strong and durable despite its lightweight feel

- Works well for both rustic and premium branding styles

-

Rigid Paperboard – Luxury and Premium Presentation

If cardboard is the everyday packaging hero, rigid paperboard is its high-end sibling. Much thicker and sturdier than standard paperboard, rigid boxes are used for luxury items where presentation is as important as protection.

For custom cigar boxes, rigid paperboard is often the preferred material. Cigars are premium products, and customers expect the packaging to reflect that. A well-designed rigid box with foil stamping, embossing, or velvet lining can instantly elevate a brand’s image and create a memorable unboxing experience.

Although custom K cup boxes typically don’t require rigid packaging, specialty coffee brands launching limited-edition or gift sets may use it to create a more upscale feel.

Key advantages of rigid boxes:

- Premium appearance for high-value products

- Extremely durable and long-lasting

- Ideal for gift sets or collector’s editions

- Enhances perceived product value

-

Plastic – Practical but Less Sustainable

Plastic has long been used in packaging for its durability, flexibility, and moisture resistance. It’s often used as part of a larger packaging solution, such as windows on a box, inner trays, or protective seals.

In custom K cup boxes, small plastic inserts or liners can help hold pods in place, ensuring they don’t move during shipping or display. For custom cigar boxes, plastic might be used for airtight seals or protective wrapping to maintain freshness.

However, the growing demand for eco-friendly packaging has led many brands to minimize their use of plastic or switch to biodegradable alternatives. If you choose to use plastic, doing so strategically and in limited amounts is often the best approach.

Pros of using plastic:

- Excellent barrier against moisture and air

- Lightweight and durable

- Good for protective inserts or display windows

-

Wood – A Premium and Traditional Option

Wood packaging is less common due to cost, but it’s still used for luxury items, especially cigars. Traditional wooden custom cigar boxes are considered a mark of craftsmanship and quality. They offer a timeless appeal and help preserve cigars by maintaining the ideal humidity and temperature.

Some brands use wood veneers or wood-textured finishes to achieve the same effect at a lower cost. For coffee, wood is rarely used, but premium gift sets might incorporate wooden elements for a more exclusive presentation.

Benefits of wood packaging:

- Extremely durable and long-lasting

- Offers a classic, high-end appearance

- Ideal for premium or collectible products

Choosing the Right Material for Your Brand

There’s no single “best” material for packaging — it all depends on your product, target audience, and brand identity. Here’s a quick guide to help you choose:

- For affordability and versatility: Cardboard or kraft paper

- For shipping and protection: Corrugated fiberboard

- For luxury and premium appeal: Rigid paperboard or wood

- For sustainability: Kraft paper or recycled cardboard

- For added protection and structure: Plastic (as inserts or seals)

It’s also worth considering the message you want to send. Eco-friendly materials communicate responsibility, while luxury materials communicate exclusivity. Combining materials such as a rigid exterior with a kraft insert, can also balance cost, appearance, and performance.

Final Thoughts: The Role of Materials in Branding and Customer Experience

Packaging is more than just a container, it’s a powerful tool that shapes how customers see your brand and experience your product. Whether you’re designing custom Packaging boxes that need to stand out on a grocery shelf or custom cigar boxes that convey craftsmanship and tradition, the material you choose speaks volumes.

From sustainable kraft paper to premium rigid board, each option brings its own strengths and story to the table. By understanding the purpose and potential of each, you can create packaging that not only protects your products but also builds trust, loyalty, and lasting impressions.

Frequently Asked Questions

1. What is the typical Minimum Order Quantity (MOQ) for custom cigar boxes?

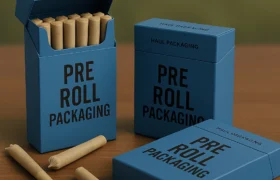

At Haul Packaging in the USA, we understand the needs of growing brands. Our standard Minimum Order Quantity (MOQ) starts at an accessible 100 boxes, making custom packaging feasible for businesses of all sizes. We also offer flexible options and are happy to discuss your specific project to find a solution that works for you, whether you’re launching a new line or fulfilling a large order.

2. How customizable are the boxes? What are my options with a US-based manufacturer?

As a leading US-based manufacturer, Haul Packaging offers extensive customization to make your brand stand out. You have complete control over:

- Dimensions & Structure: We create boxes tailored to your cigars’ exact specifications.

- Materials: Choose from durable cardboard, eco-friendly Kraft paper, sturdy corrugated, or luxury rigid boxes.

- Printing & Finishing: Utilize high-quality printing with options for foil stamping, embossing, or spot UV coating for a premium finish.

- Interior Design: Add custom inserts, cedar lining, or slots for humidity packs to ensure perfect presentation and protection.

3. What is the average turnaround time from order to delivery?

Our typical turnaround time is 2 to 3 weeks from final proof approval to delivery. Being a USA-based company like Haul Packaging often allows for more streamlined communication and faster production cycles compared to overseas suppliers. The process includes design proofing, production, and shipping. We also provide rush service options for time-sensitive projects.

4. How do custom boxes protect the cigars during storage and shipping?

Haul Packaging designs boxes with protection as a top priority. We use high-grade, durable materials engineered to resist crushing during transit. Our boxes feature a tight-seal closure to shield cigars from air, light, and physical damage. For added security, we offer options like reinforced corners and custom-fit inserts that prevent movement, ensuring your products arrive in perfect condition.

5. Can you include features to help maintain cigar freshness?

Yes, absolutely. Haul Packaging offers several features to help preserve the quality and freshness of your cigars. You can opt for Spanish cedar linings to naturally regulate humidity and add a classic aroma. We can also design boxes with integrated slots for humidity control packs (like Boveda) and ensure a tight-fitting lid to maintain a stable internal environment for your products.